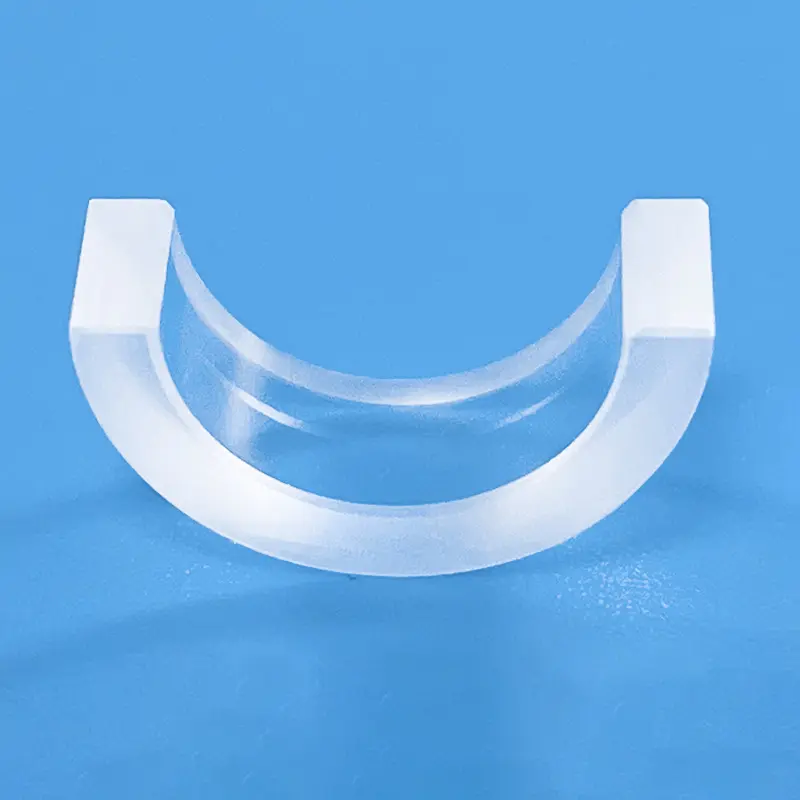

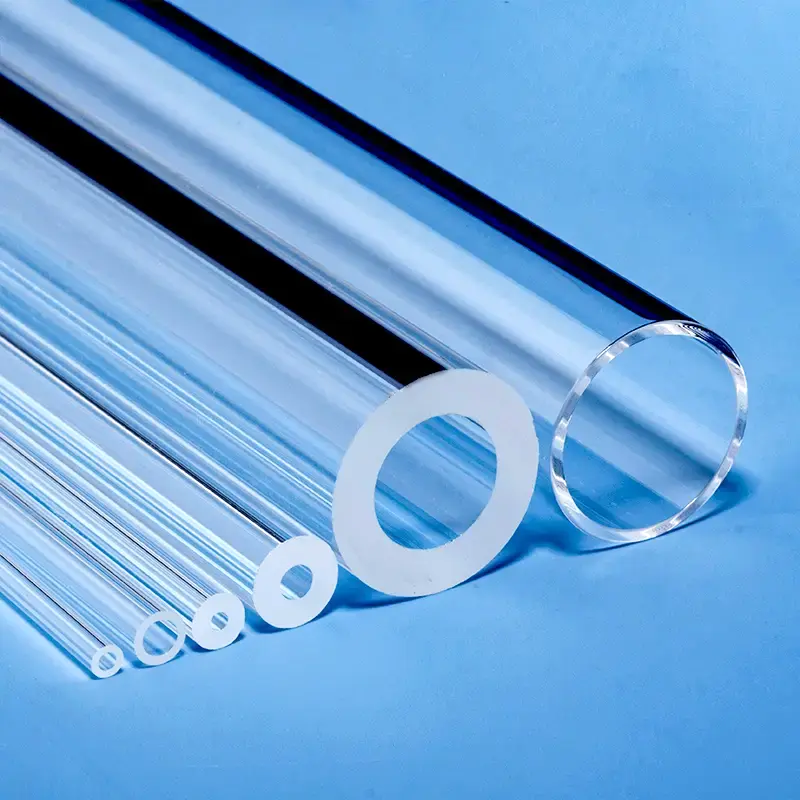

Матовая кварцевая трубка, образующаяся путем добавления специфических красителей или оксидов в процессе производства, представляет собой непрозрачный белый кварцевый материал. В основном состоящая из высокочистого кварцевого стекла, она демонстрирует исключительную стойкость к высоким температурам, коррозии и старению.

