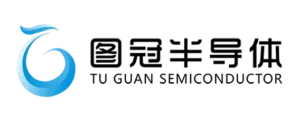

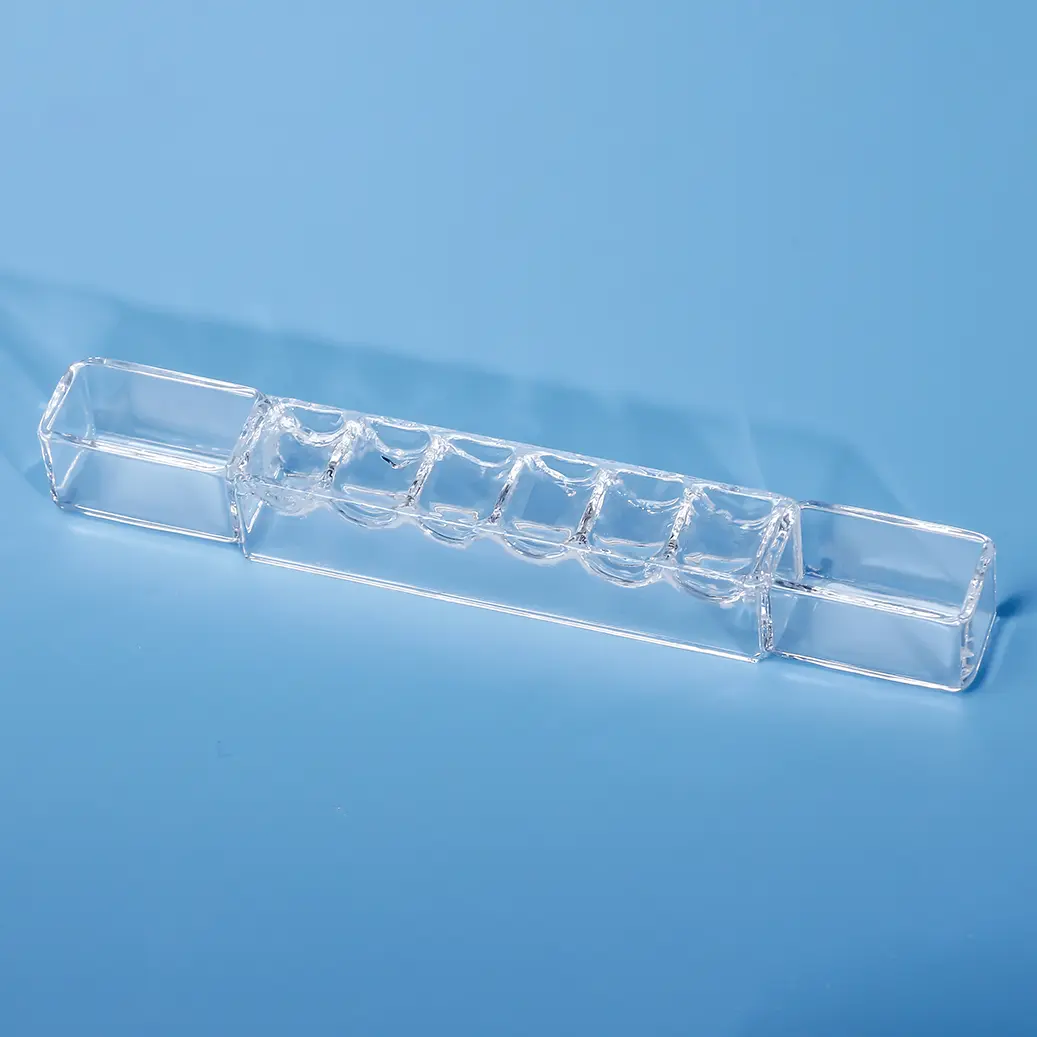

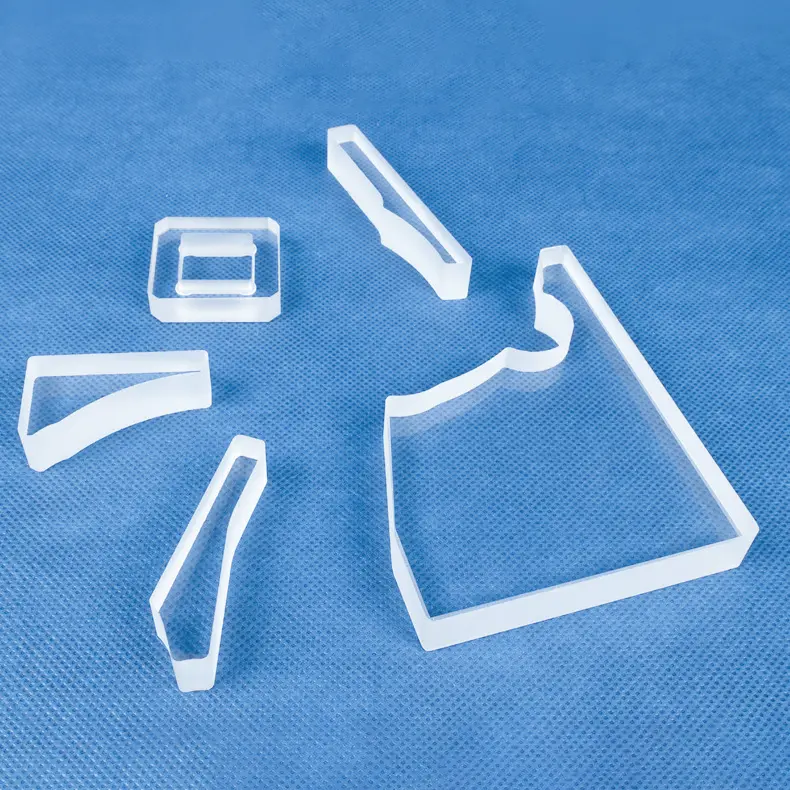

These custom high-purity fused quartz boats and sample holders are engineered for precise sulfur and elemental analysis. They offer exceptional resistance to high temperatures (up to 1200°C) and corrosive agents like acids and alkalis, ensuring sample integrity and longevity. Their high transmittance and non-contaminating properties make them ideal for demanding laboratory and industrial applications.

| Property Content | Property Values |

|---|---|

| SiO2 | 99.99% |

| Density | 2.2×10³ kg/cm³ |

| Hardness | 5.5 - 6.5 Mohs' Scale 570 KHN 100 |

| Tensile Strength | 4.8×10⁷ Pa (N/mm2) (7000 psi) |

| Compression Strength | >1.1×10⁹ Pa (160,000 psi) |

| Coefficient of Thermal Expansion | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| Thermal Conductivity | 1.4 W/m·°C |

| Specific Heat | 670 J/kg·°C |

| Softening Point | 1730°C (3146°F) |

| Annealing Point | 1210°C (2210°F) |

| Strain Point | 1120°C (2048°F) |

| Work Temperature | 1200°C (2192°F) |

| Electrical Resistivity | 7×10⁷ ohm cm (350°C) |

| Size | Customized |

| Logo | Customized Logo Accept |

Exceptional High Temperature & Corrosion Resistance

Engineered from fused quartz, these sample holders withstand temperatures up to 1200°C and offer superior resistance to strong acids and alkalis, ensuring reliability in harsh analytical environments.

Ultra-High Purity & Non-Contaminating

With SiO2 purity exceeding 99.99%, these quartz boats prevent sample contamination, guaranteeing accurate and reproducible results for sensitive elemental and sulfur analysis.

Superior Optical Transmittance & Durability

Featuring high transmittance, these quartz vessels allow for precise optical measurements, while their solid, bubble-free construction ensures long-lasting performance and structural integrity.

Customizable for Diverse Applications

Available in custom dimensions and shapes, these quartz boats and sample holders can be precisely tailored to meet the specific requirements of various sulfur analyzers and specialized laboratory applications.

