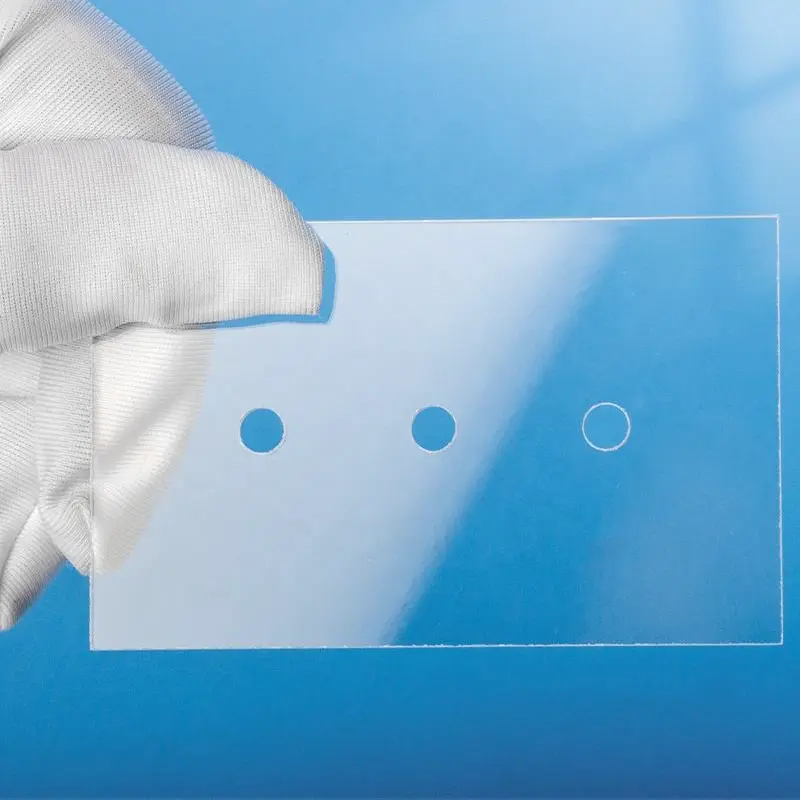

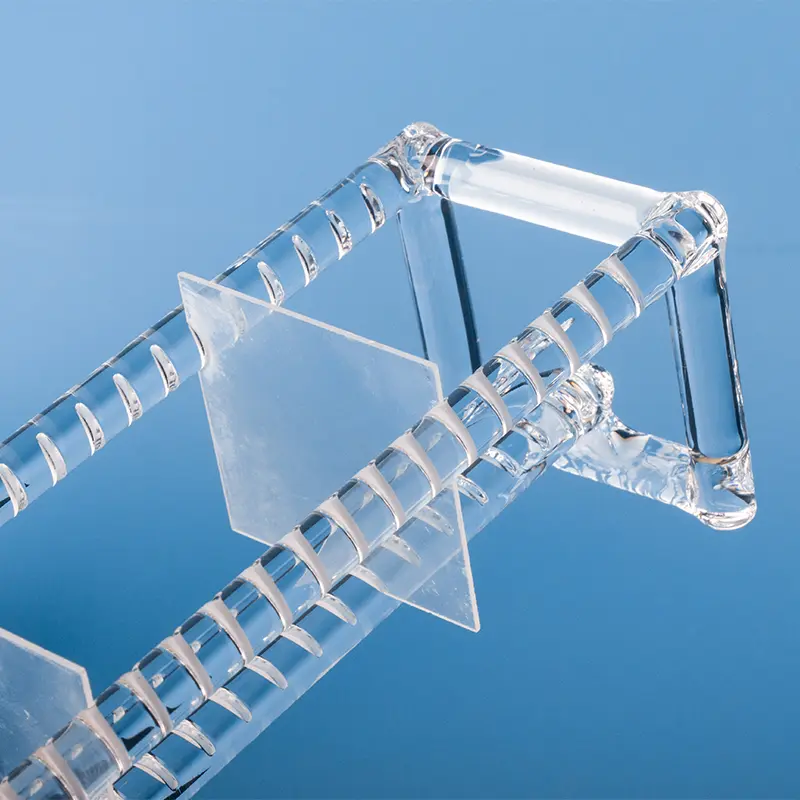

クォーツプレスバーは、電子機器の製造および修理に広く使用されている重要なコンポーネントであり、特にホットプレス装置やLCD業界で使用されています。

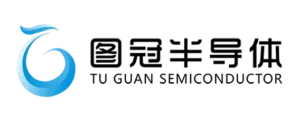

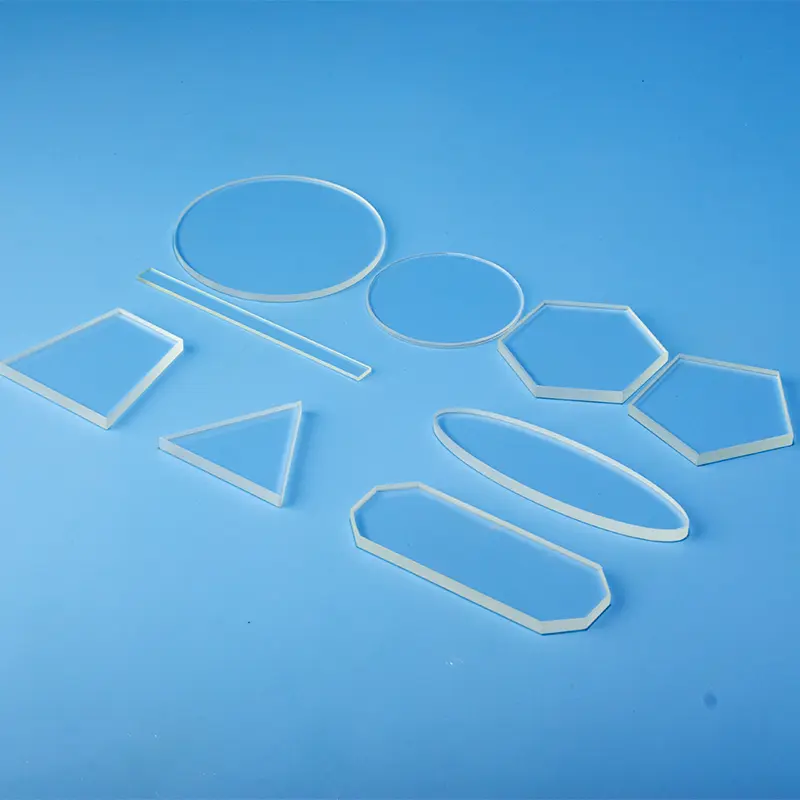

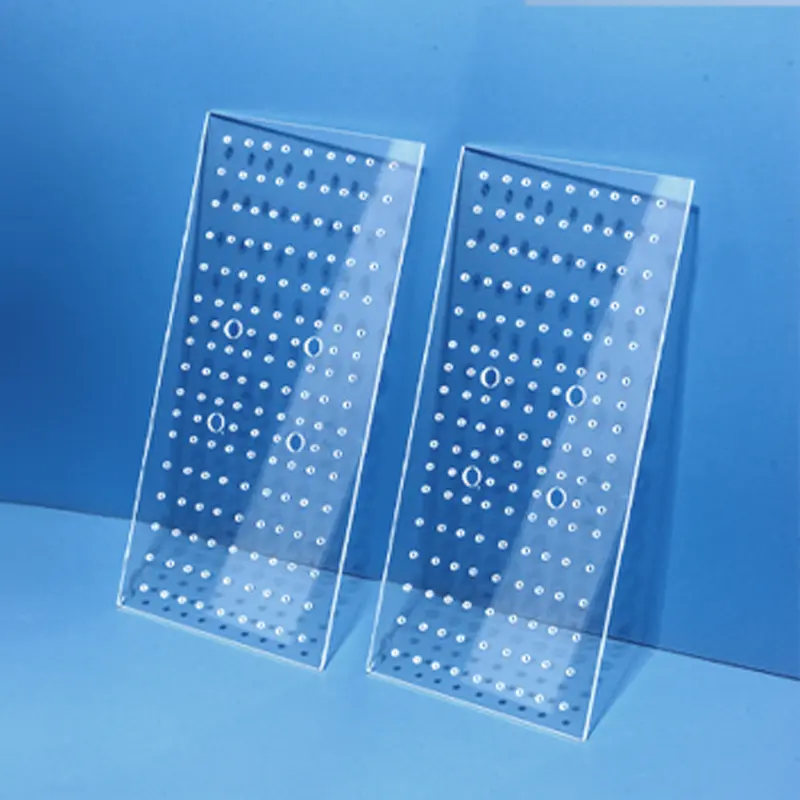

