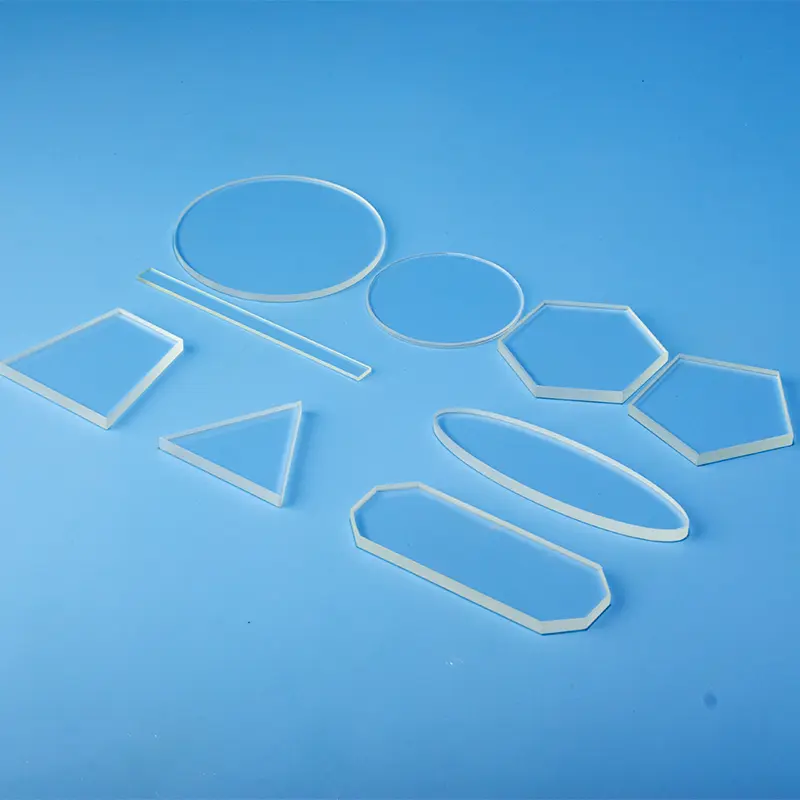

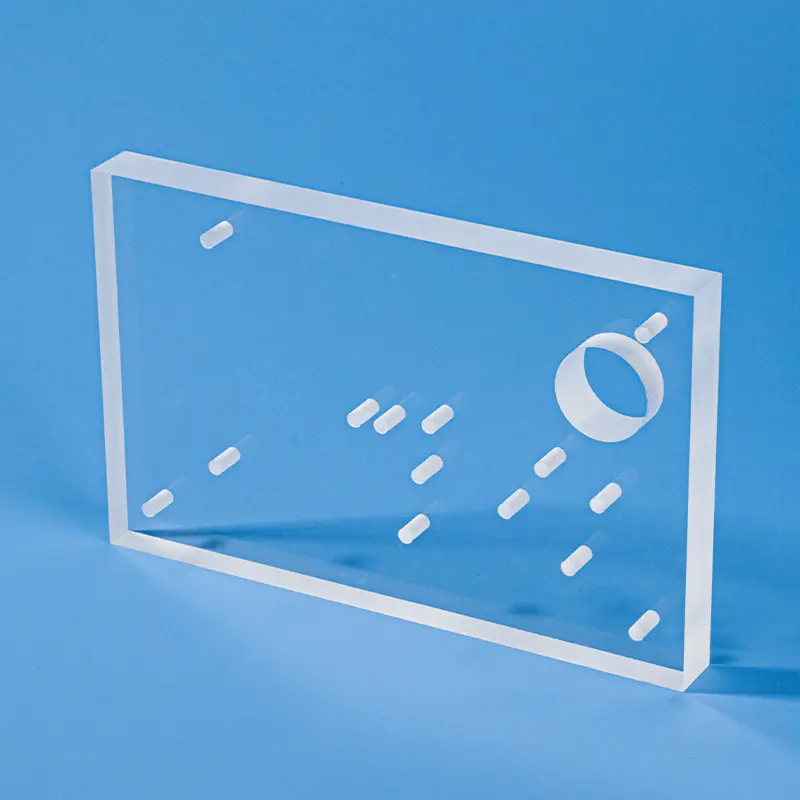

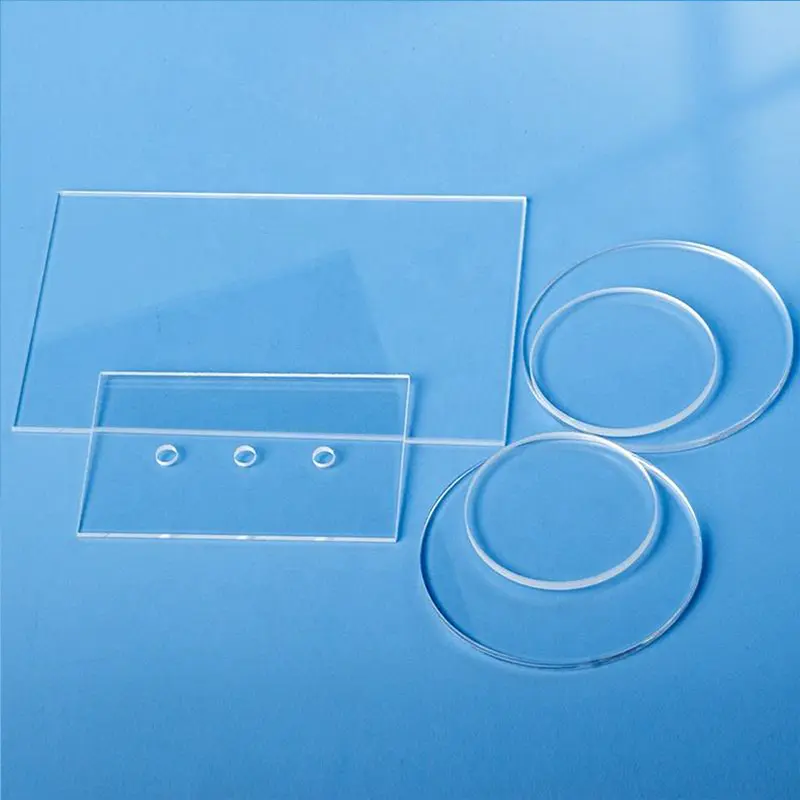

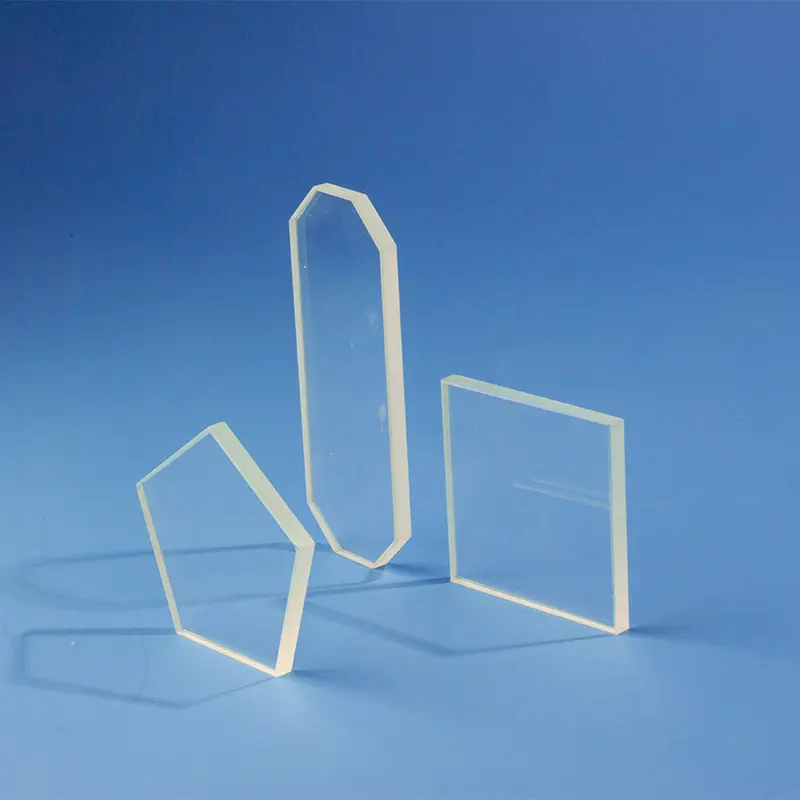

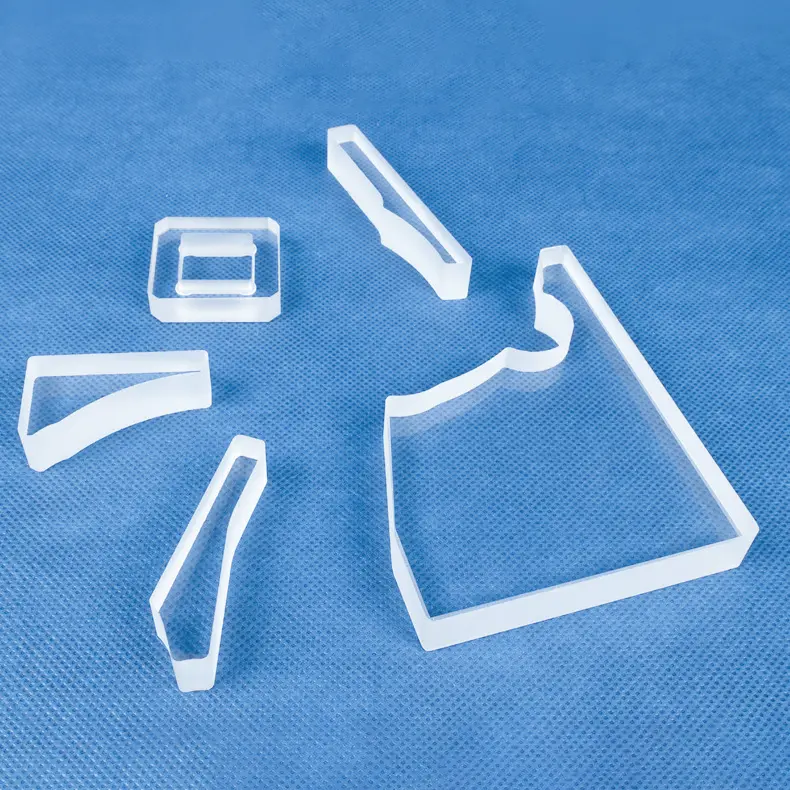

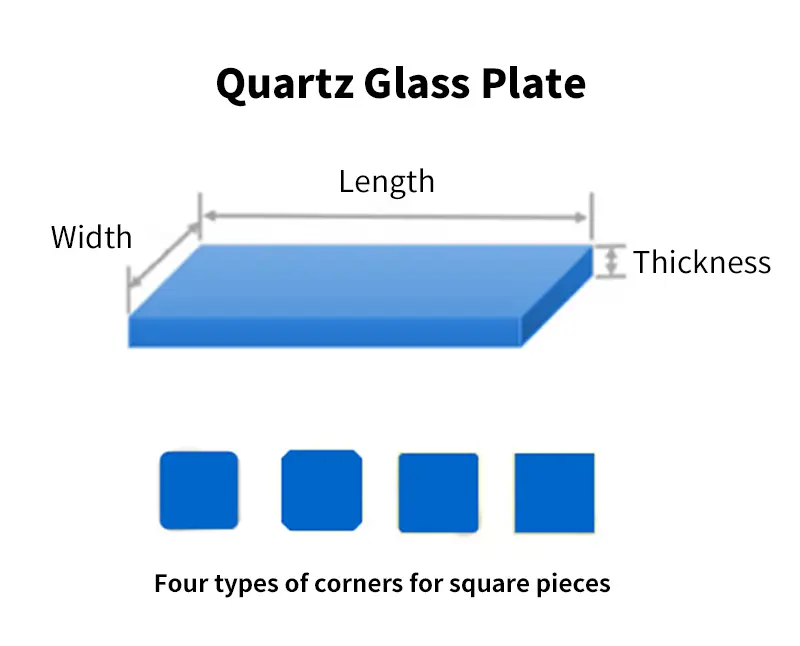

Nos plaques de verre de quartz sont des composants usinés avec précision, fabriqués à partir de silice fondue de haute pureté, offrant une transparence et une clarté optique exceptionnelles. Ces feuilles robustes se caractérisent par une résistance supérieure aux températures élevées et aux produits chimiques agressifs, ainsi qu'un très faible coefficient de dilatation thermique. Dotées d'excellentes propriétés d'isolation électrique, nos plaques de quartz sont indispensables pour les applications exigeantes dans la communication par fibre optique, la fabrication de semi-conducteurs et les équipements médicaux. Elles sont disponibles dans une large gamme de dimensions standard et d'épaisseurs pour répondre à vos exigences techniques spécifiques.

