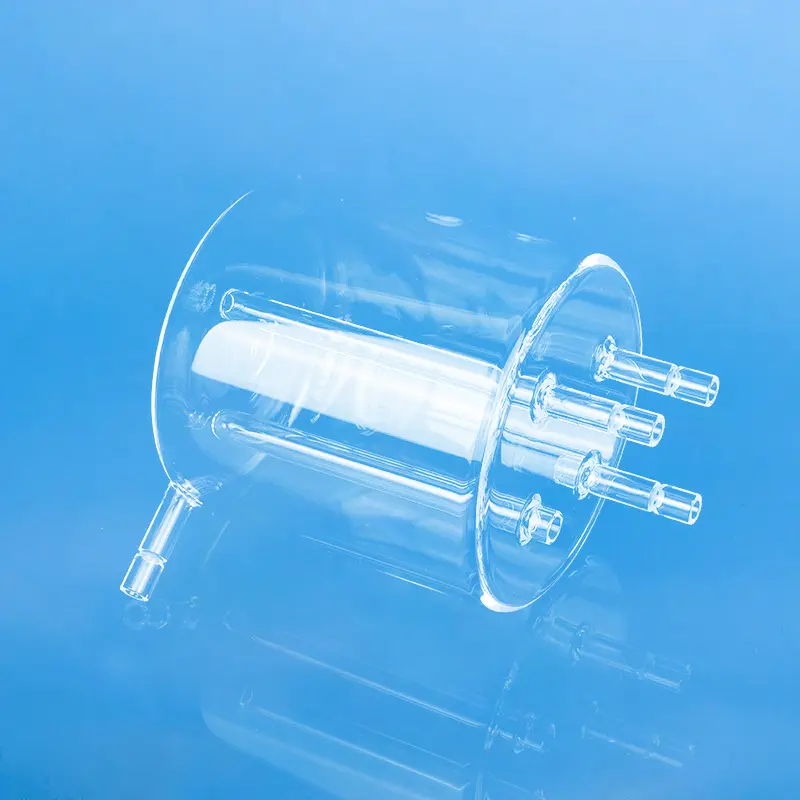

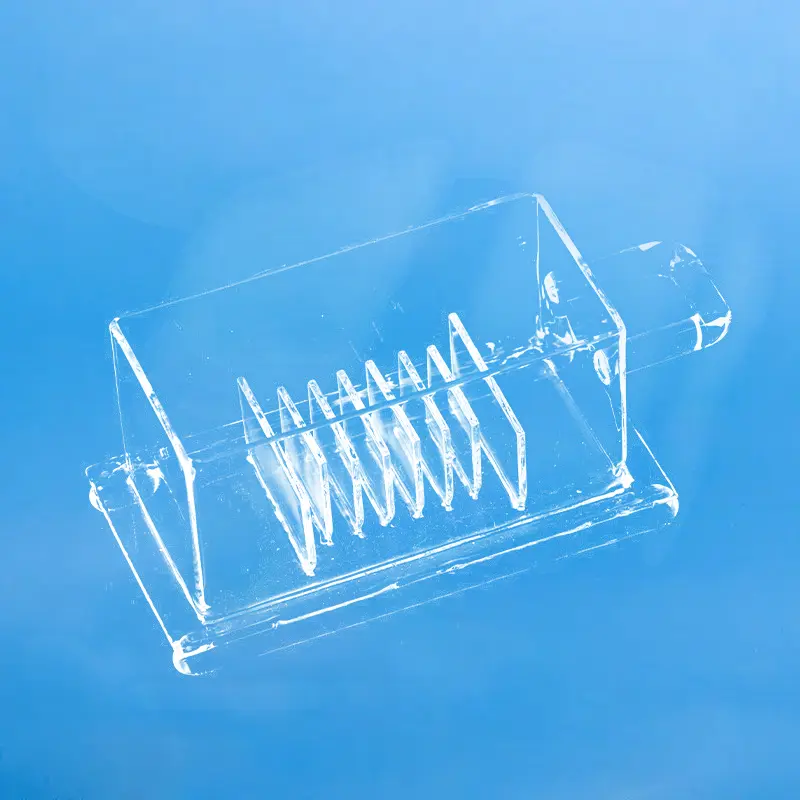

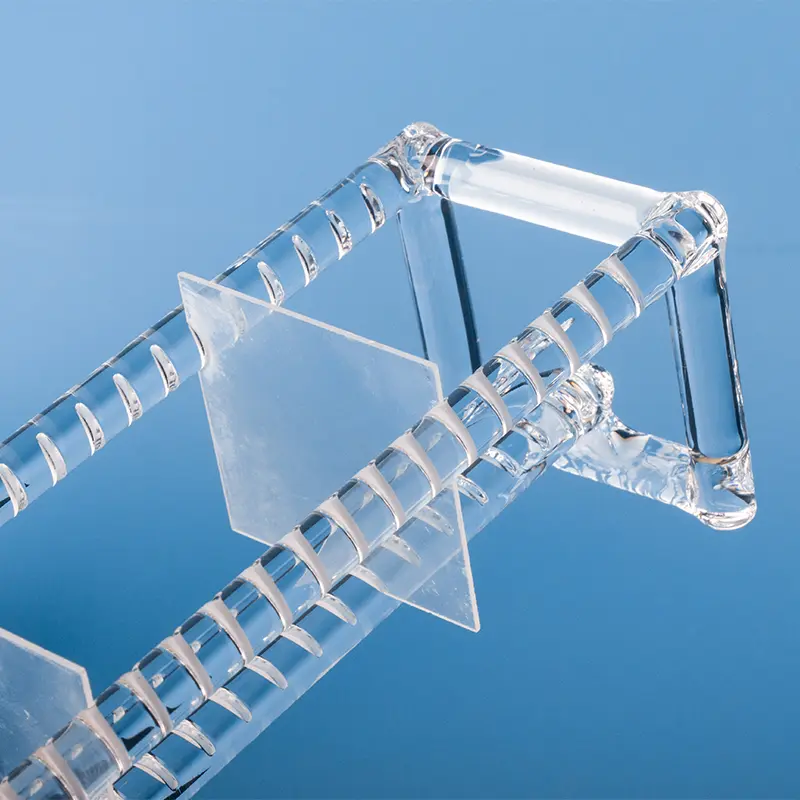

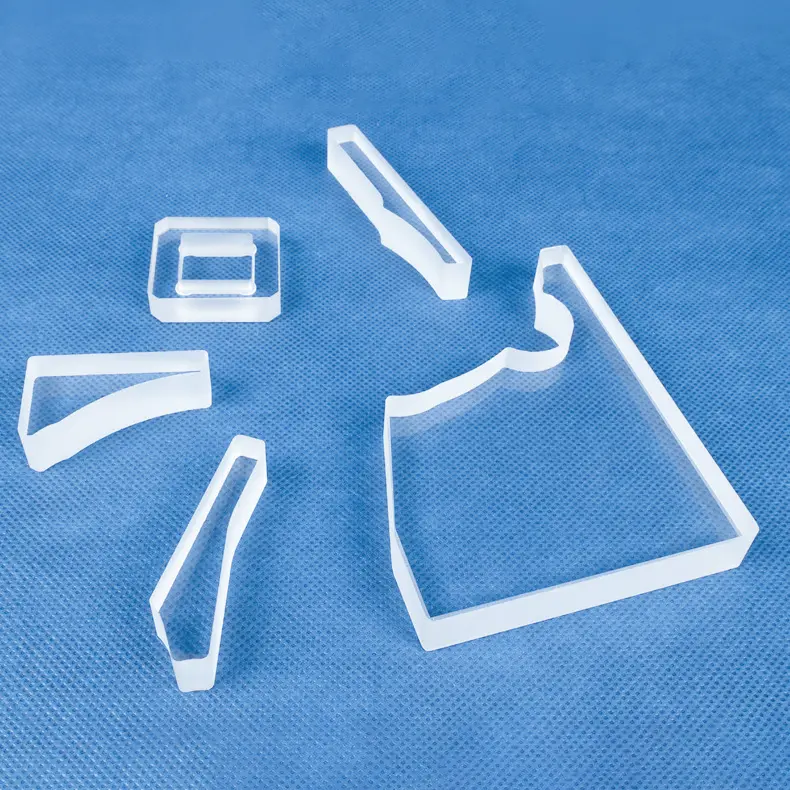

Nuestros burbujeadores de cuarzo a medida y recipientes de suministro de gas de alta pureza son componentes de sílice fundida mecanizados con precisión para aplicaciones críticas. Ideales para el suministro de precursores CVD/MOCVD, el procesamiento de semiconductores y el manejo de químicos corrosivos/de alta temperatura, aseguran un control preciso de fluidos/gases. Su pureza excepcional y estabilidad térmica satisfacen las demandas industriales y de investigación más exigentes.