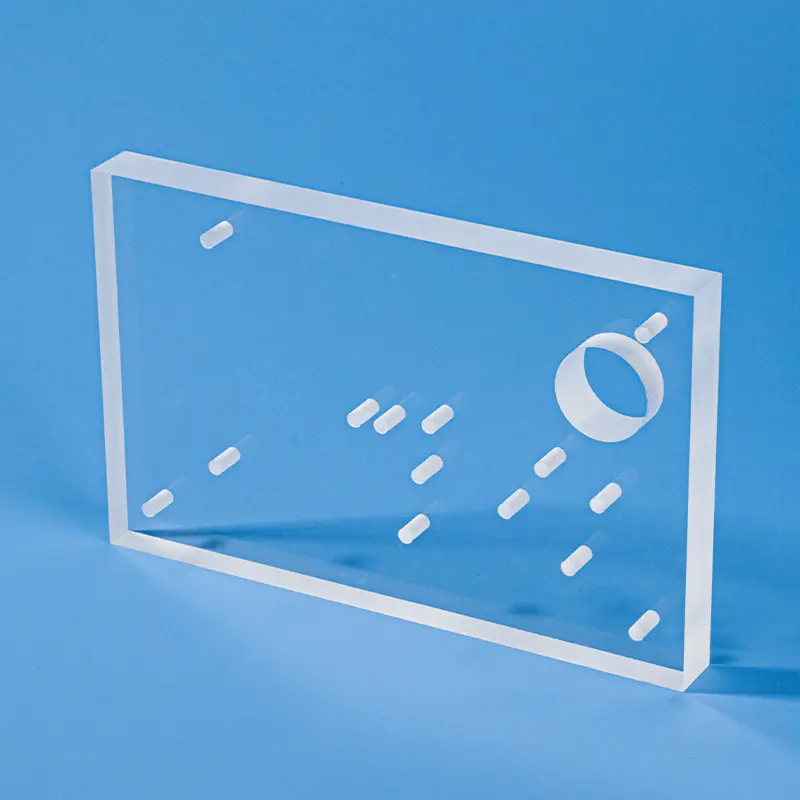

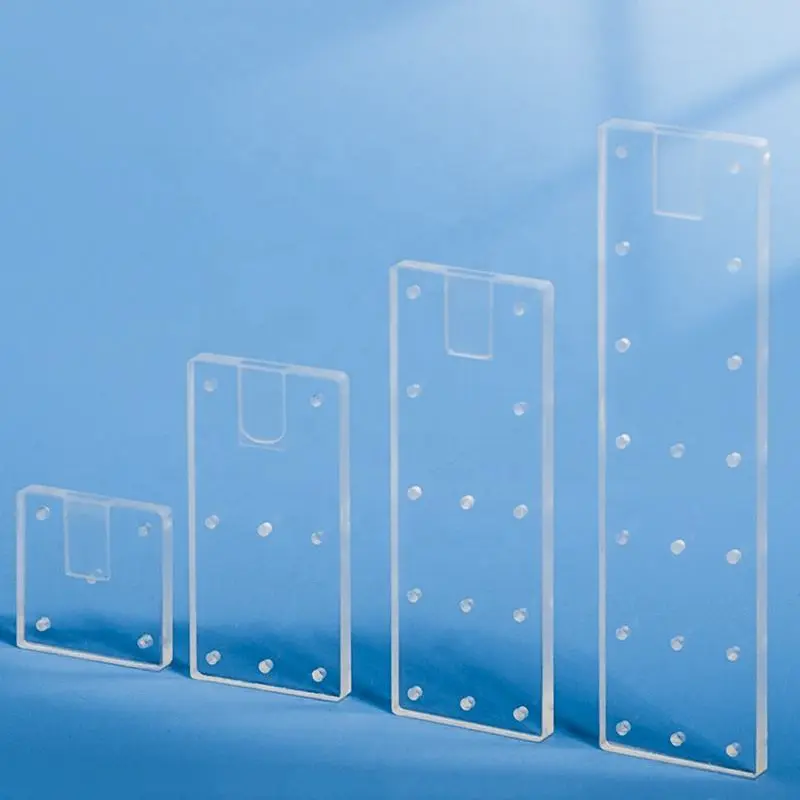

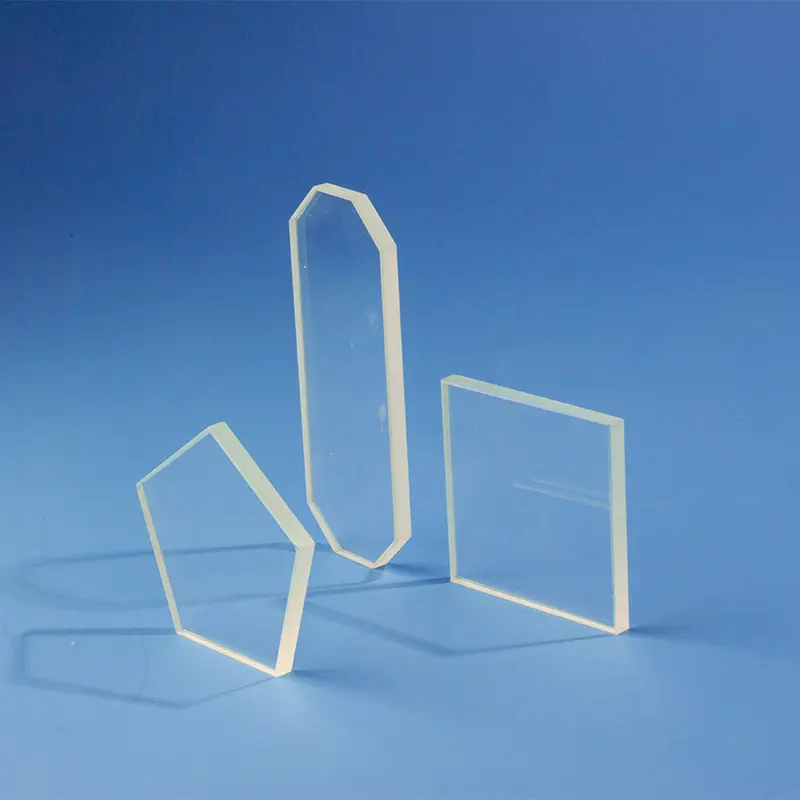

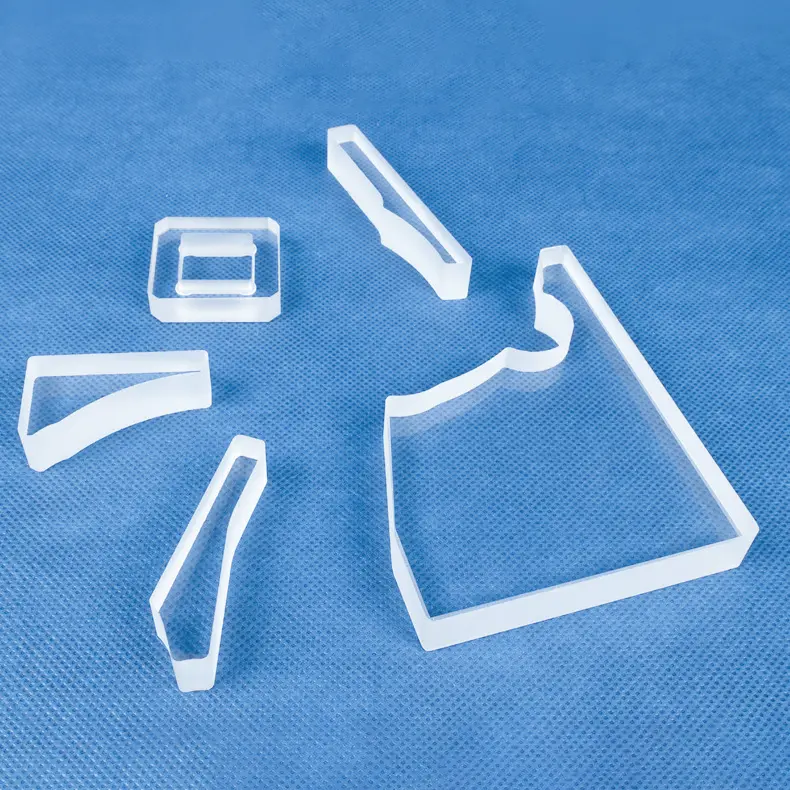

石英プレスバーは、お客様の特定の要件に合わせて、L型、T型、角棒、二段型などの様々な形状、寸法、および精度レベルで特注製造が可能です。専門メーカーは、高度な加工設備と豊富な製造経験を有しており、高品質かつ高精度の石英プレスバー製品をお客様に提供します

