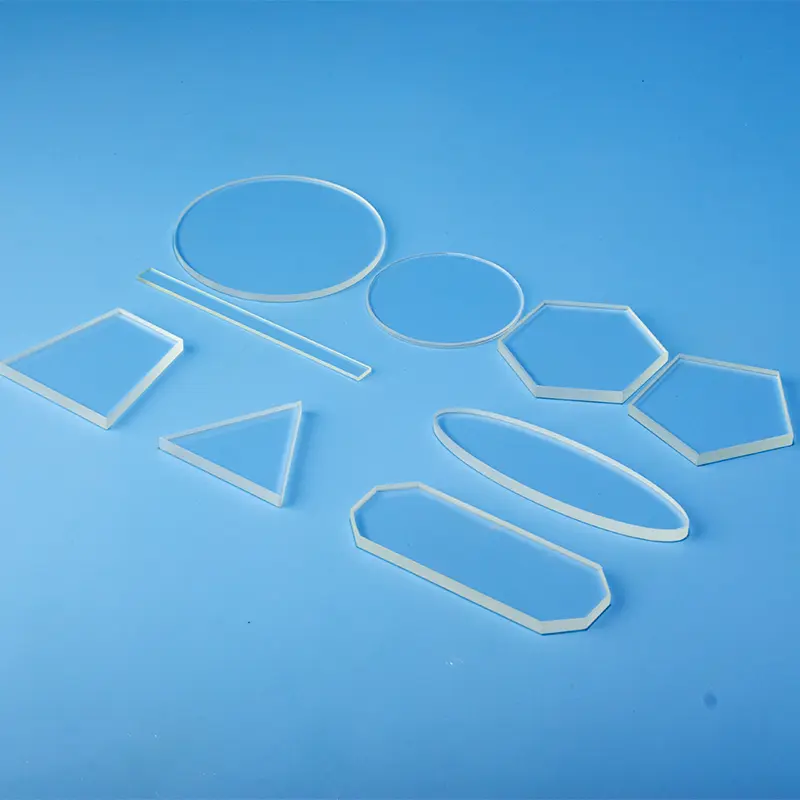

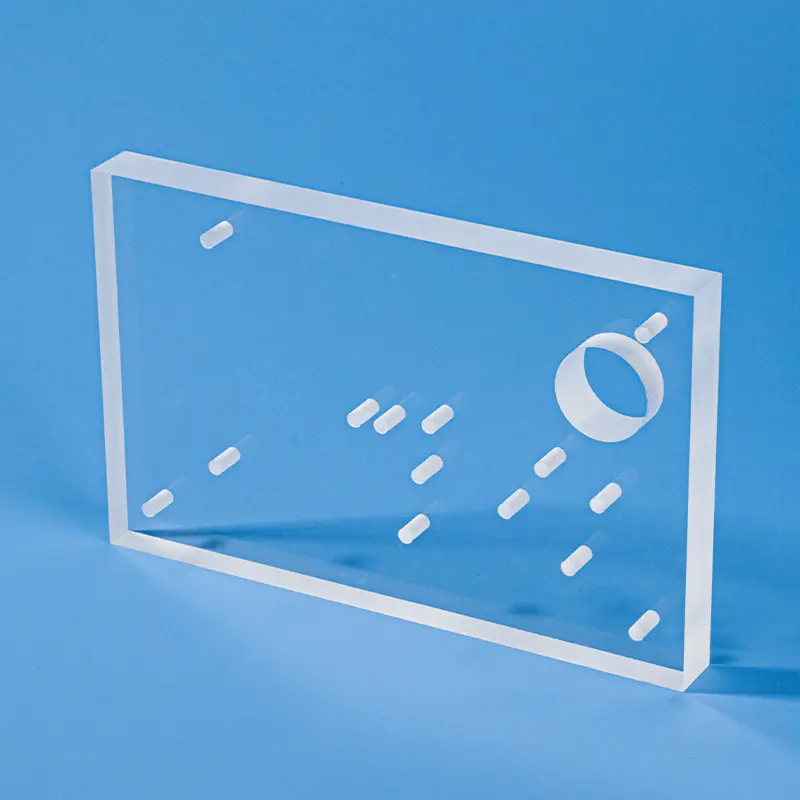

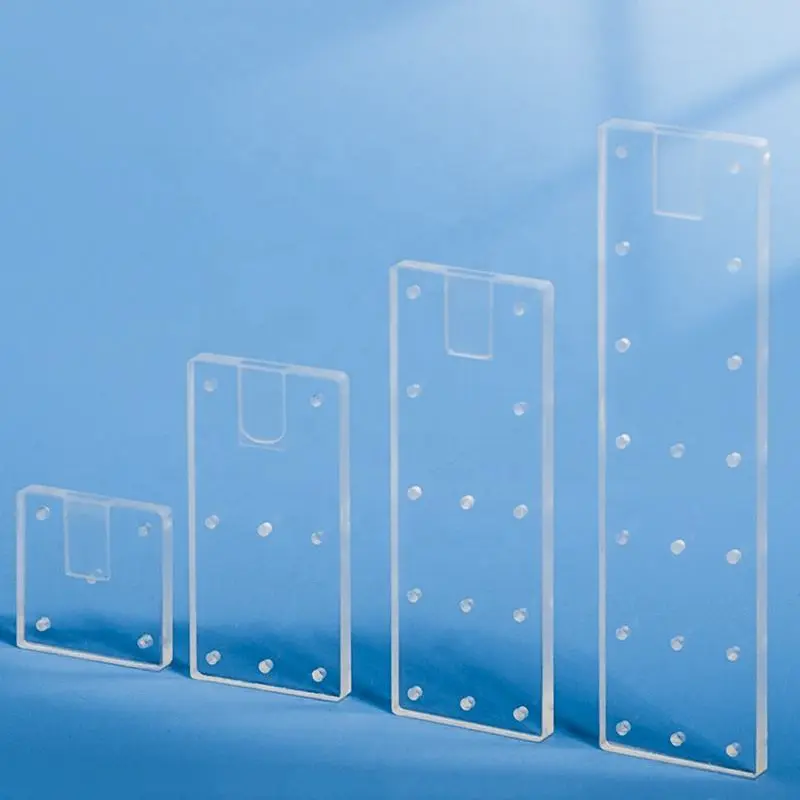

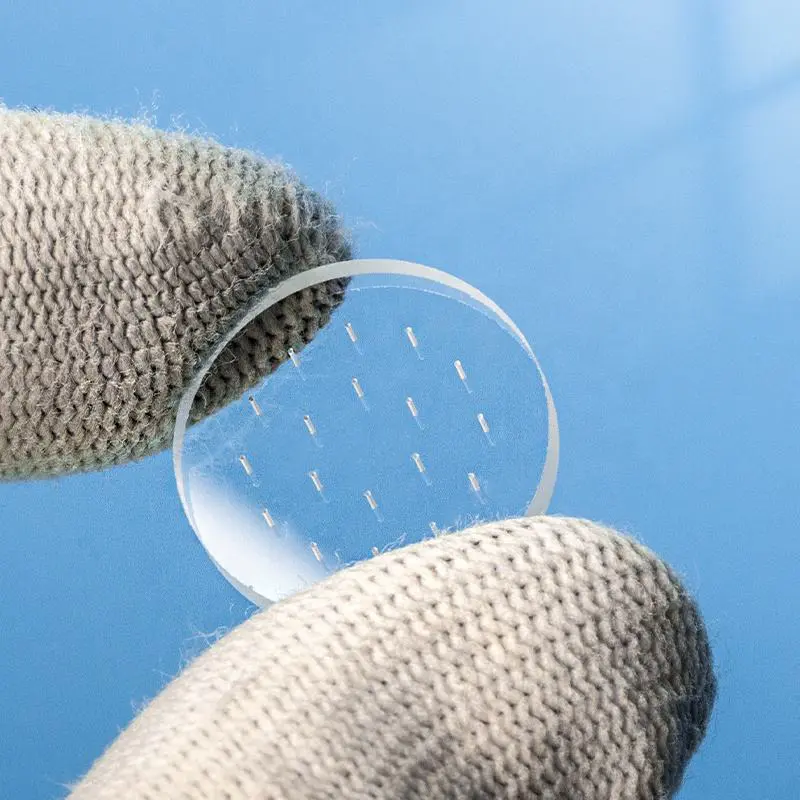

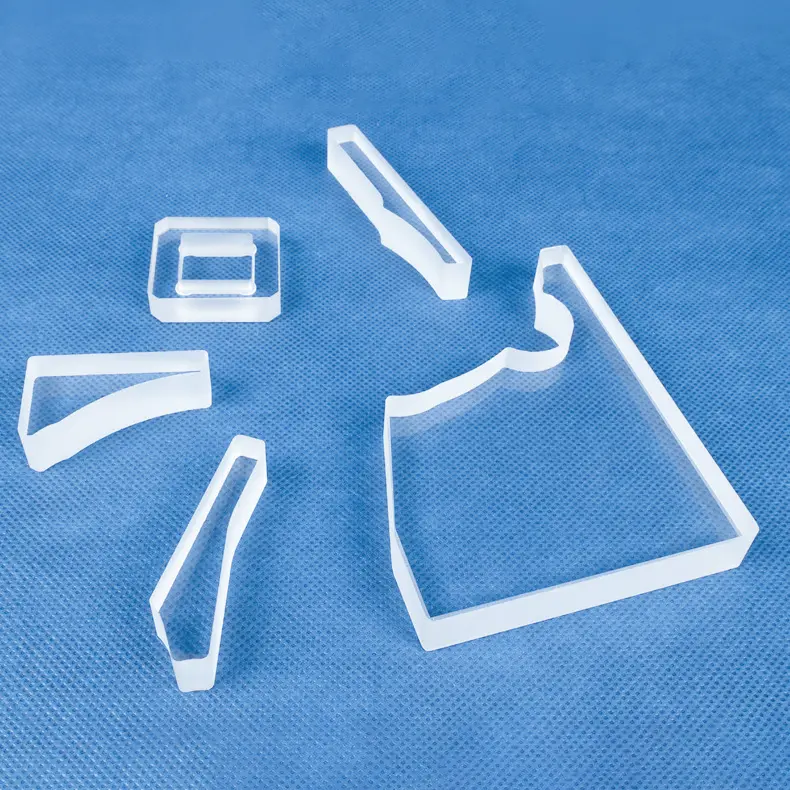

Nuestras ventanas de cuarzo son componentes de ingeniería de precisión elaborados a partir de sílice fundida de alta pureza, diseñadas específicamente para la observación e inspección críticas en entornos desafiantes. Estas ventanas de alto rendimiento ofrecen una excelente transmisión de luz en todo el espectro (superando el 93% en el rango visible), una resistencia superior a altas temperaturas y productos químicos corrosivos, y un robusto aislamiento eléctrico. Ideales para cámaras de vacío, hornos, instrumentos científicos y procesos industriales donde una visualización clara y duradera es esencial, nuestras mirillas de cuarzo garantizan un rendimiento fiable en condiciones extremas.

- Método de pago: Mediante transferencia bancaria o pago por adelantado, dependiendo de la cantidad del pedido

- Plazo de entrega: Según la cantidad del pedido

- Método de transporte: Flete marítimo o flete aéreo, según el cliente.

Observaciones:

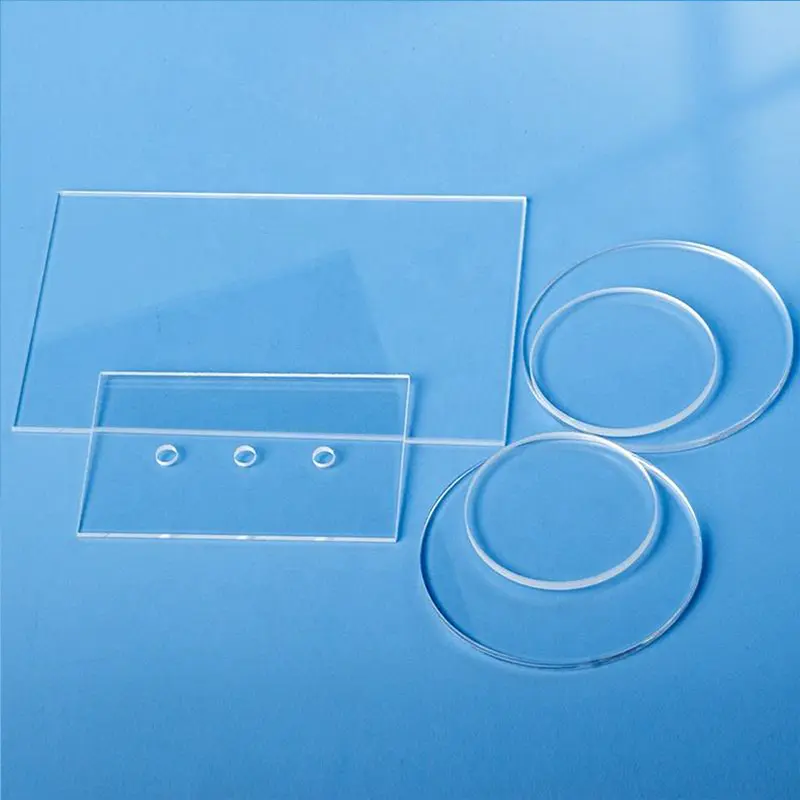

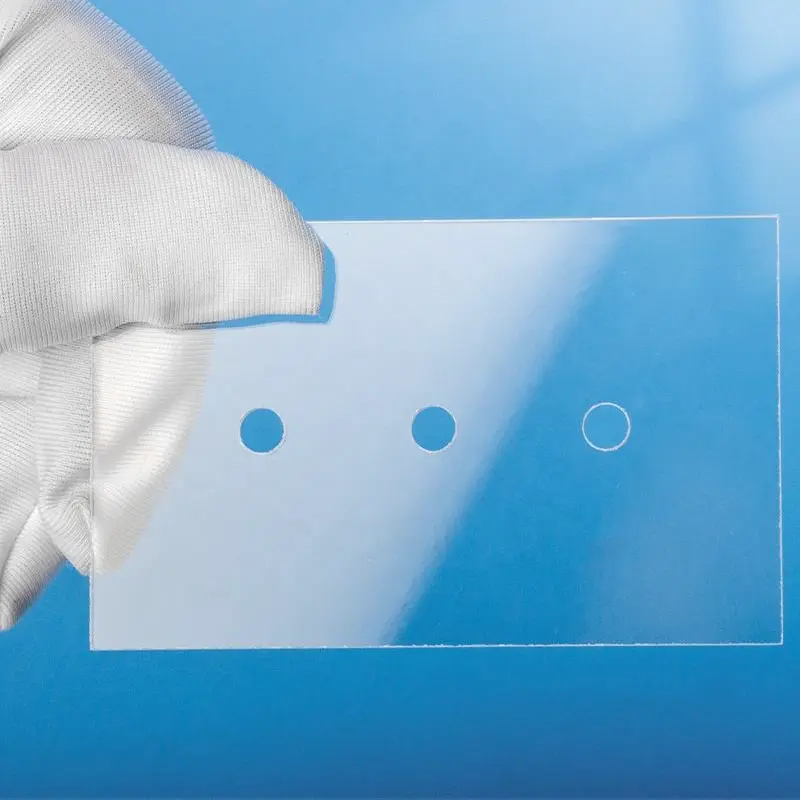

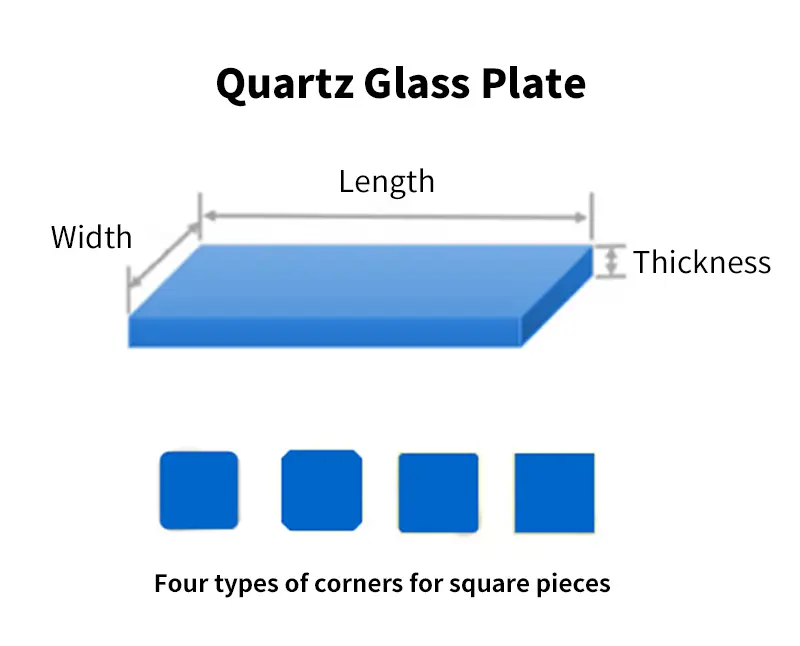

Para confirmar el pedido, deben proporcionarse los siguientes parámetros: ① Cuadrado: longitud, ancho, grosor ② Círculo: diámetro, grosor ③ Precisión ④ Cantidad

| Contenido de la propiedad | Valores de la propiedad |

|---|---|

| SiO2 | 99.99% |

| Densidad | 2,2×10³ kg/cm³ |

| Dureza | Dureza Mohs de 5,5 a 6,5; Dureza Knoop 570 (con una carga de 100g) |

| Resistencia a la tracción | 4,8 × 10⁷ Pa (48 N/mm² o 48 MPa); 7.000 psi |

| Resistencia a la compresión | >1.1×10⁹ Pa (160,000 psi) |

| Coeficiente de dilatación térmica | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| Conductividad térmica | 1,4 W/m-°C |