| Longueur | Largeur | Épaisseur |

|---|---|---|

| 5mm | 5mm | 1mm |

| 10mm | 10mm | 0.5mm |

| 10mm | 10mm | 1mm |

| 10mm | 10mm | 2mm |

| 12mm | 12mm | 1mm |

| 15mm | 15mm | 0.5mm |

| 15mm | 15mm | 1mm |

| 15mm | 15mm | 2mm |

| 15mm | 15mm | 3mm |

| 20mm | 20mm | 0.5mm |

| 20mm | 20mm | 1mm |

| 20mm | 20mm | 2mm |

| 20mm | 20mm | 3mm |

| 25mm | 25mm | 0.5mm |

| 25mm | 25mm | 1mm |

| 25mm | 25mm | 2mm |

| 25mm | 25mm | 3mm |

| 30mm | 30mm | 0.5mm |

| 30mm | 30mm | 1mm |

| 30mm | 30mm | 2mm |

| 30mm | 30mm | 3mm |

| 35mm | 35mm | 1mm |

| 35mm | 35mm | 2mm |

| 35mm | 35mm | 3mm |

| 40mm | 40mm | 0.5mm |

| 40mm | 40mm | 1mm |

| 40mm | 40mm | 2mm |

| 40mm | 40mm | 3mm |

| 45mm | 45mm | 1mm |

| 45mm | 12mm | 1mm |

| 45mm | 12mm | 2mm |