| 特性内容 | 特性値 |

|---|---|

| SiO2 | 99.99% |

| 密度 | 2.2×10³ kg/cm³ |

| 硬度 | モース硬度 5.5~6.5; ヌープ硬度 570 (荷重100g) |

| 引張強度 | 4.8 × 10⁷ Pa (48 N/mm² または 48 MPa); 7,000 psi |

| 圧縮強度 | >1.1×10⁹ Pa (160,000 psi) |

| 熱膨張係数 | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| 熱伝導率 | 1.4 W/m-°C |

| 比熱 | 670 J/kg-°C |

| 軟化点 | 1730度C(3146度F) |

| 徐冷点 | 1210度C(2210度F) |

| 歪点 | 1120度C(2048度F) |

| 使用温度 | 1200°C |

| 電気抵抗率 | 7×10⁷Ωcm (350°C) |

| サイズ | カスタマイズ対応 |

| ロゴ | ロゴのカスタマイズ対応 |

高光沢透過率

石英プレスバーは非常に高い光透過率を示し、通常は99%以上に達し、プレスプロセス中の効率的な光伝送を保証します。

優れた平坦性

その表面平坦度は極めて高く、しばしば±0.002mmを達成し、高精度なプレス加工を容易にします

高温および化学的耐性

石英材料は、高温および化学物質に対して優れた耐性を示し、過酷な作業環境下でも安定性を維持します

高硬度

石英は高い硬度を有しており、これによりプレスバーは使用中に優れた耐摩耗性と耐擦傷性を発揮します。

取り扱い注意

石英ガラス製品は貴重な材料であり、衝突や落下を避けるために注意して取り扱う必要があります。

温度制限

あらゆる種類の石英ガラスには、最高使用温度が設定されています。この温度を超過してはなりません。超過した場合、失透(結晶化)や軟化、変形を引き起こす可能性があります

