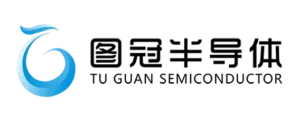

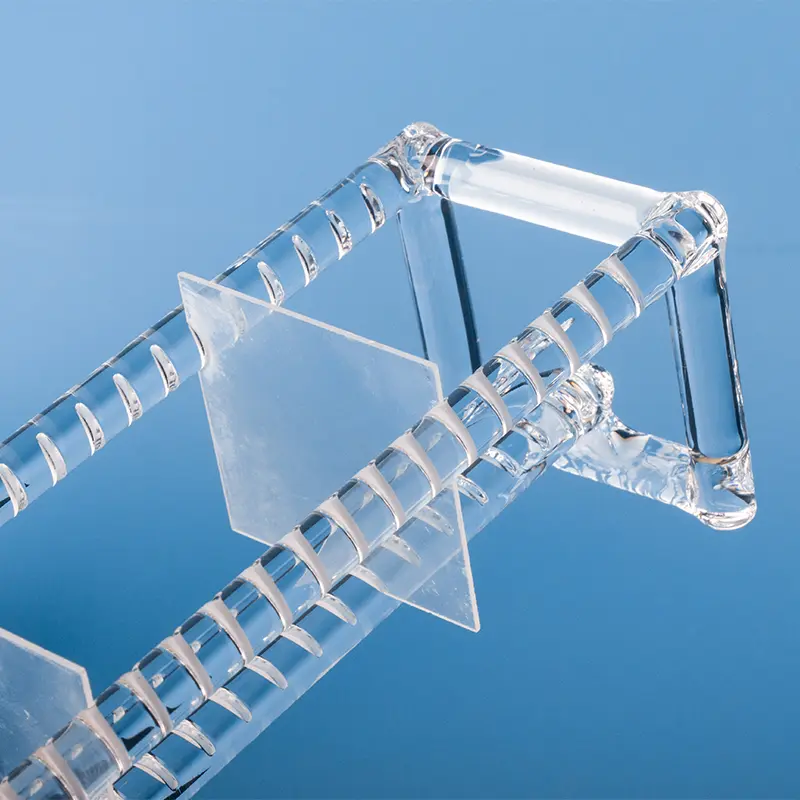

Our custom quartz branched tube reactors and multi-port vessels are precision-engineered for complex chemical reactions and advanced fluid processing. Crafted from high-purity fused silica, these bespoke reactors offer exceptional chemical resistance, high thermal stability, and excellent UV-Vis light transmission. Ideal for multi-phase synthesis, flow chemistry, and specialized laboratory setups, we provide tailored solutions to meet your precise process requirements.

| Property Content | Property Values |

|---|---|

| SiO2 | 99.99% |

| Density | 2.2×10³ kg/cm³ |

| Hardness | 5.5 - 6.5 Mohs' Scale 570 KHN 100 |

| Tensile Strength | 4.8×10⁷ Pa (N/mm2) (7000 psi) |

| Compression Strength | >1.1×10⁹ Pa (160,000 psi) |

| Coefficient of Thermal Expansion | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| Thermal Conductivity | 1.4 W/m·°C |

| Specific Heat | 670 J/kg·°C |

| Softening Point | 1730°C (3146°F) |

| Annealing Point | 1210°C (2210°F) |

| Strain Point | 1120°C (2048°F) |

| Work Temperature | 1200°C (2192°F) |

| Electrical Resistivity | 7×10⁷ ohm cm (350°C) |

| Size | Customized |

| Logo | Customized Logo Accept |

Exceptional Chemical Stability

Primarily composed of silicon dioxide (SiO2), quartz glass offers outstanding resistance to corrosion from a wide array of strong acids, strong bases, and organic solvents. This makes the reactors ideally suited for diverse chemical reaction environments.

Superior Optical Properties

Quartz glass exhibits excellent optical transparency, making these reactors perfect for experiments requiring light transmission or spectroscopic analysis. Examples include photochemical reactions and spectral detection where high-quality light interaction is crucial.

