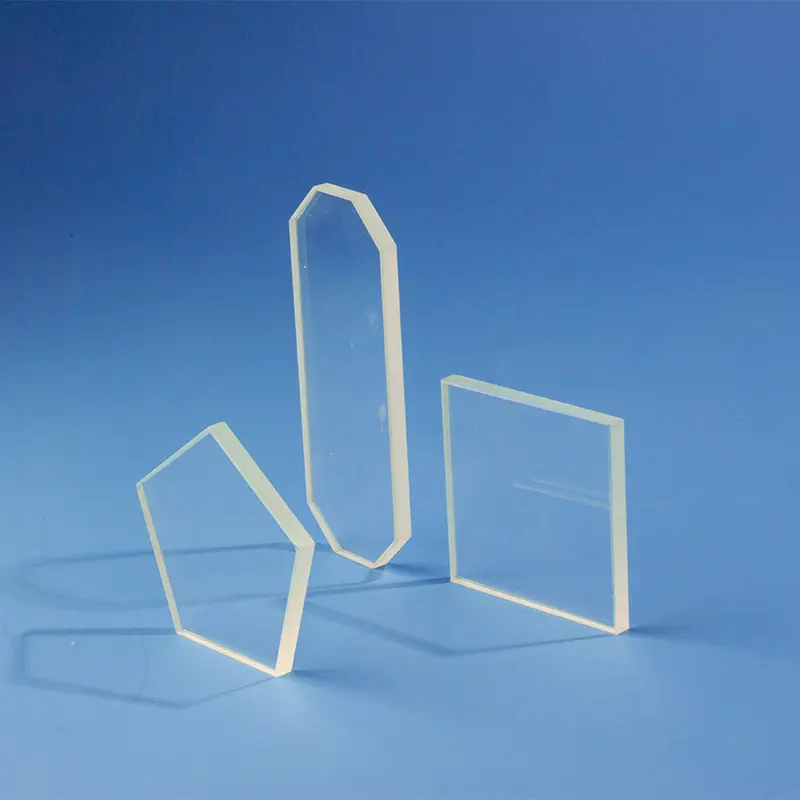

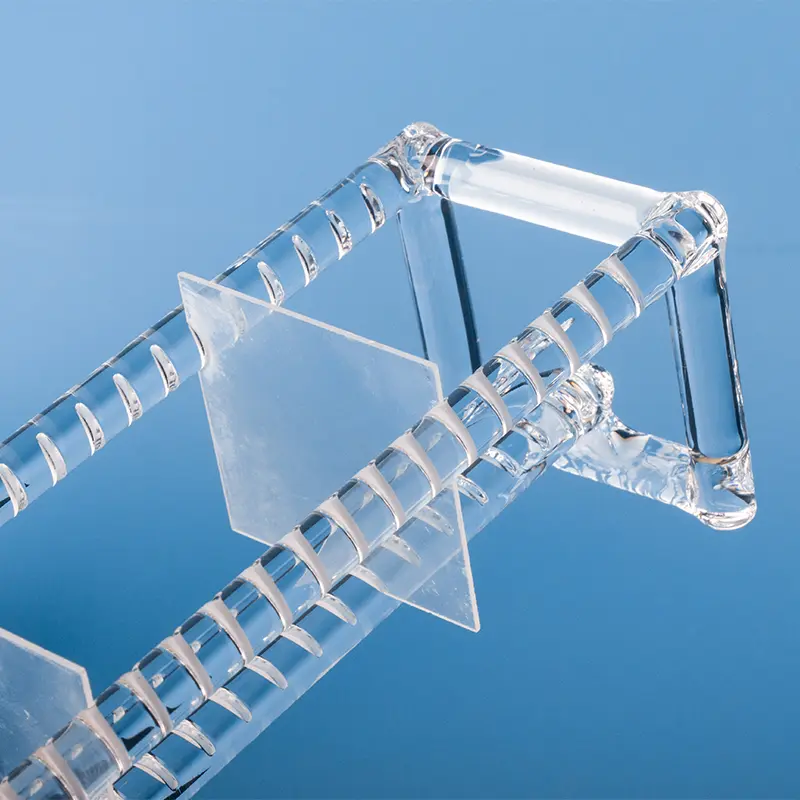

当社の石英フランジ(溶融石英フランジとも呼ばれる)は、極めて高い純度、耐熱性、真空適合性が必要な重要用途向けに精密に設計されています。半導体、光学、ラボ機器に最適で、信頼性が高く耐腐食性のある接続を保証します。お客様の正確な仕様に合わせてカスタム設計も可能です。