| Contenido de la propiedad | Valores de la propiedad |

|---|---|

| SiO2 | 99.99% |

| Densidad | 2,2×10³ kg/cm³ |

| Dureza | Dureza Mohs de 5,5 a 6,5; Dureza Knoop 570 (con una carga de 100g) |

| Resistencia a la tracción | 4,8 × 10⁷ Pa (48 N/mm² o 48 MPa); 7.000 psi |

| Resistencia a la compresión | >1.1×10⁹ Pa (160,000 psi) |

| Coeficiente de dilatación térmica | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| Conductividad térmica | 1,4 W/m-°C |

| Calor específico | 670 J/kg-°C |

| Punto de ablandamiento | 1730°C (3146°F) |

| Punto de recocido | 1210°C (2210°F) |

| Punto de deformación | 1120°C (2048°F) |

| Temperatura de trabajo | 1200°C (2192°F) |

| Resistividad eléctrica | 7×10⁷ ohm cm (350°C) |

| Tamaño | Personalizado |

| Logotipo | Se acepta el logotipo personalizado |

Alta pureza

Las botellas fuente de cuarzo se fabrican con vidrio de cuarzo de alta pureza, lo que asegura la estabilidad química y la pureza del recipiente, previniendo así cualquier reacción o contaminación de los materiales almacenados.

Alta resistencia a la temperatura

El vidrio de cuarzo posee una excelente resistencia a altas temperaturas, lo que permite su uso a largo plazo a temperaturas elevadas sin deformación ni daño.

Resistencia a la corrosión

El vidrio de cuarzo demuestra una buena resistencia a la corrosión frente a una amplia variedad de reactivos químicos, lo que lo hace adecuado para el almacenamiento y transporte de diversas sustancias corrosivas.

Fácil limpieza

La superficie lisa del vidrio de cuarzo evita la adherencia de suciedad, lo que facilita una limpieza y un mantenimiento sencillos.

Escenario de aplicación

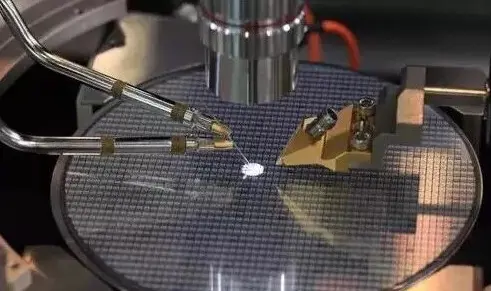

Industria de semiconductores

Producción de materiales y dispositivos semiconductores: Las botellas fuente de cuarzo son materiales indispensables en la producción de semiconductores, utilizados frecuentemente en crisoles, barcos (portadores de oblea), tubos centrales de horno y campanas de vacío para el crecimiento de monocristales de germanio y silicio. Estos componentes necesitan soportar altas temperaturas y entornos corrosivos, lo que hace que la resistencia a altas temperaturas y a la corrosión de las botellas fuente de cuarzo sea ideal.

Limpieza y difusión: En los procesos de limpieza y difusión de semiconductores, las botellas fuente de cuarzo también se utilizan comúnmente como tanques de limpieza y tubos de difusión para garantizar la estabilidad y precisión del proceso.