| 35mm | 35mm | 2mm |

| 50mm | 50mm | 0.5mm |

| 50mm | 50mm | 1mm |

| 50mm | 50mm | 2mm |

| 50mm | 50mm | 3mm |

| 50mm | 50mm | 4mm |

| 50mm | 50mm | 5mm |

| 60mm | 60mm | 1mm |

| 60mm | 60mm | 2mm |

| 60mm | 60mm | 3mm |

| 70mm | 70mm | 2mm |

| 70mm | 70mm | 3mm |

| 70mm | 70mm | 5mm |

| 75mm | 25mm | 0.5mm |

| 75mm | 25mm | 1mm |

| 75mm | 25mm | 2mm |

| 80mm | 80mm | 1mm |

| 80mm | 80mm | 2mm |

| 80mm | 80mm | 3mm |

| 80mm | 80mm | 4mm |

| 100mm | 100mm | 1mm |

| 100mm | 100mm | 1.5mm |

| 100mm | 100mm | 2mm |

| 100mm | 100mm | 3mm |

| 100mm | 100mm | 5mm |

| 100mm | 100mm | 0.5mm |

| 100mm | 100mm | 1mm |

| 100mm | 100mm | 2mm |

| 100mm | 100mm | 3mm |

| 100mm | 100mm | 5mm |

| 150mm | 150mm | 2mm |

| 150mm | 150mm | 3mm |

| 150mm | 150mm | 5mm |

- Méthode de paiement: Par virement bancaire ou paiement anticipé, selon la quantité de la commande