清掃手順

高温使用向けの石英ガラス製品は、使用前に徹底的に清掃する必要があります。これは、適切な洗浄溶液に浸した後、高純度の水で rinsing するか、アルコールで処理することで達成できます。

熱衝撃を避ける

石英ガラスは優れた熱安定性を持っていますが、残留応力や製品形状の変化により、熱衝撃抵抗が異なることがあります。これらの違いは使用時に考慮する必要があります。

アルカリ性物質との接触を避けてください。

酸性材料である石英ガラスは、アルカリ性物質(例えば水ガラス、アスベスト、カリウムおよびナトリウム化合物)から遠ざけるべきであり、高温では接触があれば結晶化抵抗が大幅に低下します。

よくある質問

当社は、高純度石英ガラス部品の一貫製造を専門としております。主な製品ラインナップは以下の通りです:

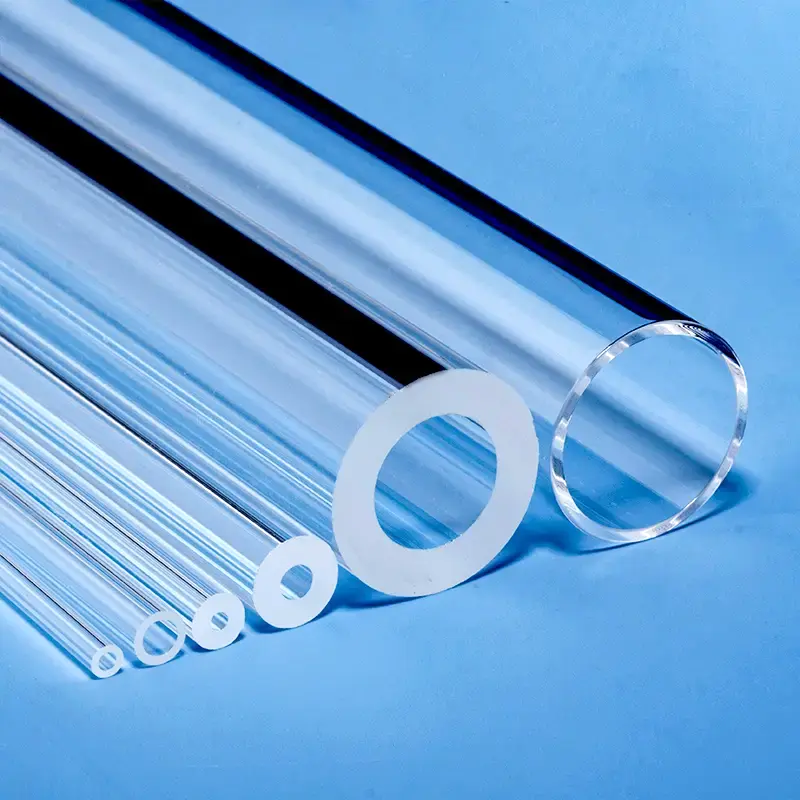

石英管・石英棒: 幅広い直径と仕様。

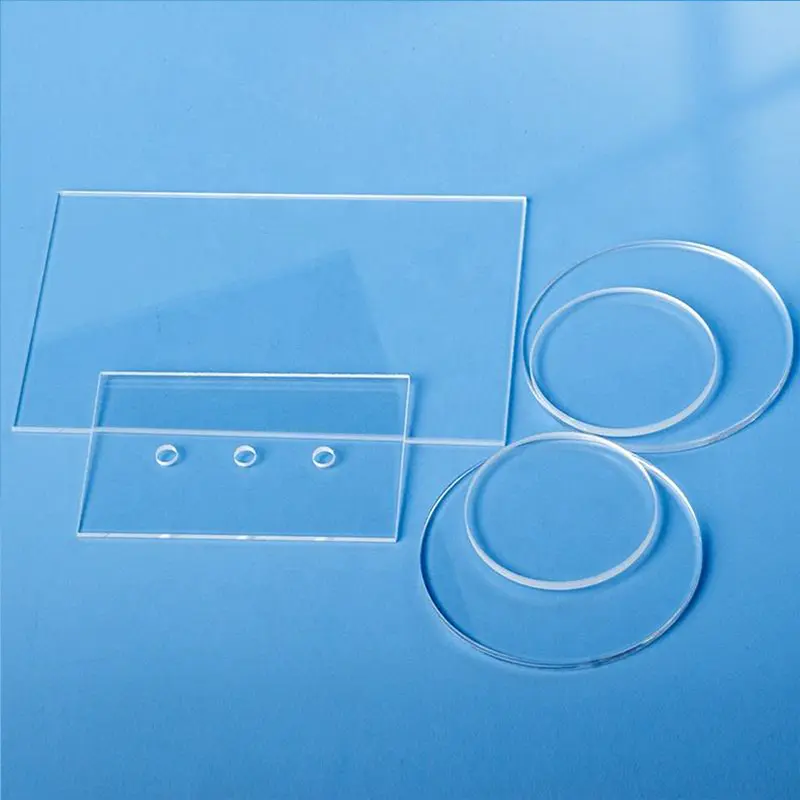

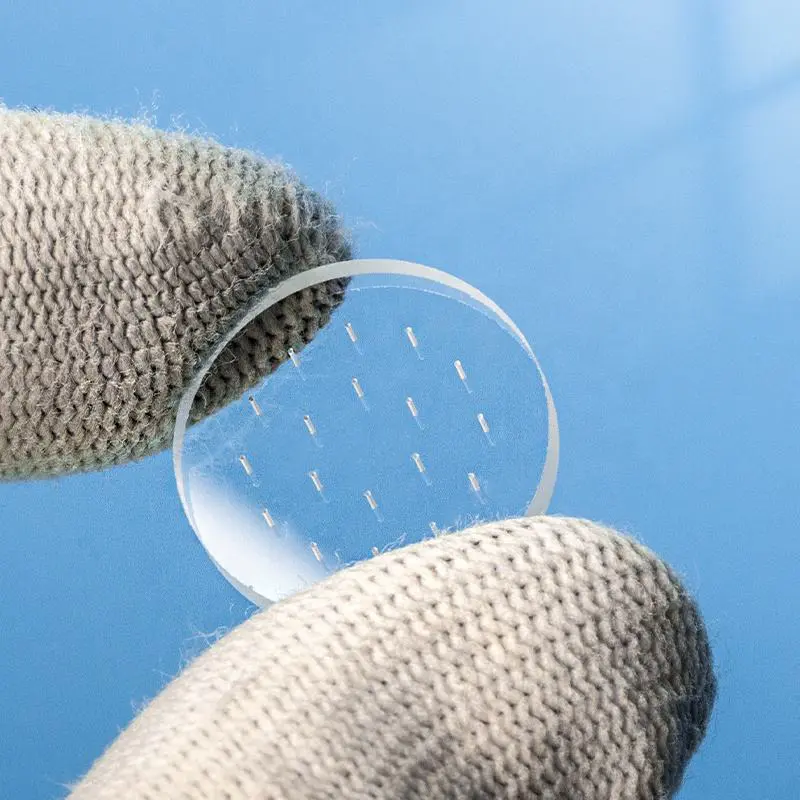

