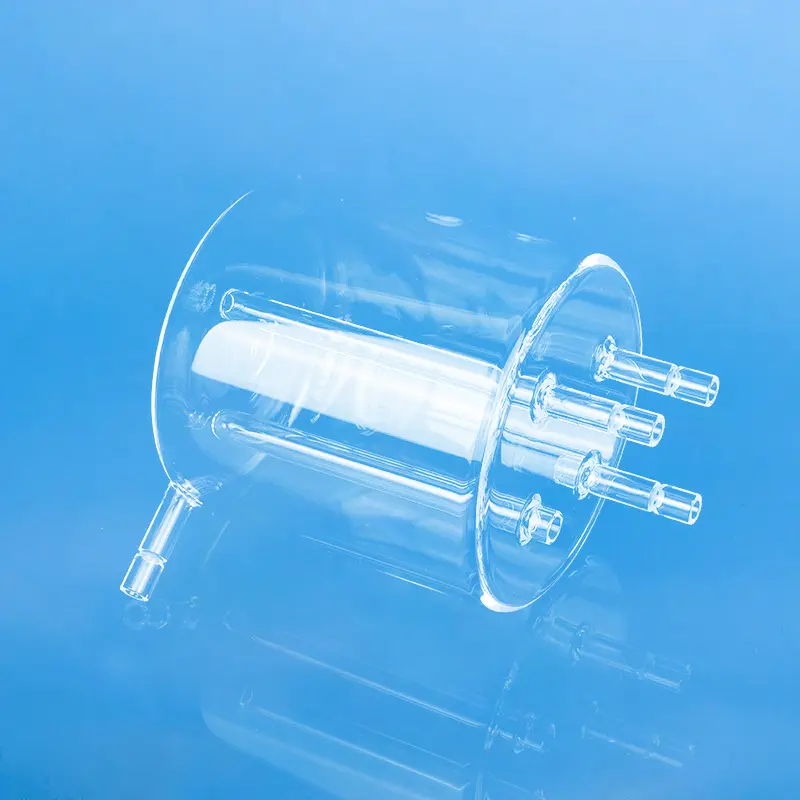

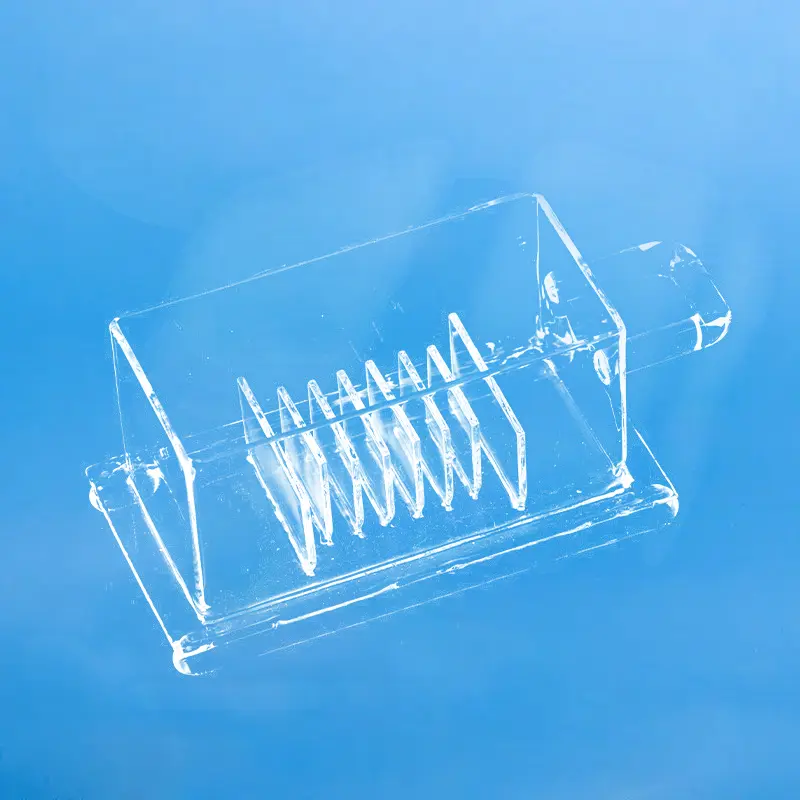

A quartz waste liquid bottle is a specialized container widely used in laboratories and industrial production for the collection and disposal of chemical waste liquids.