| Calor específico | 670 J/kg-°C |

| Punto de ablandamiento | 1730°C (3146°F) |

| Punto de recocido | 1210°C (2210°F) |

| Punto de deformación | 1120°C (2048°F) |

| Temperatura de trabajo | 1200°C (2192°F) |

| Resistividad eléctrica | 7×10⁷ ohm cm (350°C) |

| Tamaño | Personalizado |

| Logotipo | Se acepta el logotipo personalizado |

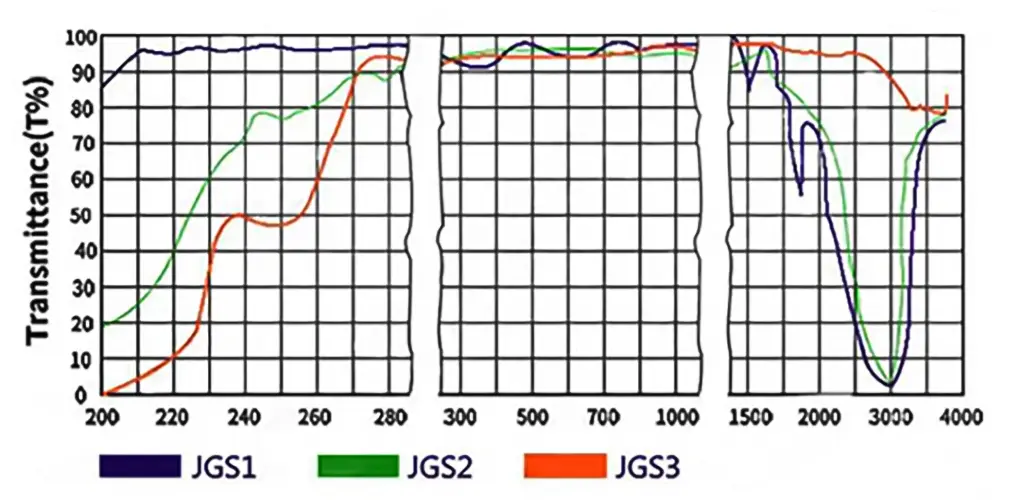

JGS1

Conocido comúnmente como sílice fundida de grado UV, este material exhibe una dispersión excepcionalmente baja y una muy alta transmitancia en el rango espectral ultravioleta (UV)

JGS2

Similar al JGS1, pero puede presentar variaciones en parámetros de rendimiento específicos, como la transmitancia y el coeficiente de expansión térmica, dependiendo de los estándares del fabricante.

JGS3

Se utiliza típicamente en aplicaciones que requieren una mayor pureza o características de rendimiento especializadas. Los parámetros de rendimiento específicos pueden variar según el fabricante.

Alta resistencia a la temperatura

El vidrio de cuarzo, como material principal para estas ventanas de visión, exhibe una resistencia extremadamente alta a la temperatura. Su punto de ablandamiento alcanza aproximadamente 1730 °C y se puede utilizar de forma continua a 1100 °C, con un uso a corto plazo de hasta 1450 °C. Esto permite que las ventanas de visión de cuarzo a alta temperatura soporten diversos entornos de alta temperatura sin deformarse ni fracturarse.

Alta transmisión de luz

El vidrio de cuarzo tiene típicamente una transmitancia luminosa superior al 90%, con una transmitancia que supera el 93% en el rango de luz visible y una alta transmitancia en el rango espectral UV. Esta alta transmisión de luz permite que las ventanas de cuarzo de alta temperatura proporcionen una vista clara de los procesos de producción dentro de equipos de alta temperatura.

Estabilidad química

El vidrio de cuarzo posee una excelente estabilidad química, con casi ninguna reacción a otros ácidos, y una resistencia al ácido que es 30 veces mayor que la de la cerámica y 150 veces mayor que la del acero inoxidable. Esto permite que las ventanas de visualización de cuarzo a altas temperaturas funcionen de manera fiable durante largos períodos en entornos corrosivos, como ácidos y álcalis.

Bajo coeficiente de expansión térmica

El vidrio de cuarzo tiene un coeficiente de expansión térmica muy bajo y puede resistir cambios de temperatura repentinos. Incluso cuando se calienta a aproximadamente 1100 °C y luego se coloca rápidamente en agua a temperatura ambiente, no se fracturará.

Escenario de aplicación

Las ventanas de cuarzo tienen una buena transmisión de luz a través de todo el espectro, desde el ultravioleta hasta el infrarrojo, con una transmitancia de luz visible que supera el 93%. En el rango espectral ultravioleta, la transmitancia puede alcanzar más del 80%.

Las ventanas de cuarzo exhiben una alta resistencia dieléctrica y una muy baja conductividad eléctrica (pérdida dieléctrica baja). Incluso a altas temperaturas, su conductividad eléctrica y pérdida dieléctrica permanecen por debajo de las de muchos otros materiales, lo que las hace adecuadas como materiales de aislamiento de alta frecuencia y voltaje en condiciones de alta temperatura y tensión mecánica.

Las ventanas de cuarzo poseen una excelente estabilidad química y, con la excepción del ácido fluorhídrico, casi no muestran reacciones químicas con otros ácidos, y tienen una excelente resistencia a la corrosión.

Preguntas más frecuentes

Nos especializamos en la fabricación integral de componentes de vidrio de cuarzo de alta pureza. Nuestras principales líneas de productos incluyen:

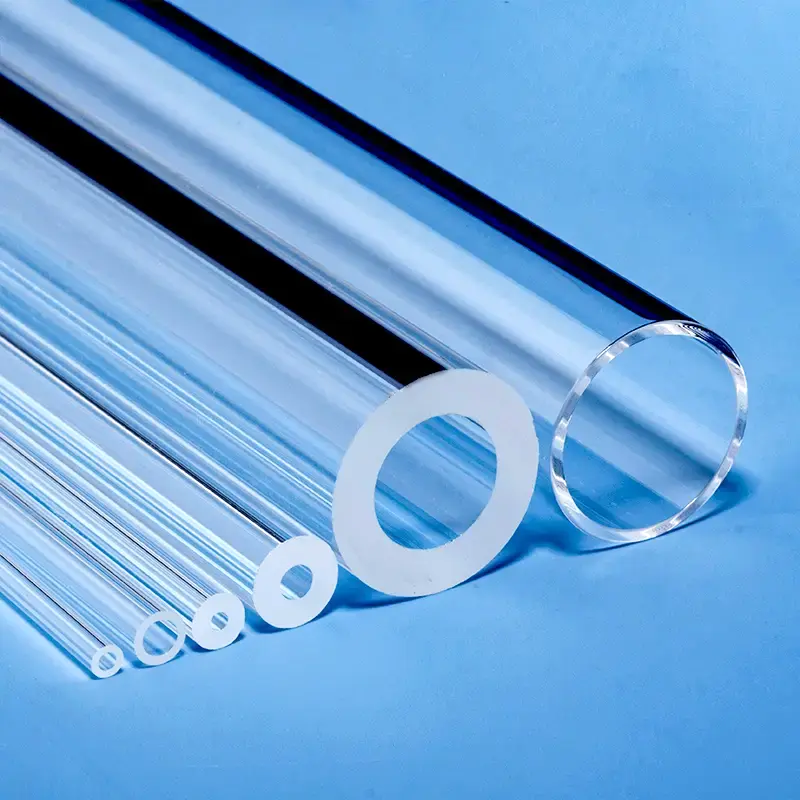

Tubos y varillas de cuarzo: Una amplia gama de diámetros y especificaciones.

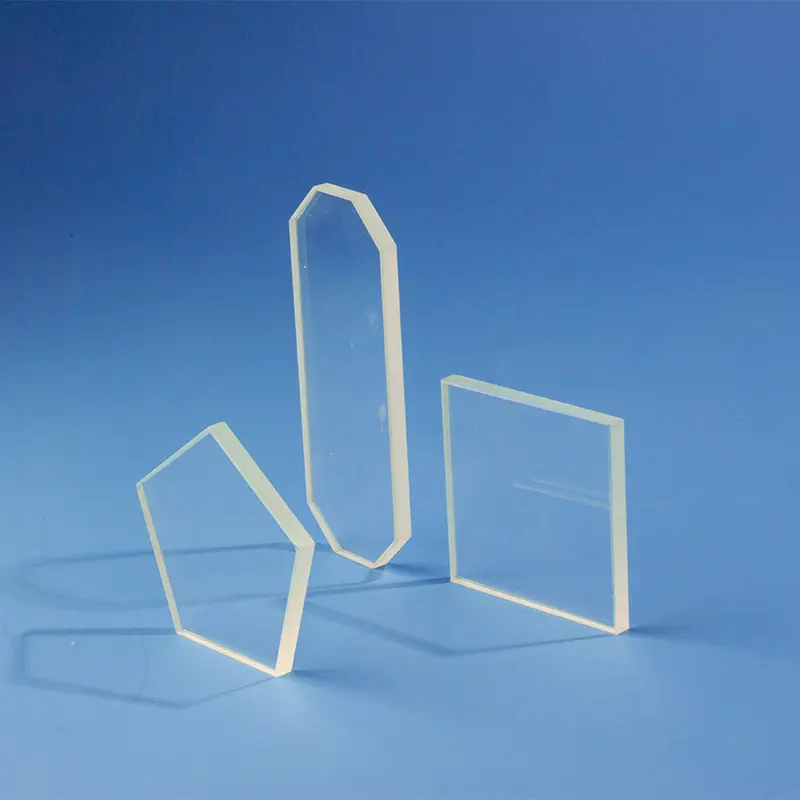

Placas y discos de cuarzo: Corte de precisión y pulido para uso óptico e industrial.

Cristalería de laboratorio de cuarzo: Una suite completa de cristalería estándar y personalizada, incluyendo vasos de precipitados, matraces y barcas.

Cuarzo de grado semiconductor: Componentes de alta pureza como tubos de proceso y portadores para la fabricación de semiconductores.