- Délai de livraison: Selon la quantité de la commande

- Méthode de transport: Fret maritime ou fret aérien, selon le client

Remarques:

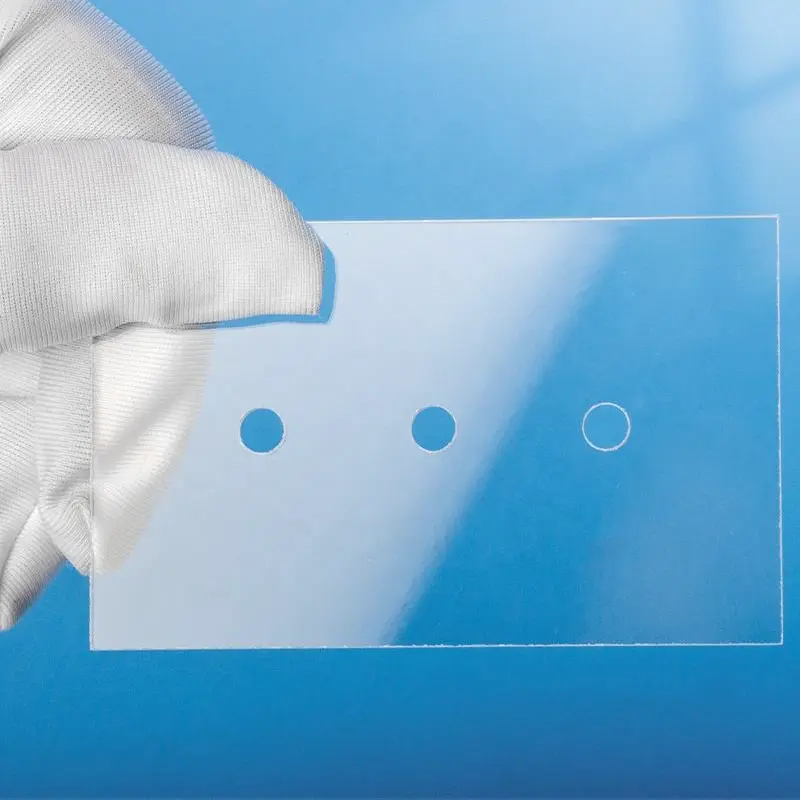

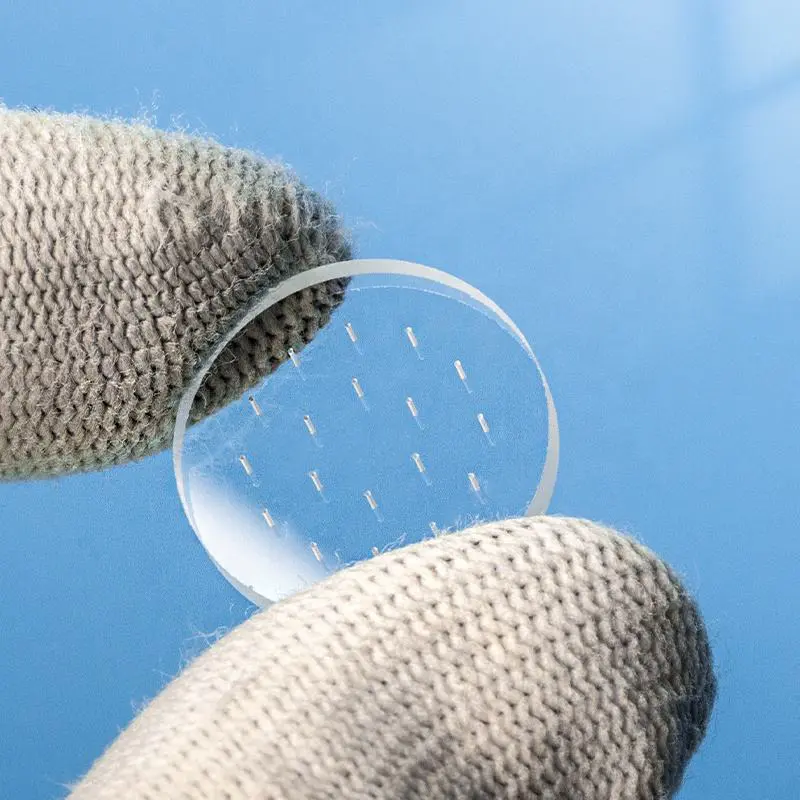

Pour confirmer la commande, les paramètres suivants doivent être fournis : ① Carré : longueur, largeur, épaisseur ② Cercle : diamètre, épaisseur ③ Précision ④ Quantité

| Contenu des propriétés | Valeurs des propriétés |

|---|---|

| SiO2 | 99.99% |

| Densité | 2,2×10³ kg/cm³ |

| Dureté | Dureté Mohs de 5,5 à 6,5; Dureté Knoop 570 (sous une charge de 100g) |

| Résistance à la traction | 4,8 × 10⁷ Pa (48 N/mm² ou 48 MPa); 7 000 psi |

| Résistance à la compression | >1.1×10⁹ Pa (160,000 psi) |

| Coefficient de dilatation thermique | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| Conductivité thermique | 1,4 W/m-°C |