| OD | ID | WT | L(mm) |

|---|---|---|---|

| 1mm | 0.5mm | 0.25mm | 1–6000 мм (на заказ) |

| 1.5mm | 0.8mm | 0.35mm | 1–6000 мм (на заказ) |

| 2mm | 1mm | 0.5mm | 1–6000 мм (на заказ) |

| 2.5mm | 1.5mm | 0.5mm | 1–6000 мм (на заказ) |

| 3mm | 2mm | 0.5mm | 1–6000 мм (на заказ) |

| 3mm | 1mm | 1mm | 1–6000 мм (на заказ) |

| 4mm | 3mm | 0.5mm | 1–6000 мм (на заказ) |

| 4mm | 2mm | 1mm | 1–6000 мм (на заказ) |

| 4mm | 1mm | 1.5mm | 1–6000 мм (на заказ) |

| 5mm | 4mm | 0.5mm | 1–6000 мм (на заказ) |

| 5mm | 3mm | 1mm | 1–6000 мм (на заказ) |

| 5mm | 2mm | 1.5mm | 1–6000 мм (на заказ) |

| 5.5mm | 3.5mm | 1mm | 1–6000 мм (на заказ) |

| 6mm | 5mm | 0.5mm | 1–6000 мм (на заказ) |

| 6mm | 4mm | 1mm | 1–6000 мм (на заказ) |

| 6mm | 3mm | 1.5mm | 1–6000 мм (на заказ) |

| 6mm | 2mm | 2mm | 1–6000 мм (на заказ) |

| 6.5mm | 4.5mm | 1mm | 1–6000 мм (на заказ) |

| 7mm | 5mm | 1mm | 1–6000 мм (на заказ) |

| 7mm | 4mm | 1.5mm | 1–6000 мм (на заказ) |

| 7.5mm | 5.5mm | 1mm | 1–6000 мм (на заказ) |

| 8mm | 6mm | 1mm | 1–6000 мм (на заказ) |

| 8mm | 5mm | 1.5mm | 1–6000 мм (на заказ) |

| 8.5mm | 6.5mm | 1mm | 1–6000 мм (на заказ) |

| 9mm | 7mm | 1mm | 1–6000 мм (на заказ) |

| 9mm | 6mm | 1.5mm | 1–6000 мм (на заказ) |

| 9mm | 5mm | 2mm | 1–6000 мм (на заказ) |

| 10mm | 8mm | 1mm | 1–6000 мм (на заказ) |

| 10mm | 7mm | 1.5mm | 1–6000 мм (на заказ) |

| 10mm | 6mm | 2mm | 1–6000 мм (на заказ) |

| 10mm | 4mm | 3mm | 1–6000 мм (на заказ) |

| 10mm | 2mm | 4mm | 1–6000 мм (на заказ) |

| 11mm | 9mm | 1mm | 1–6000 мм (на заказ) |

| 11mm | 8mm | 1.5mm | 1–6000 мм (на заказ) |

| 11mm | 7mm | 2mm | 1–6000 мм (на заказ) |

| 11mm | 5mm | 3mm | 1–6000 мм (на заказ) |

| 12mm | 10mm | 1mm | 1–6000 мм (на заказ) |

| 12mm | 8mm | 2mm | 1–6000 мм (на заказ) |

| 12mm | 4mm | 4mm | 1–6000 мм (на заказ) |

| 13mm | 11mm | 1mm | 1–6000 мм (на заказ) |

| 13mm | 10mm | 1.5mm | 1–6000 мм (на заказ) |

| 13mm | 9mm | 2mm | 1–6000 мм (на заказ) |

| 14mm | 12mm | 1mm | 1–6000 мм (на заказ) |

| 14mm | 10mm | 2mm | 1–6000 мм (на заказ) |

| 15mm | 13mm | 1mm | 1–6000 мм (на заказ) |

| 15mm | 11mm | 2mm | 1–6000 мм (на заказ) |

| 15mm | 9mm | 3mm | 1–6000 мм (на заказ) |

| 16mm | 14mm | 1mm | 1–6000 мм (на заказ) |

| 16mm | 13mm | 1.5mm | 1–6000 мм (на заказ) |

| 16mm | 12mm | 2mm | 1–6000 мм (на заказ) |

| 16mm | 10mm | 3mm | 1–6000 мм (на заказ) |