Tecnología óptica

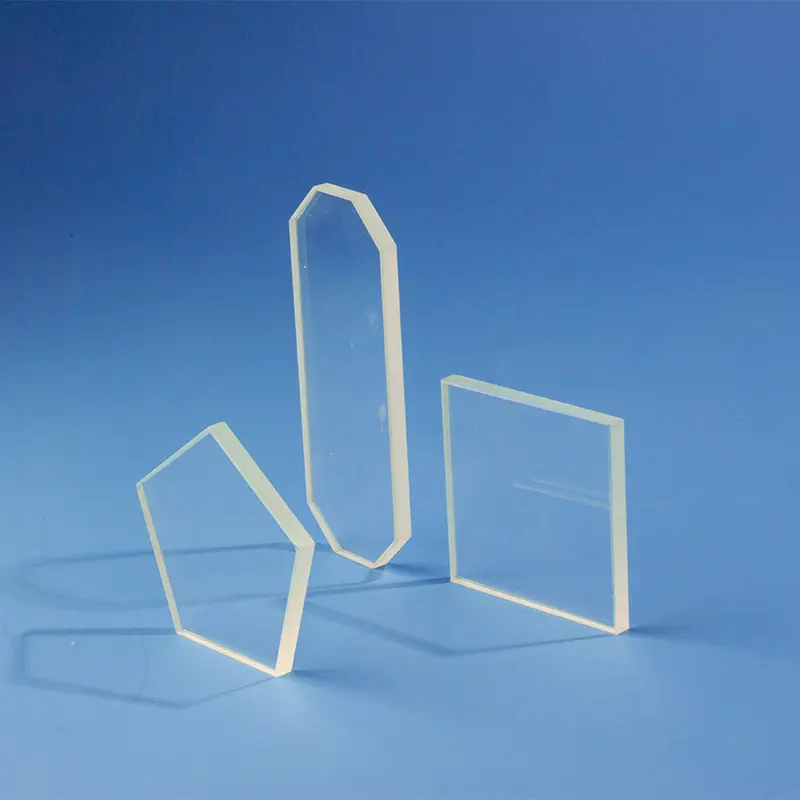

Instrumentos y equipos ópticos: Debido a sus excelentes propiedades ópticas, las botellas fuente de cuarzo se utilizan ampliamente en la fabricación de prismas y lentes para instrumentos ópticos como líneas de retardo ultrasónicas en radares, equipos de seguimiento y telémetros infrarrojos, cámaras infrarrojas, dispositivos de comunicación, espectrógrafos y espectrofotómetros.

Grandes telescopios astronómicos: El vidrio de cuarzo, debido a su alta transparencia y bajo coeficiente de expansión térmica, también se utiliza en la fabricación de ventanas reflectantes para grandes telescopios astronómicos con el fin de mejorar la precisión de observación y la estabilidad del telescopio.

Laboratorio e investigación

Recipientes de laboratorio: Debido a su estabilidad química y resistencia a altas temperaturas, las botellas fuente de cuarzo se utilizan a menudo como recipientes de laboratorio, por ejemplo, para la recolección y el procesamiento de residuos químicos.

Equipo de investigación: En entornos de investigación, las botellas fuente de cuarzo también se utilizan para fabricar diversos componentes de precisión para equipos de investigación, con el fin de satisfacer las necesidades de los estudios científicos.

Las botellas fuente de cuarzo tienen un contenido de dióxido de silicio (SiO2) de hasta 99,995 %, lo que elimina los riesgos asociados con la inhomogeneidad del vidrio (incluida la estratificación) y la lixiviación de iones metálicos problemáticos.

Quartz source bottles exhibit extremely high stability at high temperatures and do not easily deform. Their low thermal expansion coefficient and excellent thermal shock resistance allow them to maintain their shape and structural integrity under drastic temperature changes.

Garantizar la precisión experimental: Las botellas fuente de cuarzo pueden permanecer estables a temperaturas de hasta 1100 °C. Esto significa que, en experimentos de alta temperatura, las botellas fuente de cuarzo sirven como recipientes fiables, asegurando que la precisión de los resultados experimentales no se vea comprometida por la deformación térmica o la descomposición del recipiente.

Mejorar la seguridad experimental Las botellas fuente de cuarzo poseen una excelente resistencia al choque térmico, lo que significa que no son propensas a agrietarse incluso bajo cambios rápidos de temperatura. Esto reduce significativamente los riesgos de seguridad en experimentos de alta temperatura, protegiendo al personal de laboratorio y al equipo.