Application Scenario

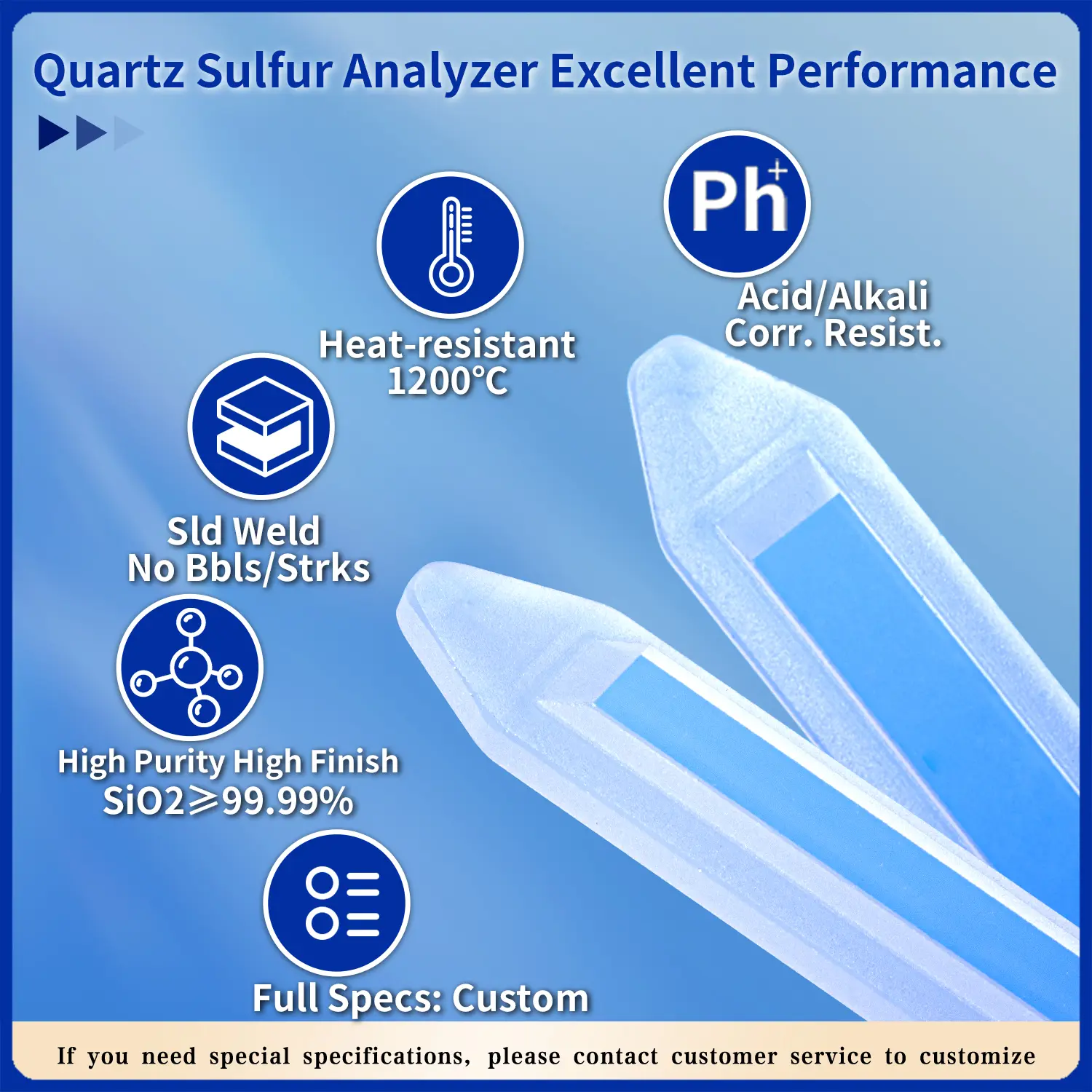

Sulfur and Elemental Analysis

Primarily used as sample boats or holders in combustion analyzers, X-ray fluorescence (XRF) spectroscopy, and other instrumental methods for precise determination of sulfur and other elemental concentrations in various materials like petroleum products, coal, chemicals, and environmental samples.

Aggressive Chemical Sample Preparation

Utilized in laboratories for sample digestion, dissolution, or synthesis processes involving strong acids, alkalis, or other corrosive reagents, where the high purity and chemical inertness of quartz are essential to prevent contamination and ensure analytical accuracy.

Yes, absolutely. We specialize in custom fabrication. Please provide your required dimensions, drawings, or specific design needs, and our team will work with you to create a quartz solution tailored to your exact application.

Our high-purity fused quartz boats and sample holders are designed to withstand continuous operating temperatures up to 1200°C, making them suitable for most high-temperature analytical and experimental procedures.