| 17mm | 15mm | 1mm | 1–6000 мм (на заказ) |

| 17mm | 14mm | 1.5mm | 1–6000 мм (на заказ) |

| 18mm | 16mm | 1mm | 1–6000 мм (на заказ) |

| 18mm | 15mm | 1.5mm | 1–6000 мм (на заказ) |

| 18mm | 14mm | 2mm | 1–6000 мм (на заказ) |

| 18mm | 12mm | 3mm | 1–6000 мм (на заказ) |

| 18mm | 11mm | 3.5mm | 1–6000 мм (на заказ) |

| 19mm | 17mm | 1mm | 1–6000 мм (на заказ) |

| 19mm | 16mm | 1.5mm | 1–6000 мм (на заказ) |

| 19mm | 13mm | 3mm | 1–6000 мм (на заказ) |

| 20mm | 18mm | 1mm | 1–6000 мм (на заказ) |

| 20mm | 17mm | 1.5mm | 1–6000 мм (на заказ) |

| 20mm | 16mm | 2mm | 1–6000 мм (на заказ) |

| 20mm | 14mm | 3mm | 1–6000 мм (на заказ) |

| 25mm | 19mm | 3mm | 1–6000 мм (на заказ) |

| 25mm | 21mm | 2mm | 1–6000 мм (на заказ) |

| 25mm | 21mm | 2mm | 1–6000 мм (на заказ) |

| 25mm | 21mm | 2mm | 1–6000 мм (на заказ) |

| 25mm | 21mm | 2mm | 1–6000 мм (на заказ) |

| 25mm | 20mm | 2.5mm | 1–6000 мм (на заказ) |

| 25mm | 20mm | 2.5mm | 1–6000 мм (на заказ) |

| 25mm | 20mm | 2.5mm | 1–6000 мм (на заказ) |

| 26mm | 21mm | 2.5mm | 1–6000 мм (на заказ) |

| 28mm | 24mm | 2mm | 1–6000 мм (на заказ) |

| 30mm | 26mm | 2mm | 1–6000 мм (на заказ) |

| 30mm | 24mm | 3mm | 1–6000 мм (на заказ) |

| 35mm | 30mm | 2.5mm | 1–6000 мм (на заказ) |

| 40mm | 34mm | 3mm | 1–6000 мм (на заказ) |

| 40mm | 34mm | 3mm | 1–6000 мм (на заказ) |

| 40mm | 34mm | 3mm | 1–6000 мм (на заказ) |

| 40mm | 34mm | 3mm | 1–6000 мм (на заказ) |

| 40mm | 32mm | 4mm | 1–6000 мм (на заказ) |

| 40mm | 32mm | 4mm | 1–6000 мм (на заказ) |

| 40mm | 32mm | 4mm | 1–6000 мм (на заказ) |

| 40mm | 32mm | 4mm | 1–6000 мм (на заказ) |

| 40mm | 32mm | 4mm | 1–6000 мм (на заказ) |

| 45mm | 39mm | 3mm | 1–6000 мм (на заказ) |

| 50mm | 44mm | 3mm | 1–6000 мм (на заказ) |

| 50mm | 44mm | 3mm | 1–6000 мм (на заказ) |

| 50mm | 44mm | 3mm | 1–6000 мм (на заказ) |

| 50mm | 44mm | 3mm | 1–6000 мм (на заказ) |

| 50mm | 44mm | 3mm | 1–6000 мм (на заказ) |

| 50mm | 44mm | 3mm | 1–6000 мм (на заказ) |

| 50mm | 44mm | 3mm | 1–6000 мм (на заказ) |

| 50mm | 44mm | 3mm | 1–6000 мм (на заказ) |

| 50mm | 44mm | 3mm | 1–6000 мм (на заказ) |

| 50mm | 44mm | 3mm | 1–6000 мм (на заказ) |

| 50mm | 42mm | 4mm | 1–6000 мм (на заказ) |

| 50mm | 42mm | 4mm | 1–6000 мм (на заказ) |

| 50mm | 42mm | 4mm | 1–6000 мм (на заказ) |

| 50mm | 42mm | 4mm | 1–6000 мм (на заказ) |

| 50mm | 42mm | 4mm | 1–6000 мм (на заказ) |