Preguntas más frecuentes

Nos especializamos en la fabricación integral de componentes de vidrio de cuarzo de alta pureza. Nuestras principales líneas de productos incluyen:

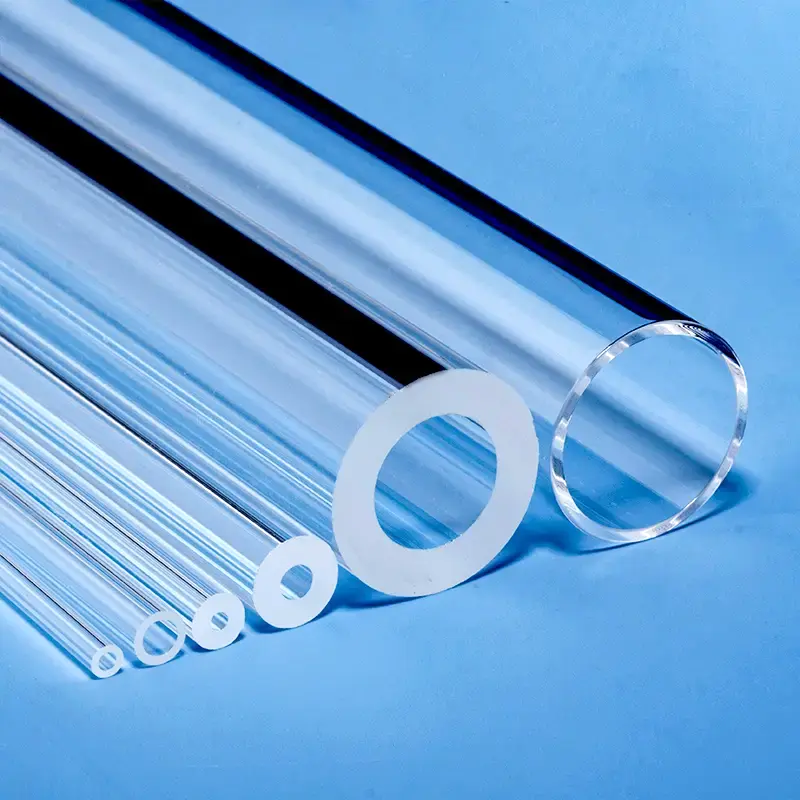

Tubos y varillas de cuarzo: Una amplia gama de diámetros y especificaciones.

Placas y discos de cuarzo: Corte de precisión y pulido para uso óptico e industrial.

Cristalería de laboratorio de cuarzo: Una suite completa de cristalería estándar y personalizada, incluyendo vasos de precipitados, matraces y barcas.

Cuarzo de grado semiconductor: Componentes de alta pureza como tubos de proceso y portadores para la fabricación de semiconductores.

Componentes fabricados a medida: Podemos producir piezas complejas adaptadas a sus diseños y especificaciones únicas.

Sí. La fabricación personalizada es el pilar central de nuestro negocio. Con más de una década de experiencia especializada, nos asociamos con empresas para ofrecerles servicios expertos de OEM/ODM. Nuestras capacidades incluyen soldadura, rectificado, perforación, pulido, doblado y otras técnicas de mecanizado de precisión para crear componentes que cumplan con sus requisitos exactos.

La calidad es primordial en nuestro proceso de fabricación. Somos un fabricante certificado ISO 9001:2015, lo que garantiza que nuestros procesos cumplen con los estándares internacionales de gestión de calidad.Nuestros productos también se someten a rigurosas pruebas SGS de pureza y rendimiento. Utilizamos materias primas de alta pureza (hasta 99,998% de SiO2) para producir productos de cuarzo fundido y sílice fundida con una estabilidad térmica excepcional, alta resistencia a la temperatura e inercia química.

Hemos optimizado nuestro proceso para que sea lo más eficiente posible:

Envíe su Solicitud de Cotización (RFQ): Envíenos sus dibujos técnicos, especificaciones y requisitos a través de nuestro formulario de contacto en el sitio web o por correo electrónico.

Respuesta rápida: Puede esperar una respuesta inicial en cuestión de minutos y una comunicación detallada en media hora.

Diseño y Propuesta: Le entregaremos una propuesta de diseño detallada y un presupuesto competitivo en 24 horas.

Prototipado y Producción: Tras la aprobación, pasamos rápidamente del prototipado a la producción a gran escala para cumplir con sus plazos de entrega.

Asociarse con Aoxin Quartz ofrece varias ventajas clave:

Experiencia comprobada: Con más de 10 años en la industria, poseemos el conocimiento técnico para abordar desafíos complejos.

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

Valor competitivo: Ubicados en un importante centro de producción de cuarzo, aprovechamos una cadena de suministro eficiente y una fabricación avanzada para ofrecer una calidad excepcional a un precio competitivo.

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.