| Property Content | Property Values |

|---|---|

| SiO2 | 99.99% |

| Density | 2.2×10³ kg/cm³ |

| Hardness | 5.5 - 6.5 Mohs' Scale 570 KHN 100 |

| Tensile Strength | 4.8×10⁷ Pa (N/mm2) (7000 psi) |

| Compression Strength | >1.1×10⁹ Pa (160,000 psi) |

| Coefficient of Thermal Expansion | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| Thermal Conductivity | 1.4 W/m·°C |

| Specific Heat | 670 J/kg·°C |

| Softening Point | 1730°C (3146°F) |

| Annealing Point | 1210°C (2210°F) |

| Strain Point | 1120°C (2048°F) |

| Work Temperature | 1200°C (2192°F) |

| Electrical Resistivity | 7×10⁷ ohm cm (350°C) |

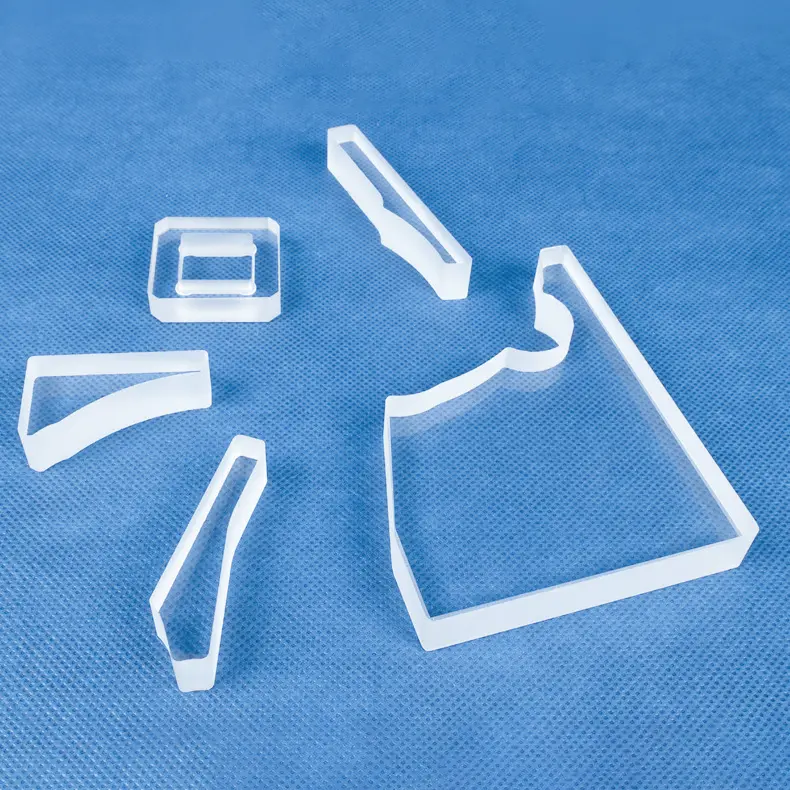

| Size | Customized |

| Logo | Customized Logo Accept |

High Purity

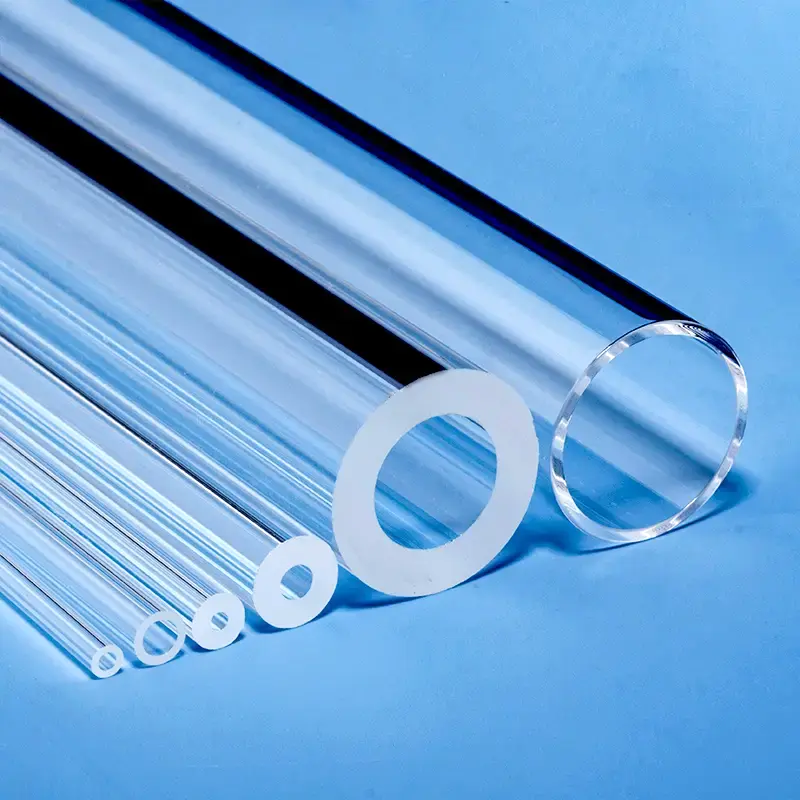

Quartz waste liquid bottles are typically made from high-purity quartz, primarily composed of silicon dioxide (SiO2). This high-purity material ensures stability and reliability in various chemical environments.

High-Temperature Resistance

Quartz material has a high softening point, typically remaining stable under high-temperature conditions. This allows quartz waste liquid bottles to withstand the processing of high-temperature waste liquids.

Corrosion Resistance