| Chaleur spécifique | 670 J/kg-°C |

| Point de ramollissement | 1730°C (3146°F) |

| Point de recuit | 1210°C (2210°F) |

| Point de contrainte | 1120°C (2048°F) |

| Température de travail | 1200°C (2192°F) |

| Résistivité électrique | 7×10⁷ ohm cm (350°C) |

| Taille | Sur mesure |

| Logo | Personnalisation du logo disponible |

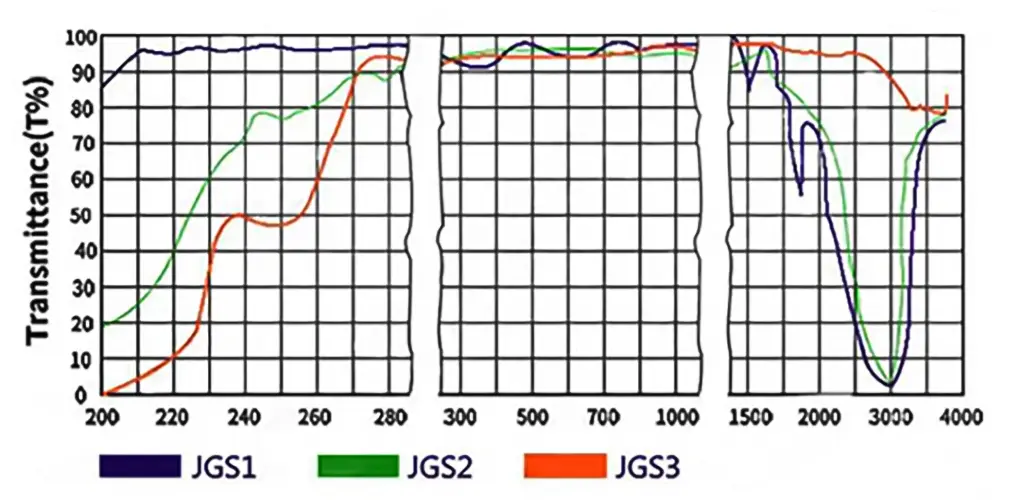

JGS1

Communément appelé silice fondue de qualité UV, ce matériau présente une dispersion exceptionnellement faible et une très haute transmission dans la gamme spectrale ultraviolette (UV).

JGS2

Similaire au JGS1, mais il peut y avoir des variations dans certains paramètres de performance spécifiques tels que la transmission et le coefficient de dilatation thermique, selon les standards du fabricant

JGS3

Ce matériau est généralement utilisé dans des applications nécessitant une pureté plus élevée ou des caractéristiques de performance spécialisées. Les paramètres de performance spécifiques peuvent varier en fonction du fabricant

Caractéristiques de dispersion

Les feuilles de quartz JGS1 et JGS2 présentent d'excellentes propriétés de dispersion dans la gamme spectrale ultraviolette (UV), séparant efficacement la lumière UV de différentes longueurs d'onde. Cela les rend idéales pour la fabrication de composants optiques haute performance.

Transmittance

Les trois types de feuilles de quartz présentent une haute transmission à la lumière UV, en particulier dans des gammes de longueurs d'onde spécifiques. Par exemple, le JGS1 a une très haute transmission de 185 nm à 2 500 nm. Cela en fait les matériaux privilégiés pour la fabrication de lasers UV, de spectromètres UV et de filtres optiques.

Stabilité chimique

Les plaques de quartz possèdent une excellente stabilité chimique et peuvent résister à des conditions extrêmes, notamment aux acides, aux alcalins et aux hautes températures. Par conséquent, elles conviennent à la fabrication de réacteurs chimiques, de fenêtres de fours à haute température et d'instruments d'analyse chimique.

Faible coefficient d'expansion thermique

Ces feuilles de quartz ont de très faibles coefficients de dilatation thermique, montrant une réponse minimale aux variations de température. Cela est crucial pour la stabilité des composants optiques de haute précision.

Scénario d'application

Les plaques de quartz présentent d'excellentes propriétés de résistance à haute température, de résistance à la corrosion, de stabilité thermique et de transmittance lumineuse. Leur point de ramollissement est d'environ 1730 °C, et elles peuvent être utilisées en continu à 1100 °C, avec une utilisation à court terme pouvant atteindre 1450 °C. Le verre de quartz est très résistant aux acides, à l'exception de l'acide fluorhydrique, et montre une haute résistance aux réactions chimiques avec la plupart des autres acides. Les plaques de quartz ont un coefficient d'expansion thermique très bas, leur permettant de résister à des changements de température rapides sans se briser. Elles présentent également une bonne transmittance lumineuse dans tout le spectre UV à IR, avec une transmittance de la lumière visible dépassant 93 %.

Sur la base des propriétés optiques, les plaques de quartz sont classées en trois catégories : verre optique en quartz ultraviolet éloigné (FUV) (JGS1), verre optique en quartz ultraviolet (UV) (JGS2) et verre optique en quartz infrarouge (IR) (JGS3). Ces différents types de verre en quartz présentent des variations de transparence, de positions de bandes d'absorption, etc., dans les plages spectrales UV et visibles.

