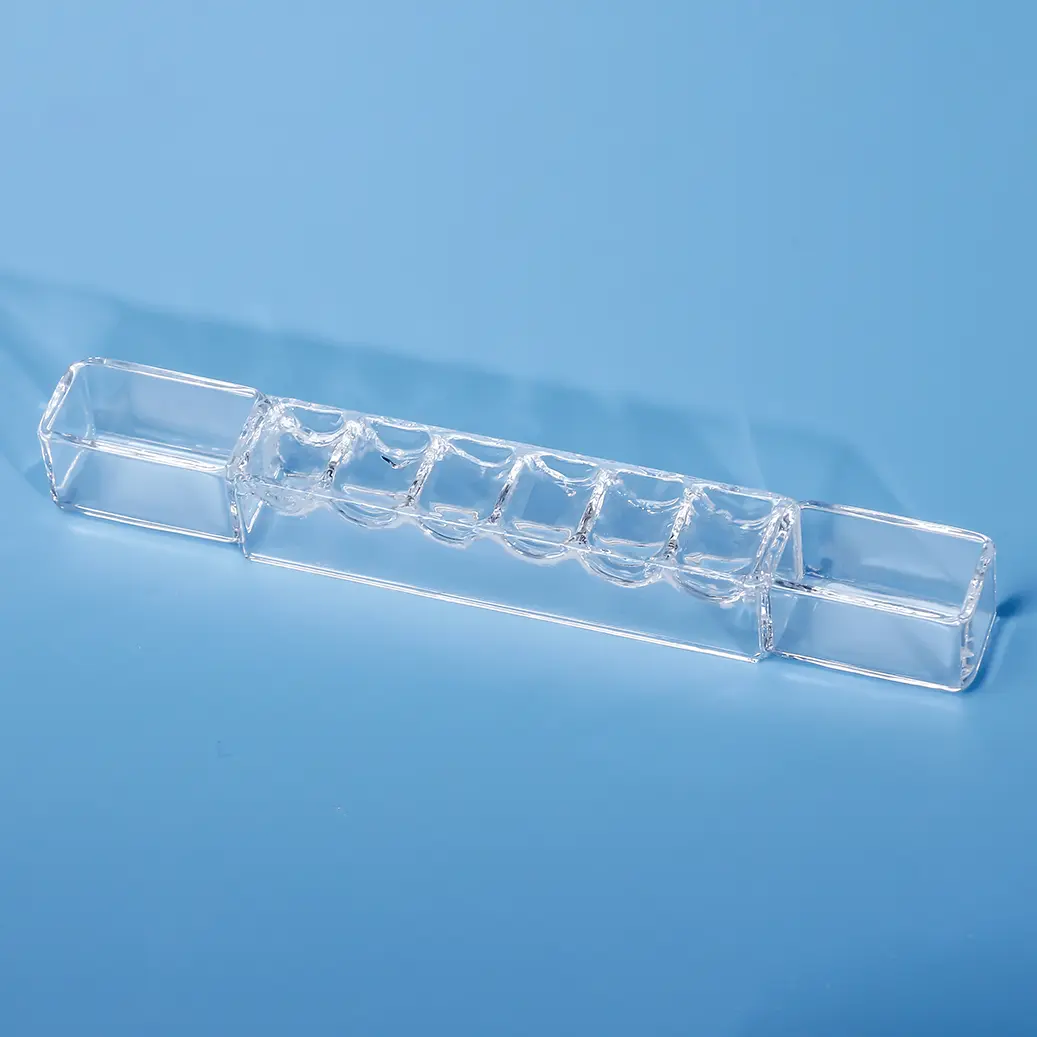

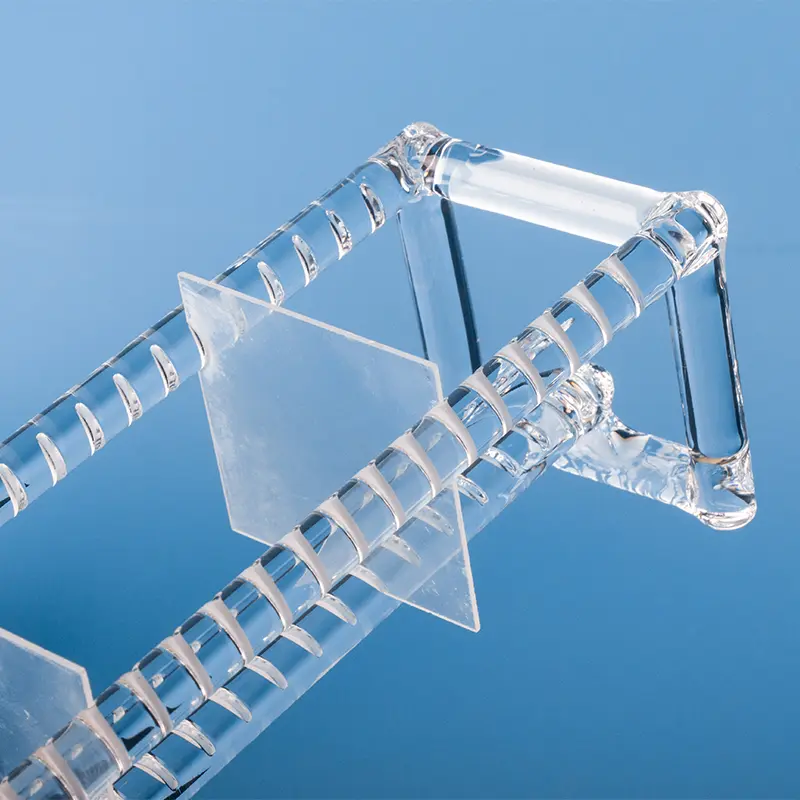

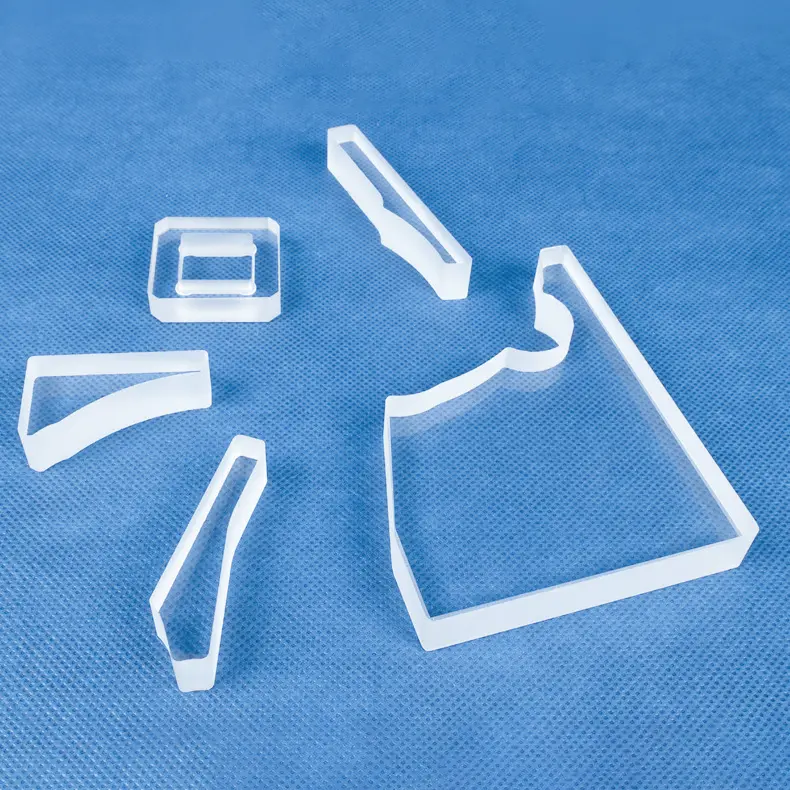

당사의 맞춤형 석영 분지형 튜브 반응기 및 다중 포트 용기는 복잡한 화학 반응 및 고급 유체 처리를 위해 정밀하게 설계되었습니다. 고순도 용융 실리카로 제작된 이 맞춤형 반응기는 탁월한 내화학성, 높은 열 안정성 및 우수한 UV-Vis 광 투과율을 제공합니다. 다상 합성, 플로우 화학 및 특수 실험실 설정에 이상적이며, 고객의 정확한 공정 요구 사항을 충족하는 맞춤형 솔루션을 제공합니다.