Quartz waste liquid bottles exhibit excellent corrosion resistance, capable of withstanding erosion from many strong acids, strong bases, and organic solvents. This ensures the waste liquid does not damage the container during processing.

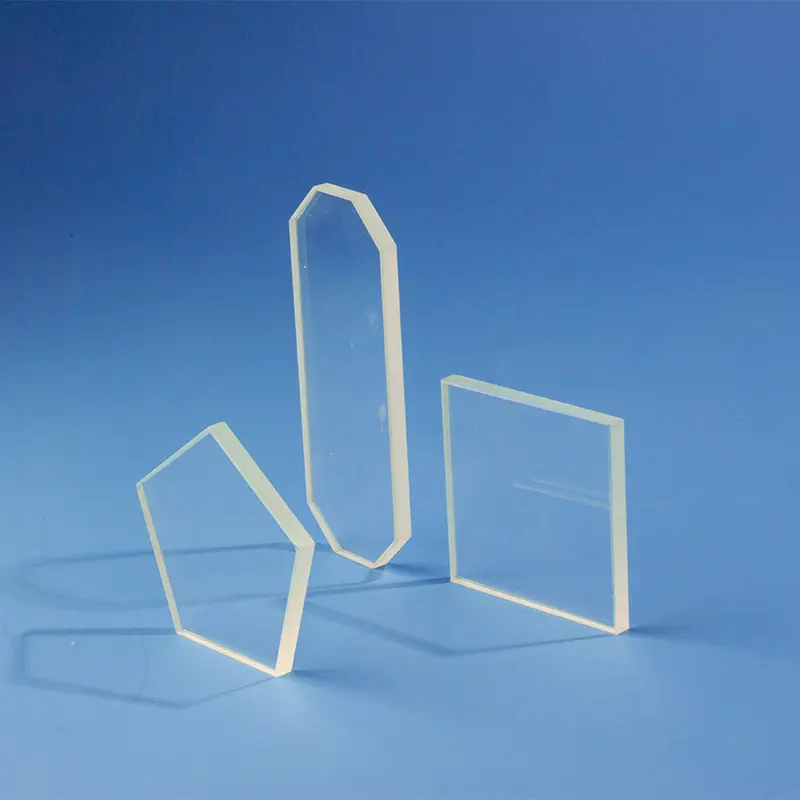

High Transparency

The high transparency of quartz waste liquid bottles makes it easy to observe the state and color of the waste liquid, helping to assess the effectiveness of waste processing.

Application Scenario

Quartz waste liquid bottles can hold various hazardous liquids such as high-concentration acids, strong bases, and organic solvents because quartz glass has extremely high chemical stability and almost does not react with most chemical substances.

Except for hydrofluoric acid and hot phosphoric acid, quartz glass can maintain its performance and integrity in a variety of chemical environments, including resistance to erosion by various acids, aqua regia, neutral salts, sulfur, and carbon.

Quartz waste liquid bottles are widely used in chemical laboratories as high-temperature reaction containers capable of withstanding temperatures above 1000℃. Additionally, they are used in chemical analysis experiments, such as containers for holding solutions being tested and as sample containers in high-precision analytical instruments like mass spectrometers.