High Thermal Resistance

The inherent thermal stability of quartz glass allows these reactors to withstand high temperatures, thus making them suitable for demanding chemical reactions requiring high-temperature conditions like high-temperature synthesis or pyrolysis.

Robust Mechanical Strength

Quartz glass provides significant mechanical strength, ensuring stability under high-pressure conditions and making these reactors reliable for high-pressure reaction environments.

Application Scenario

Analytical Chemistry

In analytical chemistry, these reactors are frequently employed as reaction vessels or detection units in techniques like gas chromatography (GC), high-performance liquid chromatography (HPLC), and atomic fluorescence spectroscopy (AFS). They offer high sensitivity, precision, and excellent repeatability for reliable quantitative analysis.

Biotechnology and Life Sciences

In biotechnology and life sciences, quartz branch tube reactors are utilized in experiments such as PCR amplification, nucleic acid electrophoresis, and cell culture. Their ability to withstand high temperatures and pressures, combined with their excellent optical transparency, allows for real-time monitoring of amplification products and cellular processes.

The typical operating temperature range for a quartz branch tube reactor is between -50°C and 1200°C. However, the precise temperature limit is contingent on the purity of the quartz glass and the specific manufacturing processes employed. High-purity quartz glass provides enhanced thermal stability, maintaining its integrity at elevated temperatures. Therefore, it is crucial to select the appropriate quartz glass grade based on your experiment’s temperature requirements and to operate the reactor within its safe operating range to prevent potential material failure or compromised performance due to excessive heat.

Proper cleaning and maintenance of a quartz branch tube reactor are essential for ensuring its optimal performance and longevity. Initially, inspect the reactor for any signs of cracks or damage prior to use. After each use, promptly clean the reactor’s interior with deionized water or a suitable solvent to prevent the build-up of residues and potential corrosion. For persistent stains or difficult to remove deposits, consider using an ultrasonic cleaner or specialized cleaning solutions. Regular inspection of the reactor’s seals and connectors is necessary to ensure they remain intact and leak-free. During storage, keep the reactor in a dry, cool, dust-free environment, shielded from direct sunlight and potential mechanical damage.

When using a quartz branch tube reactor, it is crucial to adhere to the following safety measures: Firstly, always wear appropriate personal protective equipment (PPE), such as gloves, safety goggles, and a lab coat, to protect against exposure to chemical reagents or high temperatures. Secondly, when operating under high-temperature and high-pressure conditions, verify that the reactor’s seals are tight to prevent explosions from overpressure. Additionally, strictly follow established experimental operating procedures, and avoid any sharp vibrations or impacts to prevent breakage of the reactor. Finally, take special care when handling corrosive reagents such as strong acids and strong bases, verifying the reactor’s compatibility and material resistance to chemical corrosion to avoid damage.