石英プレート・ディスク: 光学および工業用途向けに精密に切断・研磨。

石英実験器具: ビーカー、フラスコ、ボートなど、標準品から特注品まで幅広い種類のガラス器具。

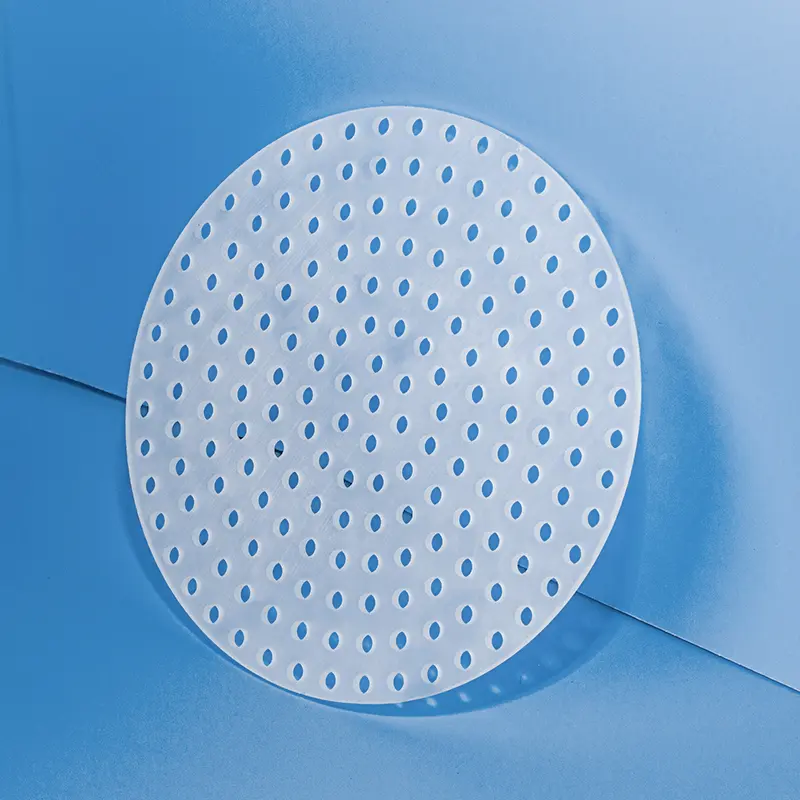

半導体グレード石英: 半導体製造用のプロセスチューブやキャリアなどの高純度部品。

特注加工部品: お客様固有の設計および仕様に合わせて、複雑な部品を製造できます。

はい。特注加工(カスタム加工)は、当社の事業の中核です。10年以上にわたる専門的な経験を活かし、お客様企業と提携し、専門的なOEM/ODMサービスを提供しております。当社の加工技術には、溶接、研削、穴あけ、研磨、曲げ加工、その他さまざまな精密加工技術が含まれており、お客様の厳密なご要望にお応えする部品を製造いたします。

品質は当社の製造プロセスにおいて最も重要です。当社はISO 9001:2015認証取得メーカーであり、当社のプロセスが国際的な品質管理基準を満たしていることを保証します。また、当社の製品は純度と性能に関して厳格なSGS試験を受けています。当社は高純度原材料(SiO2 99.998%まで)を使用し、優れた熱安定性、高温耐性、化学的不活性を持つ溶融石英および溶融シリカ製品を製造しています。

当社はプロセスを最大限に効率化しました:

RFQ(見積依頼)を提出:ウェブサイトのお問い合わせフォームまたはEメールで、技術図面、仕様、要件をお送りください。

迅速な対応: 数分以内に初回返信を、30分以内に詳細なご連絡を差し上げます。

設計・提案:24時間以内に詳細な設計提案と競争力のある見積もりをお届けします。

試作・生産:承認後、お客様の納期に間に合わせるため、迅速に試作から本格的な量産へと移行いたします。

Aoxin Quartzとの提携には、いくつかの重要なメリットがあります:

実証された専門知識:業界で10年以上の経験を持つ当社には、複雑な課題に取り組むための技術的知見があります。

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

競争力のある価値:主要な石英生産拠点に位置することで、効率的なサプライチェーンと先進的な製造技術を活用し、競争力のある価格で卓越した品質を提供しています。

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.