| 50mm | 42mm | 4mm | 1–6000 мм (на заказ) |

| 50mm | 40mm | 5mm | 1–6000 мм (на заказ) |

| 50mm | 40mm | 5mm | 1–6000 мм (на заказ) |

| 60mm | 54mm | 3mm | 1–6000 мм (на заказ) |

| 60mm | 54mm | 3mm | 1–6000 мм (на заказ) |

| 60mm | 54mm | 3mm | 1–6000 мм (на заказ) |

| 60mm | 54mm | 3mm | 1–6000 мм (на заказ) |

| 60mm | 52mm | 4mm | 1–6000 мм (на заказ) |

| 60mm | 52mm | 4mm | 1–6000 мм (на заказ) |

| 60mm | 50mm | 5mm | 1–6000 мм (на заказ) |

| 60mm | 50mm | 5mm | 1–6000 мм (на заказ) |

| 80mm | 74mm | 3mm | 1–6000 мм (на заказ) |

| 80mm | 74mm | 3mm | 1–6000 мм (на заказ) |

| 80mm | 74mm | 3mm | 1–6000 мм (на заказ) |

| 80mm | 72mm | 4mm | 1–6000 мм (на заказ) |

| 80mm | 72mm | 4mm | 1–6000 мм (на заказ) |

| 80mm | 70mm | 5mm | 1–6000 мм (на заказ) |

| 80mm | 70mm | 5mm | 1–6000 мм (на заказ) |

| 85mm | 79mm | 3mm | 1–6000 мм (на заказ) |

| 90mm | 80mm | 5mm | 1–6000 мм (на заказ) |

| 100mm | 94mm | 3mm | 1–6000 мм (на заказ) |

| 100mm | 94mm | 3mm | 1–6000 мм (на заказ) |

| 100mm | 94mm | 3mm | 1–6000 мм (на заказ) |

| 100mm | 92mm | 4mm | 1–6000 мм (на заказ) |

| 100mm | 92mm | 4mm | 1–6000 мм (на заказ) |

| 100mm | 90mm | 5mm | 1–6000 мм (на заказ) |

| 100mm | 90mm | 5mm | 1–6000 мм (на заказ) |

| 120mm | 112mm | 4mm | 1–6000 мм (на заказ) |

| 120mm | 110mm | 5mm | 1–6000 мм (на заказ) |

| 120mm | 112mm | 4mm | 1–6000 мм (на заказ) |

| 120mm | 110mm | 5mm | 1–6000 мм (на заказ) |

| 130mm | 120mm | 5mm | 1–6000 мм (на заказ) |

| 130mm | 124mm | 3mm | 1–6000 мм (на заказ) |

| 130mm | 124mm | 3mm | 1–6000 мм (на заказ) |

| 130mm | 120mm | 5mm | 1–6000 мм (на заказ) |

| 130mm | 120mm | 5mm | 1–6000 мм (на заказ) |

| 140mm | 130mm | 5mm | 1–6000 мм (на заказ) |

| 140mm | 130mm | 5mm | 1–6000 мм (на заказ) |

| 150mm | 140mm | 5mm | 1–6000 мм (на заказ) |

| 150mm | 140mm | 5mm | 1–6000 мм (на заказ) |

| 150mm | 140mm | 5mm | 1–6000 мм (на заказ) |

| 180mm | 170mm | 5mm | 1–6000 мм (на заказ) |

| 180mm | 170mm | 5mm | 1–6000 мм (на заказ) |

| 180mm | 170mm | 5mm | 1–6000 мм (на заказ) |

| 200mm | 190mm | 5mm | 1–6000 мм (на заказ) |

| 200mm | 190mm | 5mm | 1–6000 мм (на заказ) |

| 200mm | 190mm | 5mm | 1–6000 мм (на заказ) |

- Способ оплаты: Банковский перевод или предоплата, в зависимости от объема заказа

- Срок поставки: В зависимости от объема заказа

- Способ транспортировки: Морские или воздушные перевозки, в зависимости от клиента