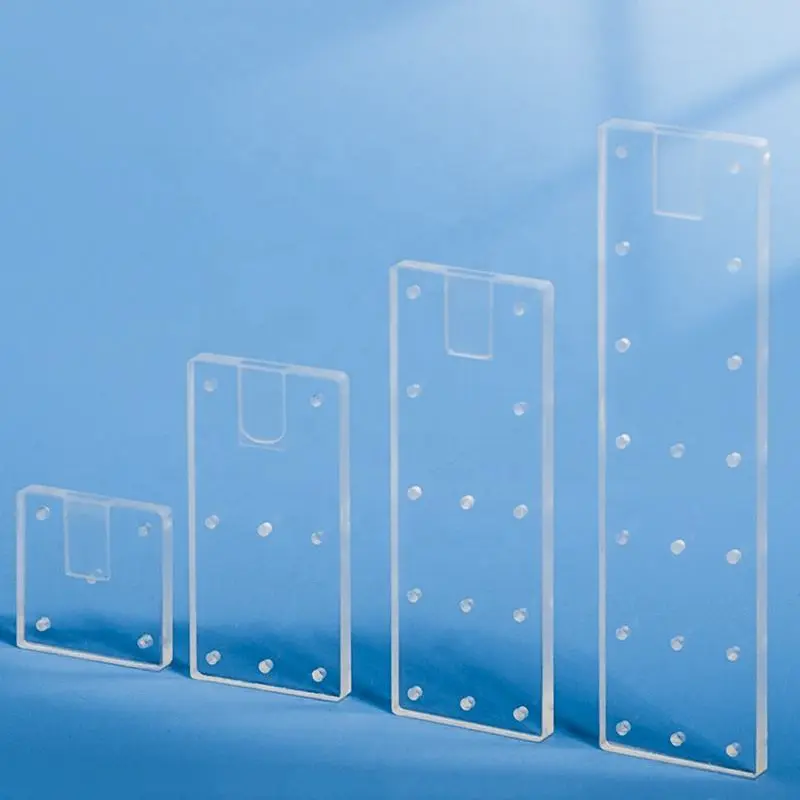

Le traitement des plaques de quartz comprend des étapes de traitement brut telles que le tri des matières premières, le collage de barres, la découpe de cristaux germes et l'arrondissement. Cela est suivi par des étapes de meulage, telles que le meulage grossier, le meulage moyen et le meulage fin. Par la suite, des processus de polissage et de nettoyage sont réalisés pour garantir la qualité de surface et la stabilité des plaquettes. Enfin, le montage et le collage sont effectués en fixant les plaques de quartz avec des électrodes appliquées et en appliquant un adhésif conducteur aux points de contact entre les électrodes et les coussinets métalliques pour établir une connexion électrique.

Questions fréquemment posées

Nous sommes spécialisés dans la fabrication intégrée de composants en verre de quartz de haute pureté. Nos principales gammes de produits comprennent :

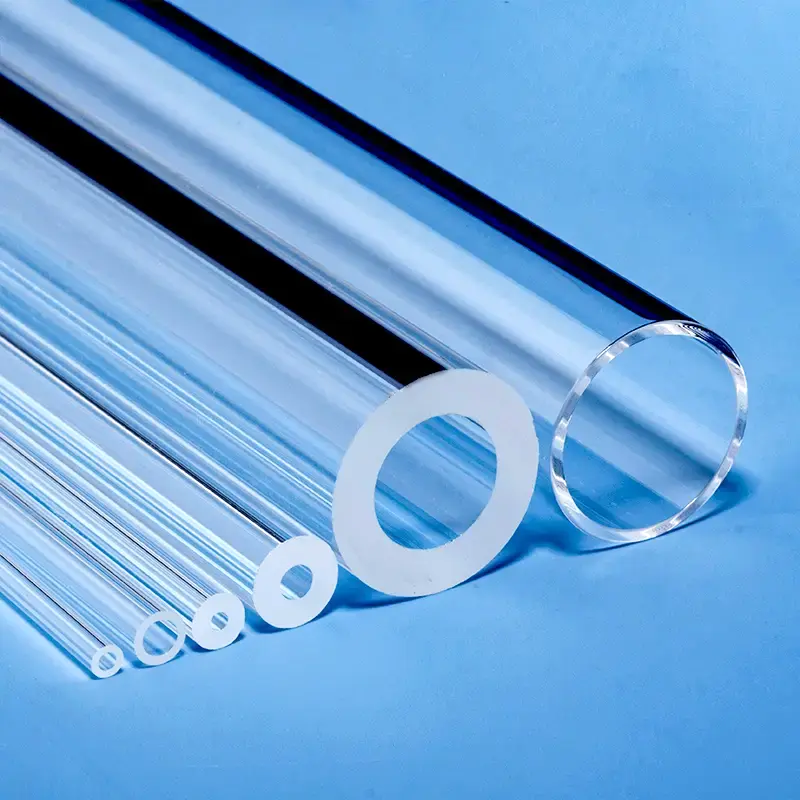

Tubes et barres de quartz: Une large gamme de diamètres et de spécifications.