Frequently asked questions

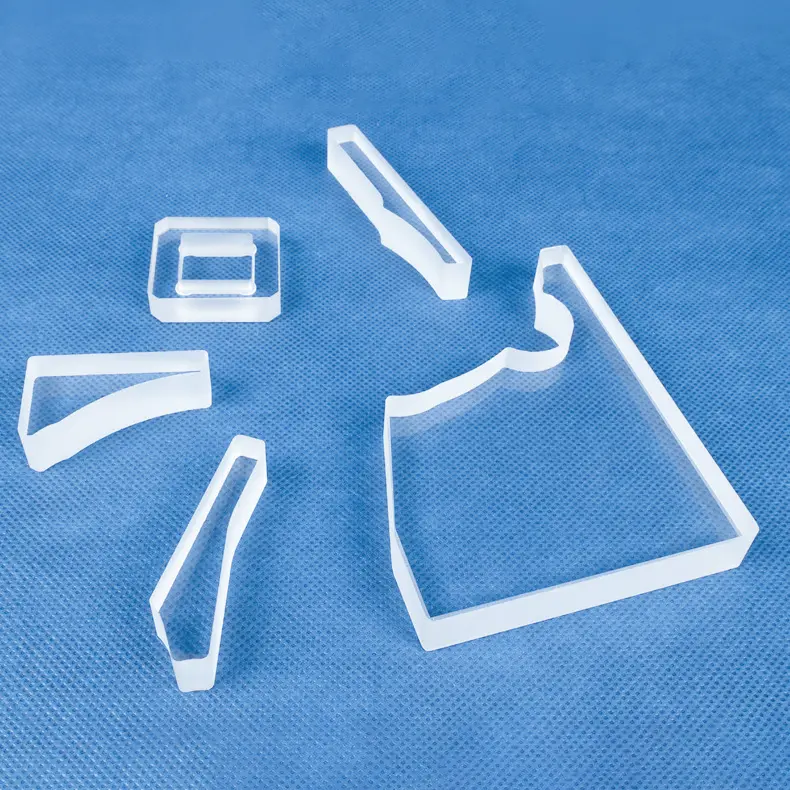

We specialize in the end-to-end manufacturing of high-purity quartz glass components. Our core product lines include:

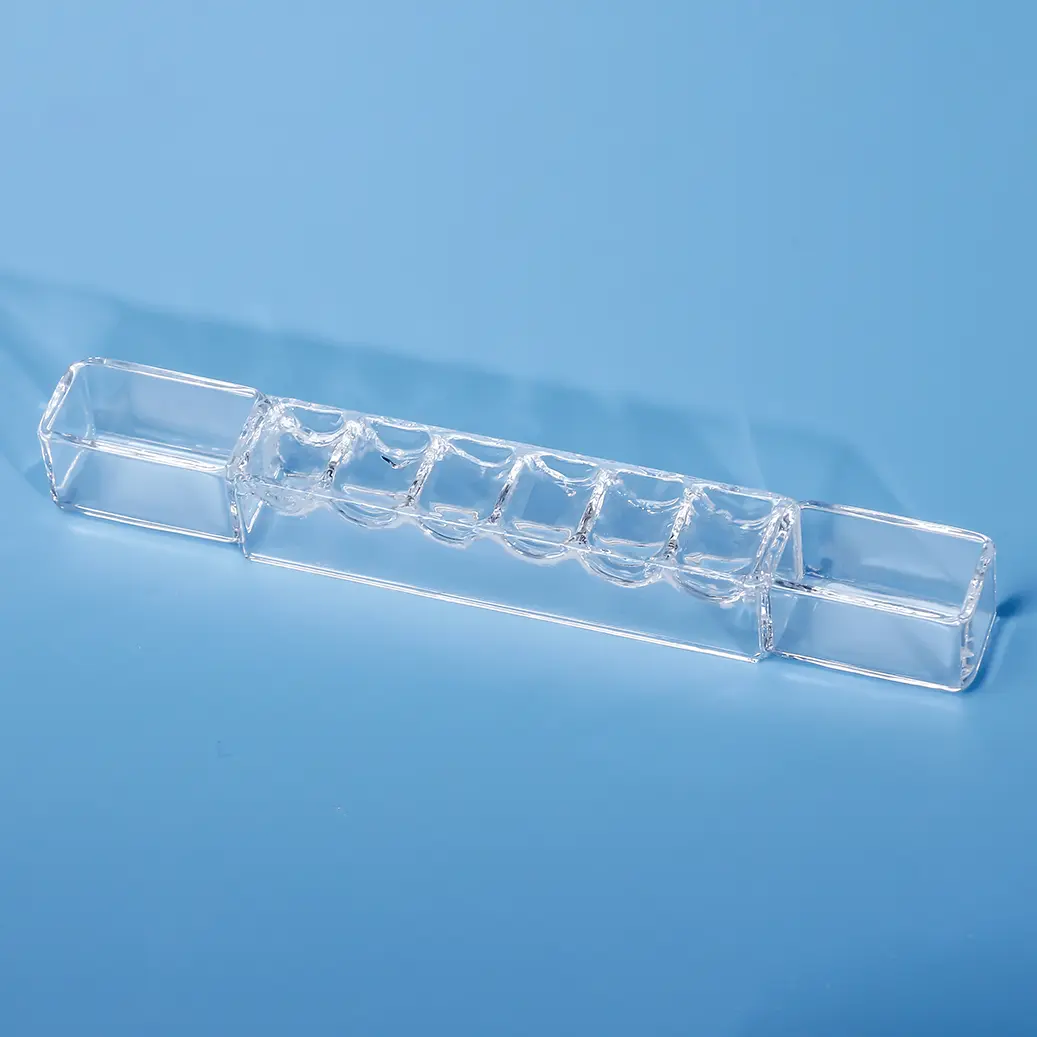

Quartz Tubing & Rods: A wide range of diameters and specifications.