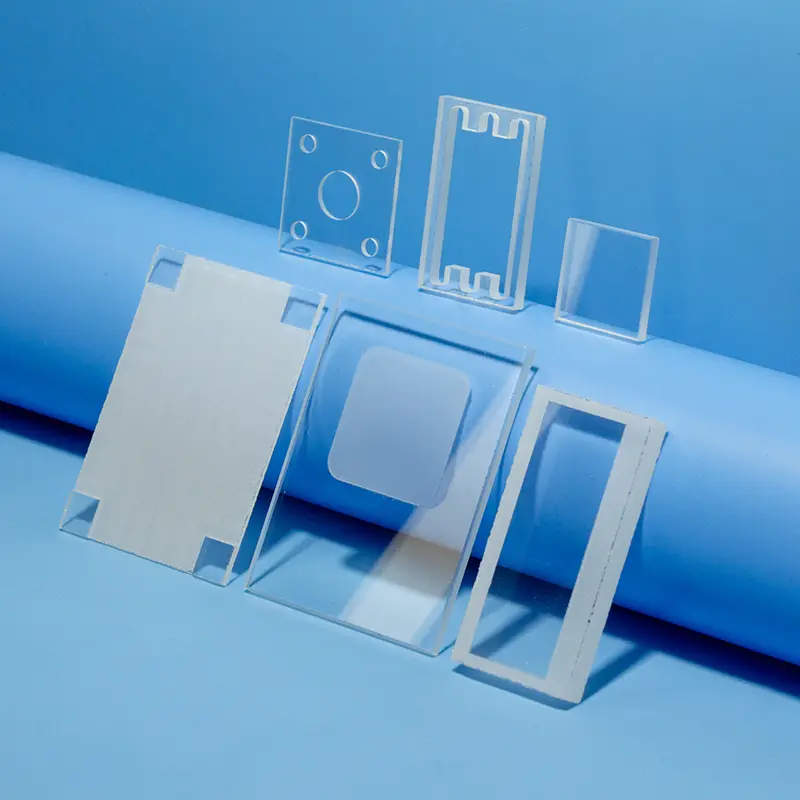

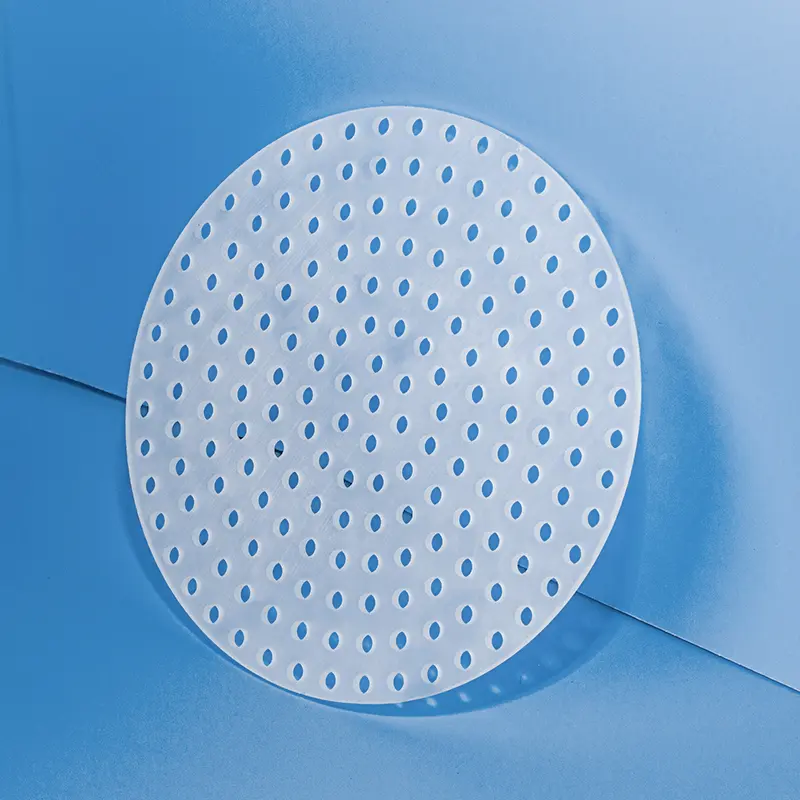

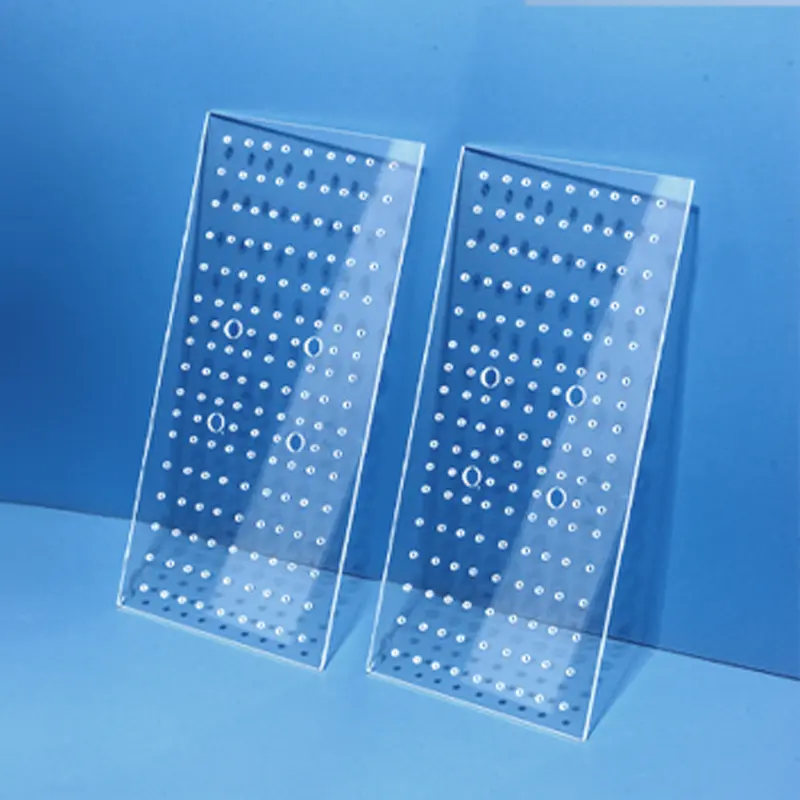

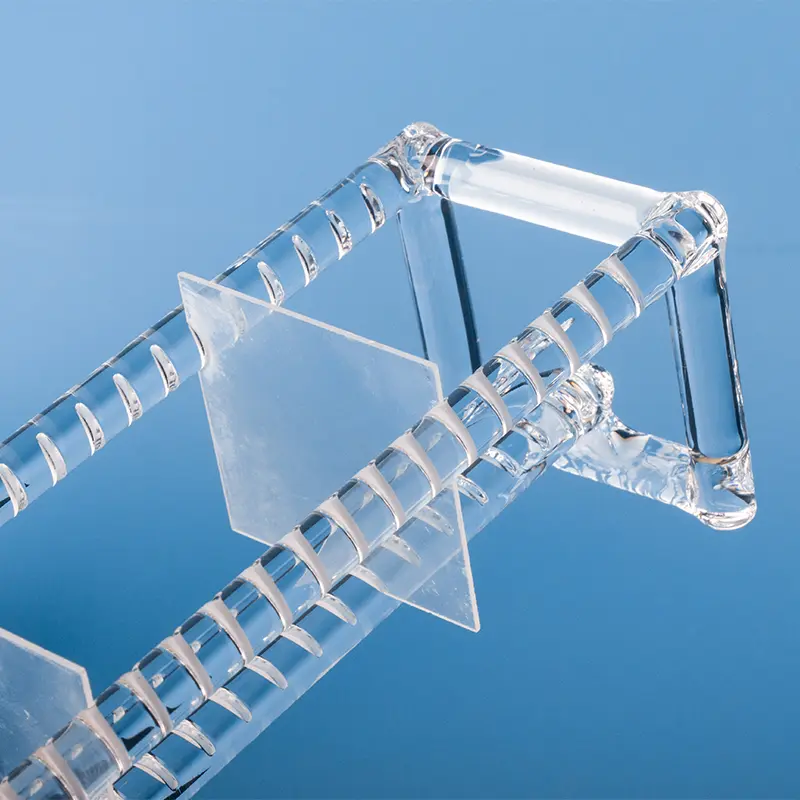

Componentes fabricados a medida: Podemos producir piezas complejas adaptadas a sus diseños y especificaciones únicas.

Sí. La fabricación personalizada es el pilar central de nuestro negocio. Con más de una década de experiencia especializada, nos asociamos con empresas para ofrecerles servicios expertos de OEM/ODM. Nuestras capacidades incluyen soldadura, rectificado, perforación, pulido, doblado y otras técnicas de mecanizado de precisión para crear componentes que cumplan con sus requisitos exactos.

La calidad es primordial en nuestro proceso de fabricación. Somos un fabricante certificado ISO 9001:2015, lo que garantiza que nuestros procesos cumplen con los estándares internacionales de gestión de calidad.Nuestros productos también se someten a rigurosas pruebas SGS de pureza y rendimiento. Utilizamos materias primas de alta pureza (hasta 99,998% de SiO2) para producir productos de cuarzo fundido y sílice fundida con una estabilidad térmica excepcional, alta resistencia a la temperatura e inercia química.

Hemos optimizado nuestro proceso para que sea lo más eficiente posible:

Envíe su Solicitud de Cotización (RFQ): Envíenos sus dibujos técnicos, especificaciones y requisitos a través de nuestro formulario de contacto en el sitio web o por correo electrónico.

Respuesta rápida: Puede esperar una respuesta inicial en cuestión de minutos y una comunicación detallada en media hora.

Diseño y Propuesta: Le entregaremos una propuesta de diseño detallada y un presupuesto competitivo en 24 horas.

Prototipado y Producción: Tras la aprobación, pasamos rápidamente del prototipado a la producción a gran escala para cumplir con sus plazos de entrega.

Asociarse con Aoxin Quartz ofrece varias ventajas clave:

Experiencia comprobada: Con más de 10 años en la industria, poseemos el conocimiento técnico para abordar desafíos complejos.

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

Valor competitivo: Ubicados en un importante centro de producción de cuarzo, aprovechamos una cadena de suministro eficiente y una fabricación avanzada para ofrecer una calidad excepcional a un precio competitivo.

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.