| 속성 내용 | 속성 값 |

|---|---|

| SiO2 | 99.99% |

| 밀도 | 2.2×10³ kg/cm³ |

| 경도 | 모스 경도 5.5 - 6.5; 누프 경도 570 (100g 하중) |

| 인장 강도 | 4.8 × 10⁷ Pa (48 N/mm² 또는 48 MPa); 7,000 psi |

| 압축 강도 | >1.1×10⁹ Pa (160,000 psi) |

| 열팽창 계수 | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| 열전도도 | 1.4W/m-°C |

| 비열 | 670 J/kg-°C |

| 연화점 | 1730°C(3146°F) |

| 어닐링점 | 1210°C(2210°F) |

| 변형점 | 1120°C(2048°F) |

| 작업 온도 | 1200°C(2192°F) |

| 전기 저항률 | 7×10⁷ 옴 cm(350°C) |

| 크기 | 맞춤 제작 가능 |

| 로고 | 맞춤형 로고 적용 가능 |

탁월한 화학적 안정성

주로 이산화규소(SiO2)로 구성된 석영 유리는 다양한 강산, 강염기 및 유기 용매에 대한 탁월한 부식 저항성을 제공합니다. 이로 인해 반응기는 다양한 화학 반응 환경에 이상적으로 적합합니다.

우수한 광학적 특성

석영 유리는 뛰어난 광학적 투명성을 나타내어, 이러한 반응기는 빛 투과 또는 분광 분석이 필요한 실험에 완벽하게 적합합니다. 고품질의 빛 상호작용이 필수적인 광화학 반응 및 스펙트럼 검출이 그 예입니다.

높은 내열성

석영 유리의 고유한 열 안정성은 이 반응기들이 고온을 견딜 수 있도록 하여, 고온 합성이나 열분해와 같은 고온 조건이 필요한 까다로운 화학 반응에 적합하게 만듭니다.

견고한 기계적 강도

석영 유리는 상당한 기계적 강도를 제공하여 고압 조건에서 안정성을 보장하며, 이 반응기들을 고압 반응 환경에 신뢰할 수 있게 만듭니다

응용 시나리오

석영 분기관 반응기의 일반적인 작동 온도 범위는 -50°C에서 1200°C 사이입니다. 그러나 정확한 온도 한계는 석영 유리의 순도와 적용된 특정 제조 공정에 따라 달라집니다. 고순도 석영 유리는 향상된 열 안정성을 제공하여 고온에서도 그 형태를 유지합니다. 따라서 실험의 온도 요구 사항에 따라 적절한 석영 유리 등급을 선택하고, 과도한 열로 인한 잠재적인 재료 파손이나 성능 저하를 방지하기 위해 반응기를 안전 작동 범위 내에서 가동하는 것이 중요합니다

석영 분기관 반응기의 적절한 세척 및 유지보수는 최적의 성능과 긴 수명을 보장하는 데 필수적입니다. 사용 전에는 항상 반응기에 균열이나 손상 징후가 있는지 먼저 검사해야 합니다. 각 사용 후에는 잔류물 축적 및 잠재적인 부식을 방지하기 위해 반응기 내부를 탈이온수 또는 적합한 용매로 즉시 세척하십시오. 고착된 얼룩이나 제거하기 어려운 침전물이 있는 경우, 초음파 세척기 또는 특수 세척액 사용을 고려하십시오. 반응기의 밀봉부와 커넥터가 손상되지 않고 누출이 없는지 확인하기 위한 정기적인 검사가 필요합니다. 보관 시에는 직사광선 및 잠재적인 기계적 손상으로부터 보호되는 건조하고 서늘하며 먼지 없는 환경에 반응기를 보관하십시오