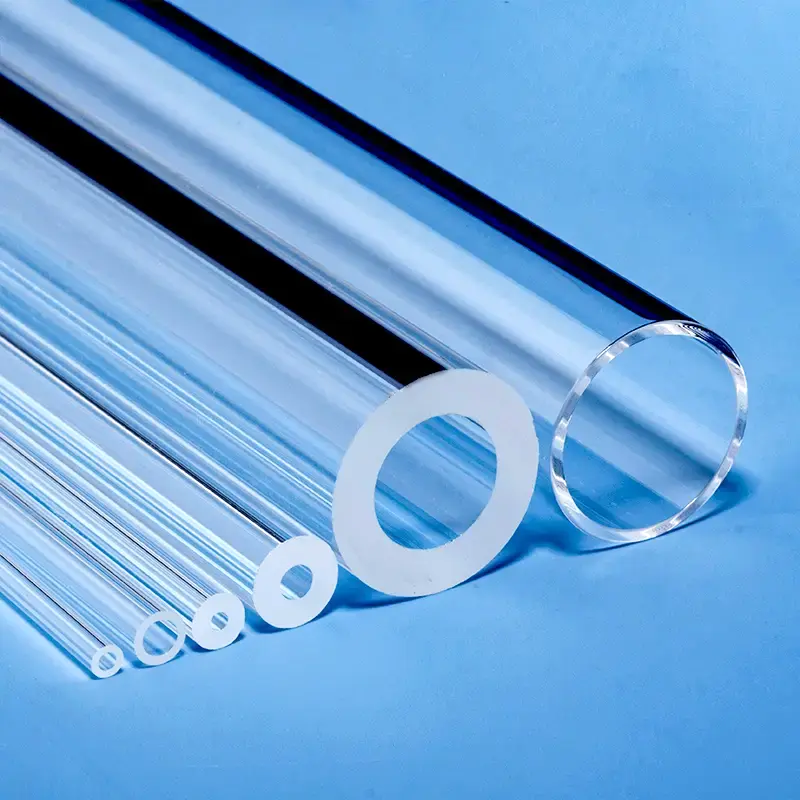

Quartz Plates & Discs: Precision-cut and polished for optical and industrial use.

Quartz Labware: A full suite of standard and custom glassware, including beakers, flasks, and boats.

Semiconductor-Grade Quartz: High-purity components like process tubes and carriers for semiconductor fabrication.

Custom Fabricated Components: We can produce complex parts tailored to your unique designs and specifications.

Yes. Custom fabrication is at the core of our business. With over a decade of specialized experience, we partner with companies to provide expert OEM/ODM services. Our capabilities include welding, grinding, drilling, polishing, bending, and other precision processing techniques to create components that meet your exact requirements.

Quality is paramount in our manufacturing process. We are an ISO 9001:2015 certified manufacturer, ensuring that our processes meet international quality management standards.Our products also undergo rigorous SGS testing for purity and performance. We use high-purity raw materials (up to 99.998% SiO2) to produce fused quartz and fused silica products with exceptional thermal stability, high-temperature resistance, and chemical inertness.

We've streamlined our process to be as efficient as possible:

Submit Your RFQ: Send us your technical drawings, specifications, and requirements via our website contact form or email.

Rapid Response: You can expect an initial response within minutes and detailed communication within half an hour.

Design & Proposal: We will deliver a detailed design proposal and a competitive quote within 24 hours.

Prototyping & Production: Upon approval, we move swiftly from prototyping to full-scale production to meet your deadlines.

Partnering with Aoxin Quartz offers several key advantages:

Proven Expertise: With 10+ years in the industry, we have the technical knowledge to tackle complex challenges.

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

Competitive Value: Located in a major quartz production hub, we leverage an efficient supply chain and advanced manufacturing to offer exceptional quality at a competitive price point.

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.