Примечания:

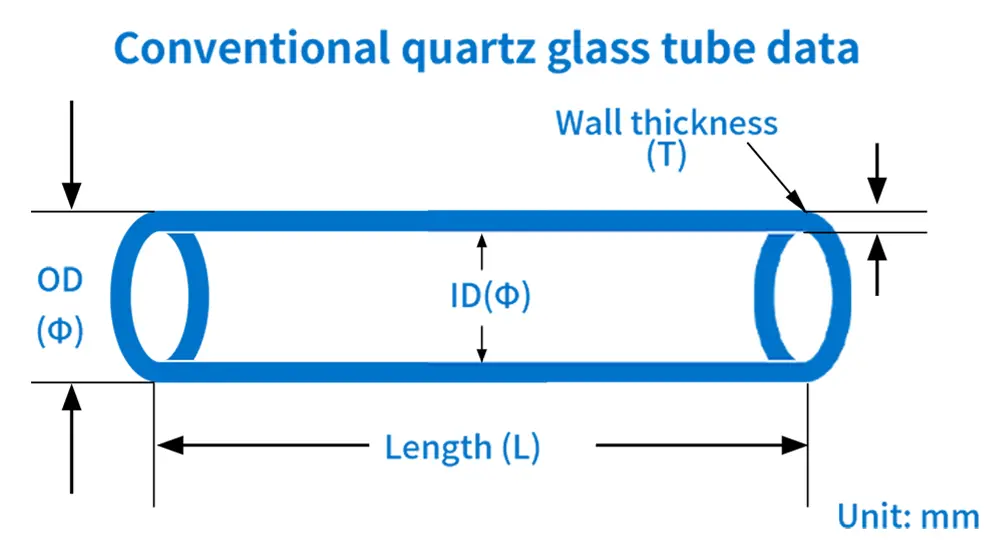

Для подтверждения заказа необходимо предоставить следующие параметры: ① Наружный диаметр (НД) ② Внутренний диаметр (ВД) ③ Толщина стенки (ТС) ④ Длина (мм) ⑤ Количество

| Содержание свойств | Значения свойств |

|---|---|

| SiO2 | 99.99% |

| Плотность | 2,2×10³ кг/см³ |

| Твердость | Твердость по шкале Мооса 5,5 - 6,5; Твердость по Кнупу 570 (при нагрузке 100 г) |

| Предел прочности при растяжении | 4,8 × 10⁷ Па (48 Н/мм² или 48 МПа); 7 000 фунтов на квадратный дюйм (psi) |

| Предел прочности при сжатии | >1.1×10⁹ Pa (160,000 psi) |

| Коэффициент теплового расширения | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| Теплопроводность | 1,4 Вт/м-°C |

| Удельная теплоемкость | 670 Дж/кг-°C |

| Температура размягчения | 1730 °C (3146 °F) |

| Точка отжига | 1210 °C (2210 °F) |

| Точка напряжения | 1120 °C (2048 °F) |

| Рабочая температура | 1200°C (2192°F) |

| Удельное электрическое сопротивление | 7×10⁷ Ом см (350°C) |

| Размер | Индивидуальный заказ |

| Логотип | Нанесение логотипа по заказу |

Высокая термостойкость

Может использоваться в высокотемпературной среде в течение длительных периодов без деформации или повреждений.

Сильная коррозионная стойкость

Устойчив к коррозии от обычных химикатов.

Высокая прозрачность

Несмотря на молочно-белый внешний вид, он сохраняет хорошую светопропускную способность, устоичив к загрязнениям и легок в очистке.

Высокая твердость

Обладает высокой твердостью, что позволяет ему выдерживать определенную степень физического удара.

Сценарий применения

Полупроводниковая промышленность

Это является важным компонентом в камерах реакций химического осаждения паром и в качестве материала оболочки для нагревательного оборудования, обеспечивая долговечность и стабильность оборудования для производства полупроводников при длительной работе при высокой температуре.

Химическая промышленность

Мильк-кварцевые трубки используются в химических реакторах и корпусах высокотемпературного нагревательного оборудования. Их коррозионная стойкость и высокая температурная стабильность имеют жизненно важное значение для поддержания стабильных химических реакционных процессов.