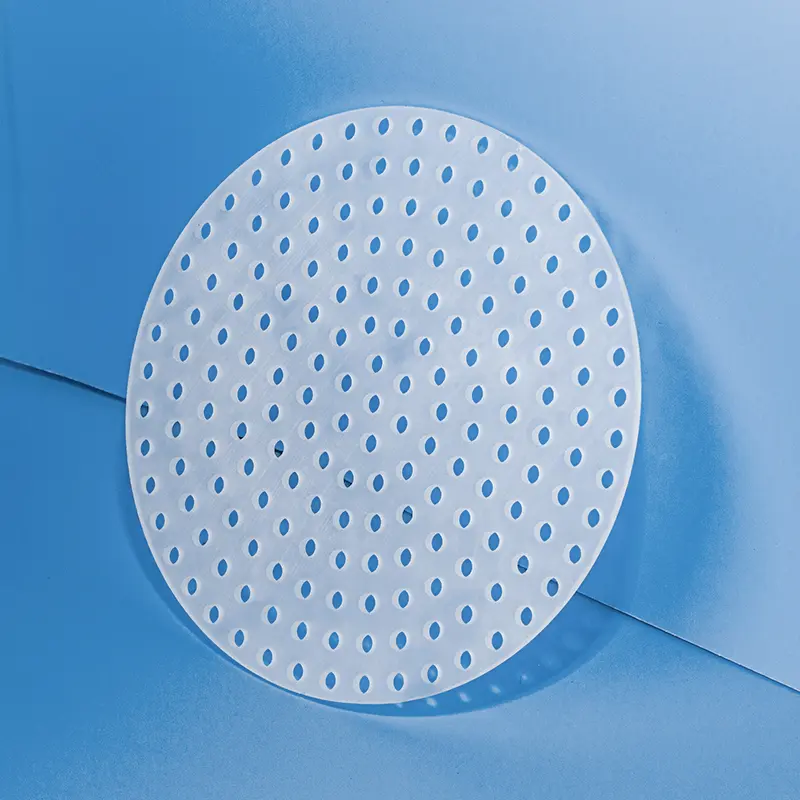

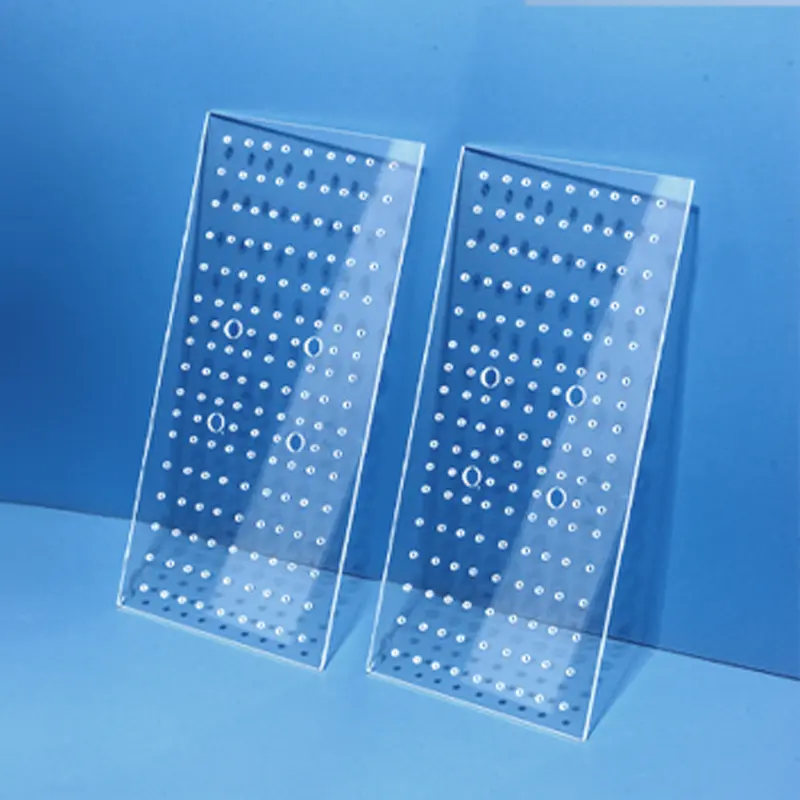

Plaques et disques de quartz: Découpés et polis avec précision pour usages optiques et industriels.

Verrerie de laboratoire en quartz: Une gamme complète de verrerie standard et sur mesure, incluant béchers, fioles et nacelles.

Quartz de qualité semi-conducteur: Composants de haute pureté tels que les tubes de traitement et les porteurs pour la fabrication de semi-conducteurs.