Transparency: Quartz waste liquid bottles have high transparency, which makes it easy to observe the waste liquid inside both the unfiltered area and the filtered area during filtration and precipitation.

Thermal Conductivity: Quartz waste liquid bottles have low thermal conductivity, approximately 1.4 W/(m·K), which enables them to effectively insulate and retain heat in high-temperature environments, providing excellent thermal isolation.

Frequently asked questions

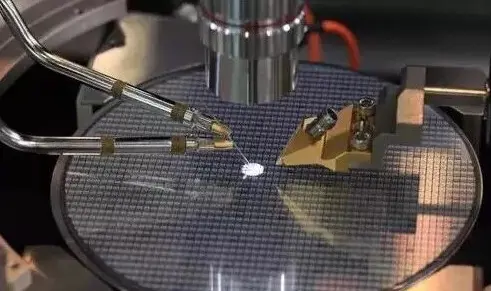

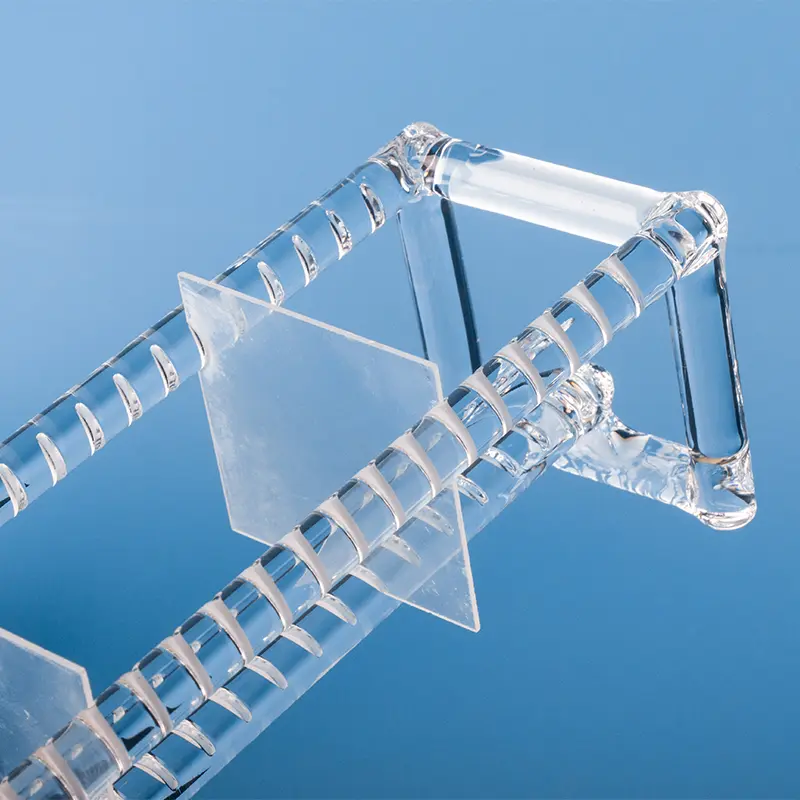

Quartz glass is a hard and brittle material with excellent physical and chemical properties, extremely high mechanical hardness, good electrical insulation, high temperature and corrosion resistance, low and stable delay performance, good light transmittance, etc. It is widely used in semiconductors, optics, electricity, chemistry, aerospace, automobiles and other fields. Hard and brittle materials are difficult to process, and many fields urgently need cutting processes with small edge collapse, less material loss, low cross-section roughness, and a wide cutting thickness range. The traditional cutting method of quartz glass is mechanical cutting, that is, wheel cutting. Non-traditional cutting methods include water jet cutting, electrochemical discharge wire cutting, continuous laser cutting, etc. Mechanical cutting has low cost, but the contact between the wheel and the material causes large tool wear, and the material is easily contaminated by the tool. Quartz glass is prone to edge collapse, microcracks, and residual stress, which affects the strength and performance of the material! It is difficult to achieve curve cutting and requires post-processing, such as grinding and polishing. Laser cutting does not directly contact the material, has no contact stress, and can perform complex curve cutting. Picosecond laser has the advantages of small spot diameter, high precision, short action time with the material, and small action area, and is suitable for the processing of hard and brittle materials.

。