Предотвращение ударов и вибраций

Защитите трубку от ударов и вибраций, чтобы предотвратить ее поломку и деформацию.

Контролируемый нагрев

При использовании матовых кварцевых трубок для высокотемпературных применений следует тщательно выбирать подходящие методы нагрева и температуры, исходя из их термостойкости и рабочей среды. Избегайте чрезмерных температур, которые могут привести к деформации или повреждению.

Избегайте химического контакта.

Избегайте контакта с химическими веществами, особенно с кислотами и щелочами, чтобы защитить трубки от коррозии или обесцвечивания.

Регулярное обслуживание

Очищайте трубку мягкой тканью и теплой водой. Избегайте абразивных материалов или сильных кислотных/щелочных растворов. Защищайте трубку от прямых солнечных лучей и высокотемпературных условий, чтобы предотвратить старение и деформацию материала.

Матовые кварцевые трубки в основном используются в применениях, требующих дальнего инфракрасного нагрева, таких как обогреватели, дезинфекционные шкафы, микроволновые печи и другие электрические нагревательные приборы.

Матовые кварцевые трубки, получаемые в результате специального производственного процесса, имеют непрозрачный, матово-белый внешний вид. Состоящие преимущественно из высокочистого кварцевого стекла, они обладают отличной термической стабильностью и способны поглощать видимый свет и ближнюю инфракрасную радиацию, преобразуя их в дальнюю инфракрасную радиацию.

Матовые кварцевые трубки имеют светопропускание менее 10% при 500 нм, что значительно ниже, чем у прозрачных кварцевых трубок, обеспечивая лучшую непрозрачность.

Часто задаваемые вопросы

Мы специализируемся на комплексном производстве высокочистых кварцевых стекольных компонентов. Наши основные продуктовые линейки включают:

Кварцевые трубки и стержни: Широкий диапазон диаметров и спецификаций.

Кварцевые пластины и диски: Прецизионная резка и полировка для оптического и промышленного применения.

Кварцевая лабораторная посуда: Полный ассортимент стандартной и индивидуальной стеклянной посуды, включая стаканы, колбы и лодочки.

Кварц полупроводникового класса: Высокочистые компоненты, такие как технологические трубки и носители, для производства полупроводников.

Компоненты индивидуального изготовления: Мы можем производить сложные детали, адаптированные под ваши уникальные чертежи и спецификации.

Да. Индивидуальное изготовление является основой нашей деятельности. Имея более чем десятилетний специализированный опыт, мы сотрудничаем с компаниями, предлагая высококлассные услуги OEM/ODM. Наши возможности включают сварку, шлифовку, сверление, полировку, гибку и другие методы прецизионной обработки для создания компонентов, точно соответствующих вашим требованиям.

Качество является первостепенным в нашем производственном процессе. Мы являемся производителем, сертифицированным по ISO 9001:2015, гарантируя, что наши процессы соответствуют международным стандартам управления качеством.Наша продукция также проходит строгие испытания SGS на чистоту и производительность. Мы используем высокочистое сырье (до 99,998% SiO2) для производства изделий из плавленого кварца и плавленого диоксида кремния с исключительной термической стабильностью, высокой термостойкостью и химической инертностью.

Мы максимально оптимизировали наш процесс для обеспечения эффективности:

Отправьте запрос коммерческого предложения (RFQ): Присылайте нам свои технические чертежи, спецификации и требования через контактную форму на нашем сайте или по электронной почте.

Быстрый ответ: Вы можете ожидать первоначальный ответ в течение нескольких минут и подробное общение в течение получаса.

Дизайн и Коммерческое предложение: Мы предоставим подробное проектное предложение и конкурентоспособное коммерческое предложение в течение 24 часов.

Прототипирование и производство: После утверждения мы оперативно переходим от прототипирования к полномасштабному производству, чтобы уложиться в ваши сроки.

Сотрудничество с Aoxin Quartz предоставляет несколько ключевых преимуществ:

Проверенный опыт: Имея более чем 10-летний опыт работы в отрасли, мы обладаем техническими знаниями для решения сложных задач.

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

Конкурентная ценность: Расположенные в крупном центре по производству кварца, мы используем эффективную цепочку поставок и передовое производство, чтобы предложить исключительное качество по конкурентоспособной цене.

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.