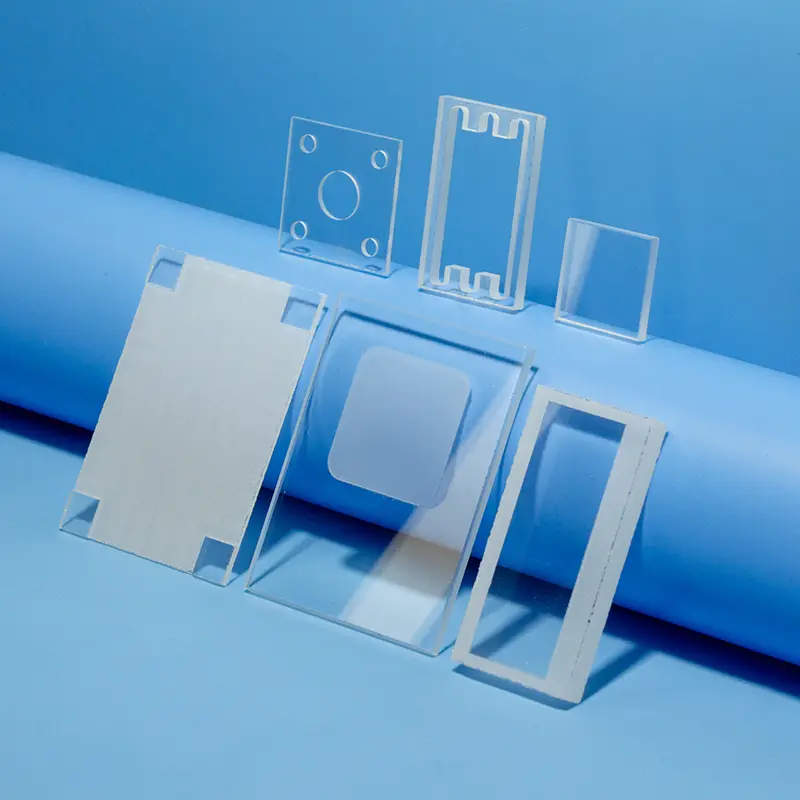

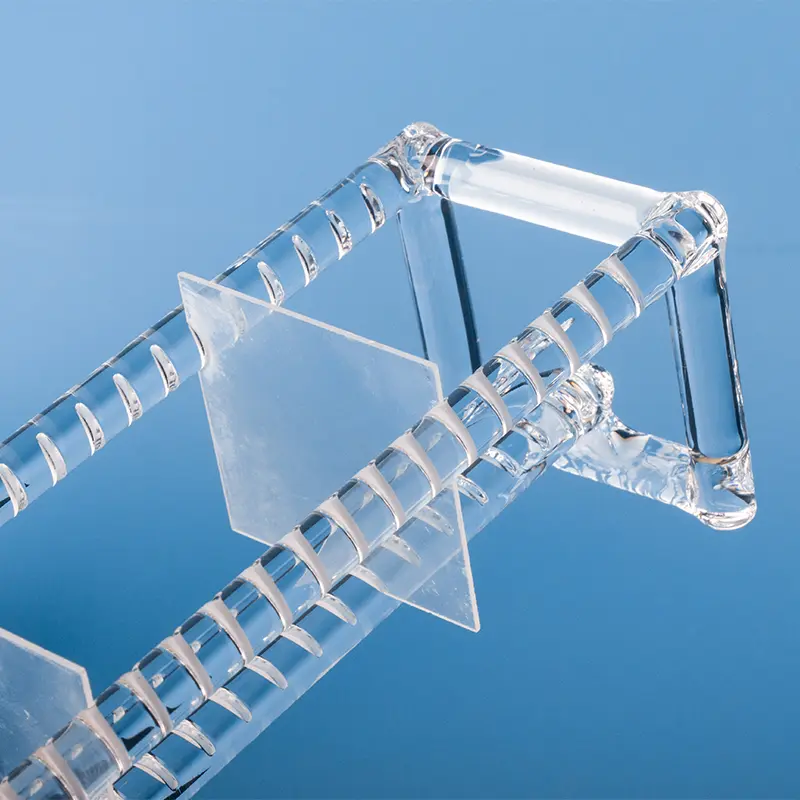

Composants fabriqués sur mesure: Nous pouvons produire des pièces complexes adaptées à vos conceptions et spécifications uniques.

Oui. La fabrication sur mesure est au cœur de notre activité. Forts de plus d'une décennie d'expérience spécialisée, nous nous associons à des entreprises pour leur offrir des services OEM/ODM experts. Nos capacités incluent le soudage, la rectification, le perçage, le polissage, le pliage et d'autres techniques d'usinage de précision, afin de créer des composants qui répondent précisément à vos exigences.

La qualité est primordiale dans notre processus de fabrication. Nous sommes un fabricant certifié ISO 9001:2015, garantissant que nos processus répondent aux normes internationales de gestion de la qualité.Nos produits subissent également des tests SGS rigoureux pour leur pureté et leurs performances. Nous utilisons des matières premières de haute pureté (jusqu'à 99,998% de SiO2) pour produire des articles en quartz fondu et en silice fondue dotés d'une stabilité thermique exceptionnelle, d'une résistance aux températures élevées et d'une inertie chimique.

Nous avons rationalisé notre processus pour qu'il soit le plus efficace possible :

Soumettez votre demande de devis (RFQ) : Envoyez-nous vos dessins techniques, spécifications et exigences via notre formulaire de contact sur le site web ou par e-mail.

Réponse rapide : Vous pouvez vous attendre à une première réponse en quelques minutes et à une communication détaillée dans la demi-heure.

Conception & Proposition : Nous vous soumettrons une proposition de conception détaillée et un devis compétitif sous 24 heures.

Prototypage & Production : Dès approbation, nous passons rapidement du prototypage à la production à grande échelle afin de respecter vos délais.

Un partenariat avec Aoxin Quartz offre plusieurs avantages clés :

Expertise avérée : Avec plus de 10 ans d'expérience dans l'industrie, nous possédons les connaissances techniques nécessaires pour relever les défis complexes.

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

Valeur compétitive : Situés dans un pôle majeur de production de quartz, nous tirons parti d'une chaîne d'approvisionnement efficace et d'une fabrication avancée pour offrir une qualité exceptionnelle à un prix compétitif.</span

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.