They are made from ultra-high purity SiO2 (≥99.99%), which ensures minimal interference or contamination of your samples. Their inertness to most chemicals and non-porous structure also prevents carry-over or absorption, leading to highly accurate and reproducible results.

Frequently asked questions

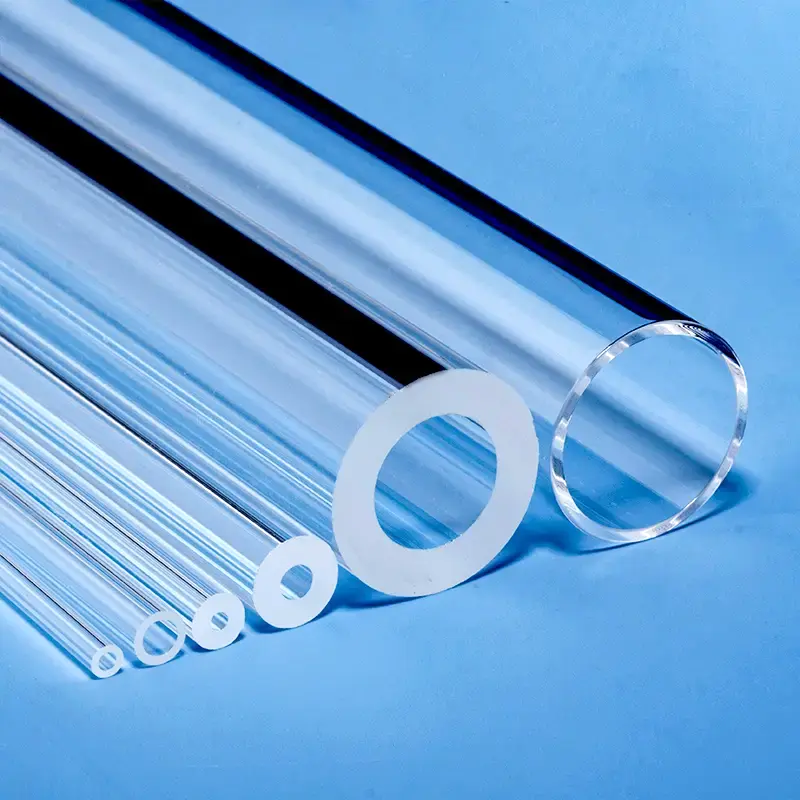

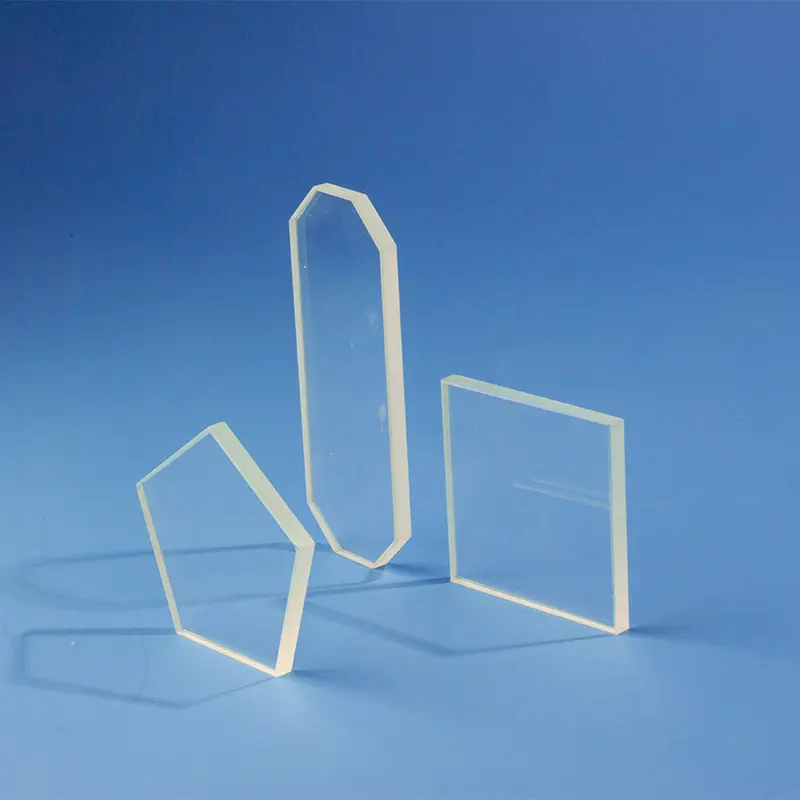

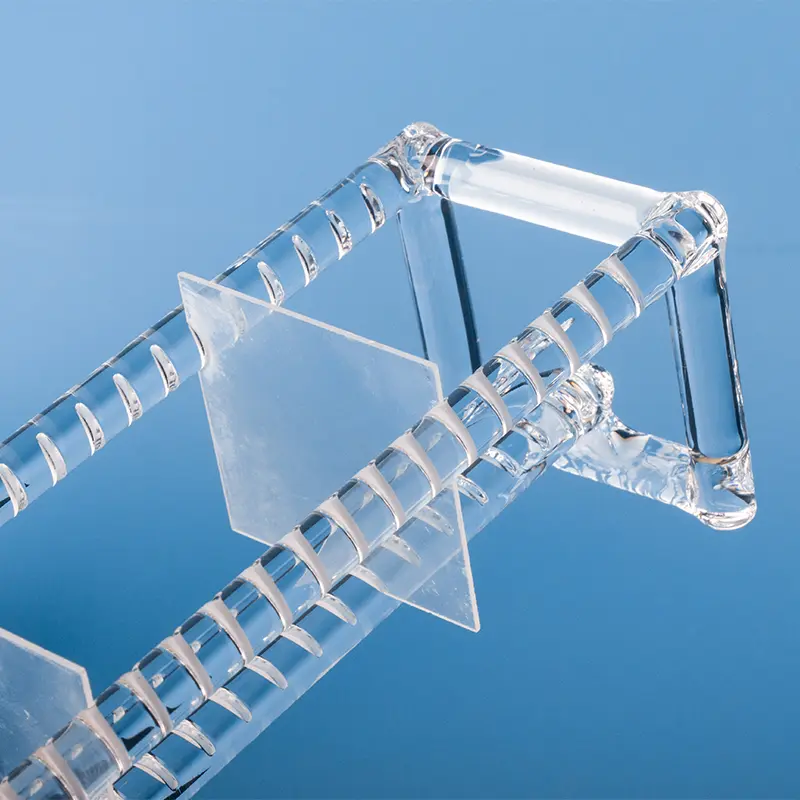

We specialize in the end-to-end manufacturing of high-purity quartz glass components. Our core product lines include:

Quartz Tubing & Rods: A wide range of diameters and specifications.

Quartz Plates & Discs: Precision-cut and polished for optical and industrial use.

Quartz Labware: A full suite of standard and custom glassware, including beakers, flasks, and boats.

Semiconductor-Grade Quartz: High-purity components like process tubes and carriers for semiconductor fabrication.

Custom Fabricated Components: We can produce complex parts tailored to your unique designs and specifications.

Yes. Custom fabrication is at the core of our business. With over a decade of specialized experience, we partner with companies to provide expert OEM/ODM services. Our capabilities include welding, grinding, drilling, polishing, bending, and other precision processing techniques to create components that meet your exact requirements.

Quality is paramount in our manufacturing process. We are an ISO 9001:2015 certified manufacturer, ensuring that our processes meet international quality management standards.Our products also undergo rigorous SGS testing for purity and performance. We use high-purity raw materials (up to 99.998% SiO2) to produce fused quartz and fused silica products with exceptional thermal stability, high-temperature resistance, and chemical inertness.

We've streamlined our process to be as efficient as possible:

Submit Your RFQ: Send us your technical drawings, specifications, and requirements via our website contact form or email.

Rapid Response: You can expect an initial response within minutes and detailed communication within half an hour.

Design & Proposal: We will deliver a detailed design proposal and a competitive quote within 24 hours.

Prototyping & Production: Upon approval, we move swiftly from prototyping to full-scale production to meet your deadlines.

Partnering with Aoxin Quartz offers several key advantages:

Proven Expertise: With 10+ years in the industry, we have the technical knowledge to tackle complex challenges.

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

Competitive Value: Located in a major quartz production hub, we leverage an efficient supply chain and advanced manufacturing to offer exceptional quality at a competitive price point.

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.