석영 분기관 반응기를 사용할 때 다음 안전 조치를 준수하는 것이 매우 중요합니다. 첫째, 화학 시약 또는 고온 노출로부터 보호하기 위해 장갑, 보안경, 실험복과 같은 적절한 개인 보호 장비(PPE)를 항상 착용하십시오. 둘째, 고온 및 고압 조건에서 작동할 때는 과압으로 인한 폭발을 방지하기 위해 반응기의 밀봉부가 단단히 고정되어 있는지 확인하십시오. 또한, 확립된 실험 조작 절차를 엄격히 따르고, 반응기 파손을 방지하기 위해 날카로운 진동이나 충격을 피하십시오. 마지막으로, 강산 및 강염기와 같은 부식성 시약을 다룰 때는 반응기의 호환성 및 화학적 부식에 대한 재료 저항성을 확인하여 손상을 방지하도록 특별히 주의하십시오

자주 묻는 질문

당사는 고순도 석영 유리 부품의 원스톱 제조를 전문으로 합니다. 주요 제품군은 다음과 같습니다:

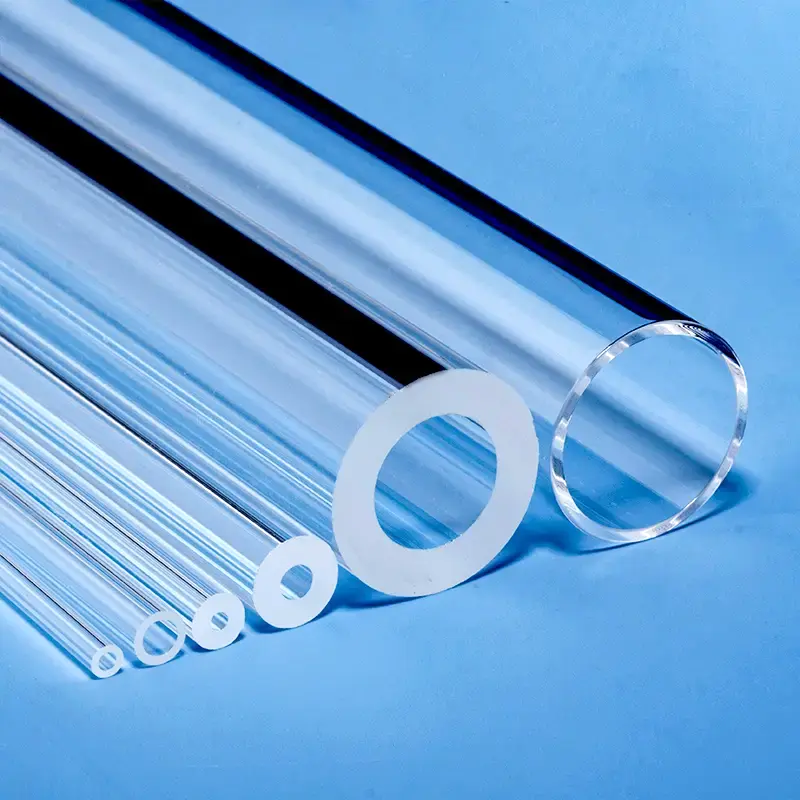

석영 튜브 및 로드: 다양한 직경 및 사양.