| 特性内容 | 特性値 |

|---|---|

| SiO2 | 99.99% |

| 密度 | 2.2×10³ kg/cm³ |

| 硬度 | モース硬度 5.5~6.5; ヌープ硬度 570 (荷重100g) |

| 引張強度 | 4.8 × 10⁷ Pa (48 N/mm² または 48 MPa); 7,000 psi |

| 圧縮強度 | >1.1×10⁹ Pa (160,000 psi) |

| 熱膨張係数 | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| 熱伝導率 | 1.4 W/m-°C |

| 比熱 | 670 J/kg-°C |

| 軟化点 | 1730度C(3146度F) |

| 徐冷点 | 1210度C(2210度F) |

| 歪点 | 1120度C(2048度F) |

| 使用温度 | 1200°C |

| 電気抵抗率 | 7×10⁷Ωcm (350°C) |

| サイズ | カスタマイズ対応 |

| ロゴ | ロゴのカスタマイズ対応 |

高温性能

石英フランジは、通常1000°Cを超える極めて高い温度に耐えることができるため、高温蒸気配管や溶融金属輸送システムのような高温環境に適しています

優れた化学的安定性

石英フランジは、強酸、強塩基、有機溶媒を含む様々な化学物質に対して優れた耐性を示すため、化学産業および医薬品産業で高く評価されています

高純度材料

石英フランジは高純度石英ガラスから製造されており、製品を汚染する可能性のある粒子や化学物質を放出しないため、半導体およびマイクロエレクトロニクス産業のクリーンルーム環境での使用が可能です

良好な機械的強度と耐久性

石英フランジは良好な機械的強度と耐久性を備えており、繰り返される温度および圧力変動下でも構造的完全性を維持し、それによって装置の寿命を延ばします

アプリケーションシナリオ

石英フランジの主要材料は高純度溶融石英ガラスであり、これは卓越した耐食性および高温特性を示します。強酸、強塩基、有機溶剤を含む様々な化学物質の侵食に効果的に耐えることができ、かつ高温環境(通常1000°C以上)においても変形や溶融することなく安定性を維持します。

石英フランジは、化学処理、石油化学、電子・電気、食品製造などの産業で幅広く使用されています。化学および石油化学産業では、高温かつ腐食性の媒体が関わる配管接続に利用されます。電子・電気産業では、LEDチップ製造や太陽電池製造における精密な配管接続に用いられます。食品製造分野では、わずかに腐食性のある材料の輸送に使用され、食品の安全性を確保します。

石英フランジの保守および交換サイクルは、稼働環境、温度、圧力、関与する化学媒体の種類を含む複数の要因に依存します。一般的に、石英フランジが適切に使用され、定期的にメンテナンスされていれば、その耐用年数はかなり長くなります。しかし、使用頻度が増すにつれて、摩耗、汚染、または微細な亀裂の形成により、徐々に性能が低下する可能性があります。このような問題が発生した場合には、交換が必要となります。具体的な保守および交換サイクルは、実際の使用条件と製造元の推奨事項に基づいて決定されるべきです。

よくある質問

当社は、高純度石英ガラス部品の一貫製造を専門としております。主な製品ラインナップは以下の通りです:

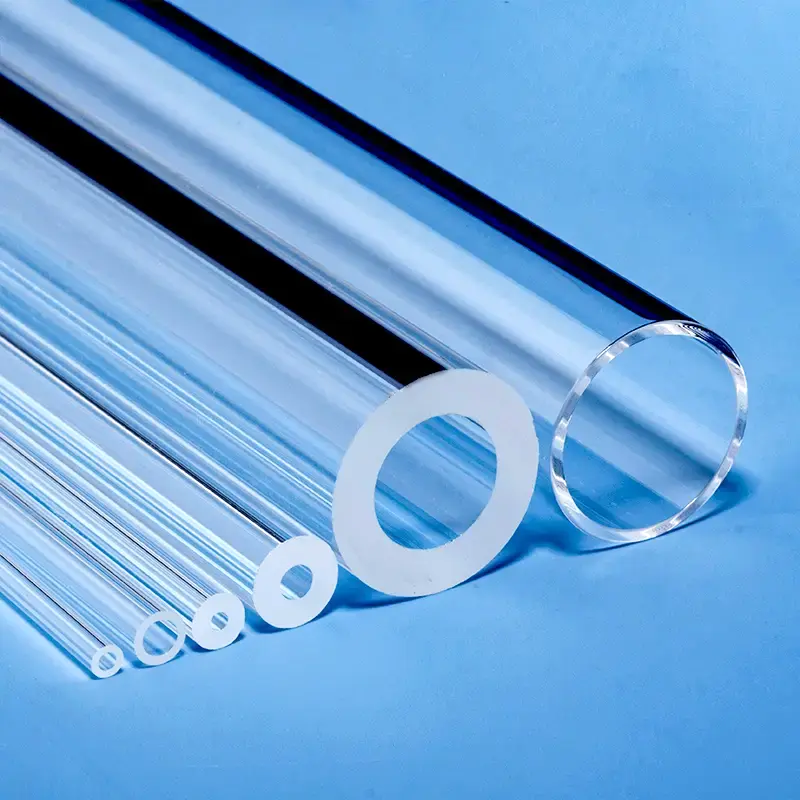

石英管・石英棒: 幅広い直径と仕様。

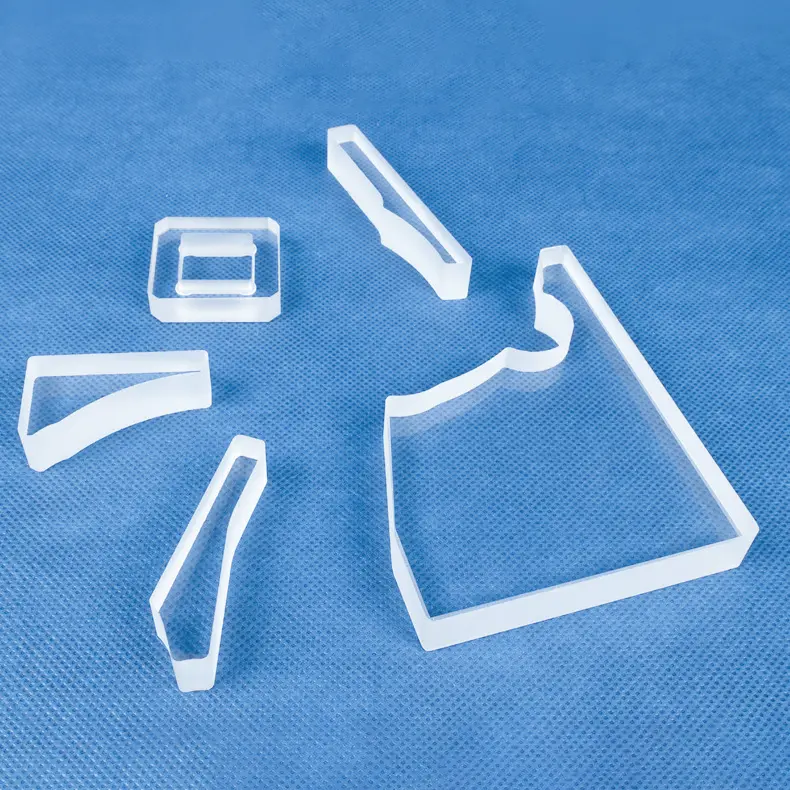

石英プレート・ディスク: 光学および工業用途向けに精密に切断・研磨。

石英実験器具: ビーカー、フラスコ、ボートなど、標準品から特注品まで幅広い種類のガラス器具。

半導体グレード石英: 半導体製造用のプロセスチューブやキャリアなどの高純度部品。

特注加工部品: お客様固有の設計および仕様に合わせて、複雑な部品を製造できます。

はい。特注加工(カスタム加工)は、当社の事業の中核です。10年以上にわたる専門的な経験を活かし、お客様企業と提携し、専門的なOEM/ODMサービスを提供しております。当社の加工技術には、溶接、研削、穴あけ、研磨、曲げ加工、その他さまざまな精密加工技術が含まれており、お客様の厳密なご要望にお応えする部品を製造いたします。

品質は当社の製造プロセスにおいて最も重要です。当社はISO 9001:2015認証取得メーカーであり、当社のプロセスが国際的な品質管理基準を満たしていることを保証します。また、当社の製品は純度と性能に関して厳格なSGS試験を受けています。当社は高純度原材料(SiO2 99.998%まで)を使用し、優れた熱安定性、高温耐性、化学的不活性を持つ溶融石英および溶融シリカ製品を製造しています。

当社はプロセスを最大限に効率化しました:

RFQ(見積依頼)を提出:ウェブサイトのお問い合わせフォームまたはEメールで、技術図面、仕様、要件をお送りください。

迅速な対応: 数分以内に初回返信を、30分以内に詳細なご連絡を差し上げます。

設計・提案:24時間以内に詳細な設計提案と競争力のある見積もりをお届けします。

試作・生産:承認後、お客様の納期に間に合わせるため、迅速に試作から本格的な量産へと移行いたします。

Aoxin Quartzとの提携には、いくつかの重要なメリットがあります:

実証された専門知識:業界で10年以上の経験を持つ当社には、複雑な課題に取り組むための技術的知見があります。

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

競争力のある価値:主要な石英生産拠点に位置することで、効率的なサプライチェーンと先進的な製造技術を活用し、競争力のある価格で卓越した品質を提供しています。

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.