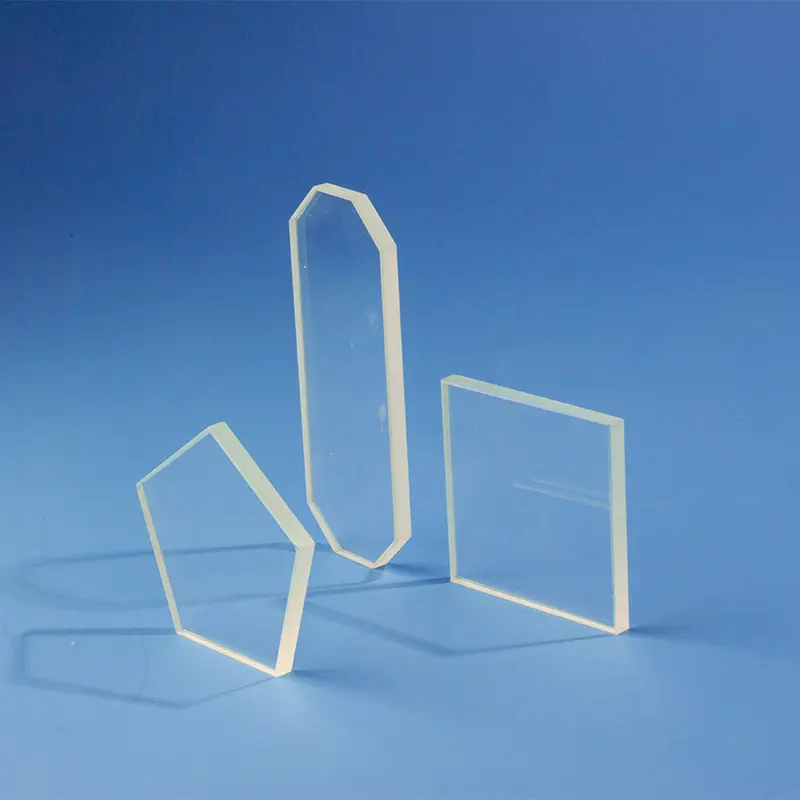

석영 플레이트 및 디스크: 광학 및 산업용 정밀 절단 및 연마.

석영 실험용 기구: 비커, 플라스크, 보트 등을 포함한 다양한 표준 및 맞춤형 초자 기구 일체.

반도체 등급 석영: 반도체 제조를 위한 공정 튜브 및 캐리어와 같은 고순도 부품.

맞춤 제작 부품: 고객의 고유한 설계 및 사양에 맞춰 복잡한 부품을 생산할 수 있습니다.

네. 맞춤 제작은 당사 비즈니스의 핵심입니다. 10년 이상의 전문화된 경험을 바탕으로, 당사는 기업들과 협력하여 전문적인 OEM/ODM 서비스를 제공합니다. 당사의 역량에는 용접, 연삭, 드릴링, 연마, 벤딩을 비롯한 다양한 정밀 가공 기술이 포함되며, 고객의 정확한 요구사항을 충족하는 부품을 제작합니다.

품질은 당사의 제조 공정에서 가장 중요합니다. 당사는 ISO 9001:2015 인증을 받은 제조업체로서, 당사의 공정이 국제 품질 관리 표준을 충족하도록 보장합니다.당사의 제품은 또한 순도 및 성능에 대해 엄격한 SGS 테스트를 거칩니다. 당사는 고순도 원료(최대 99.998% SiO2)를 사용하여 탁월한 열 안정성, 고온 저항성 및 화학적 불활성을 지닌 용융 석영 및 퓨즈드 실리카 제품을 생산합니다.

당사는 프로세스를 최대한 효율적으로 간소화했습니다:

RFQ 제출: 당사 웹사이트 문의 양식 또는 이메일을 통해 기술 도면, 사양 및 요구사항을 보내주십시오.

신속한 응답: 수분 내에 초기 응답을, 30분 이내에 상세한 소통을 기대하실 수 있습니다.

설계 및 제안: 24시간 이내에 상세한 설계 제안과 경쟁력 있는 견적을 제공해 드립니다.

프로토타입 제작 및 생산: 승인 후, 당사는 고객의 기한을 맞추기 위해 프로토타입 제작에서 본격적인 생산으로 신속하게 전환합니다.

Aoxin Quartz와의 파트너십은 여러 가지 주요 이점을 제공합니다:

입증된 전문성: 10년 이상의 업계 경력을 바탕으로, 당사는 복잡한 과제를 해결할 기술적 지식을 갖추고 있습니다.

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

경쟁력 있는 가치: 주요 석영 생산 허브에 위치하여 효율적인 공급망과 첨단 제조 기술을 활용함으로써, 경쟁력 있는 가격으로 탁월한 품질을 제공합니다.

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.