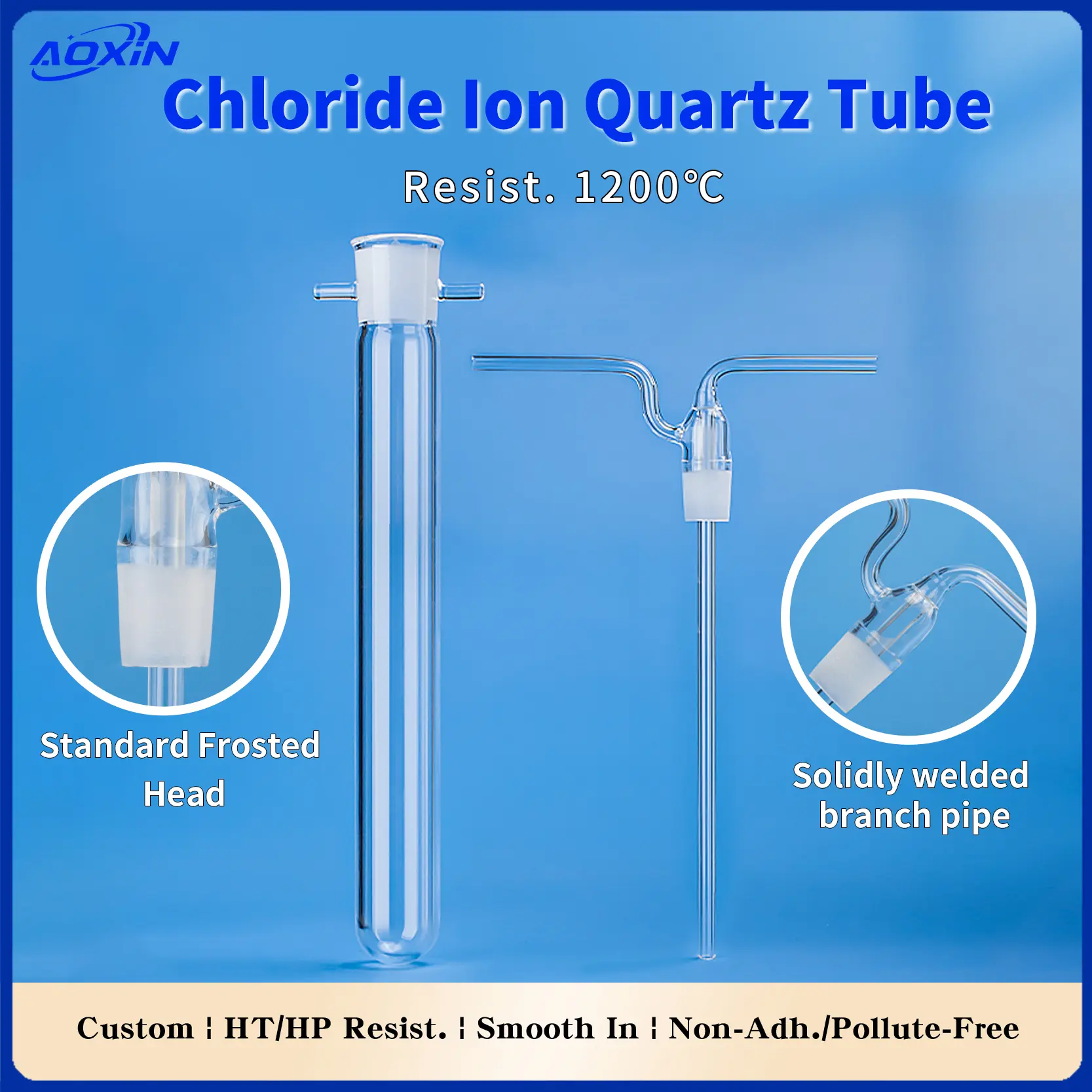

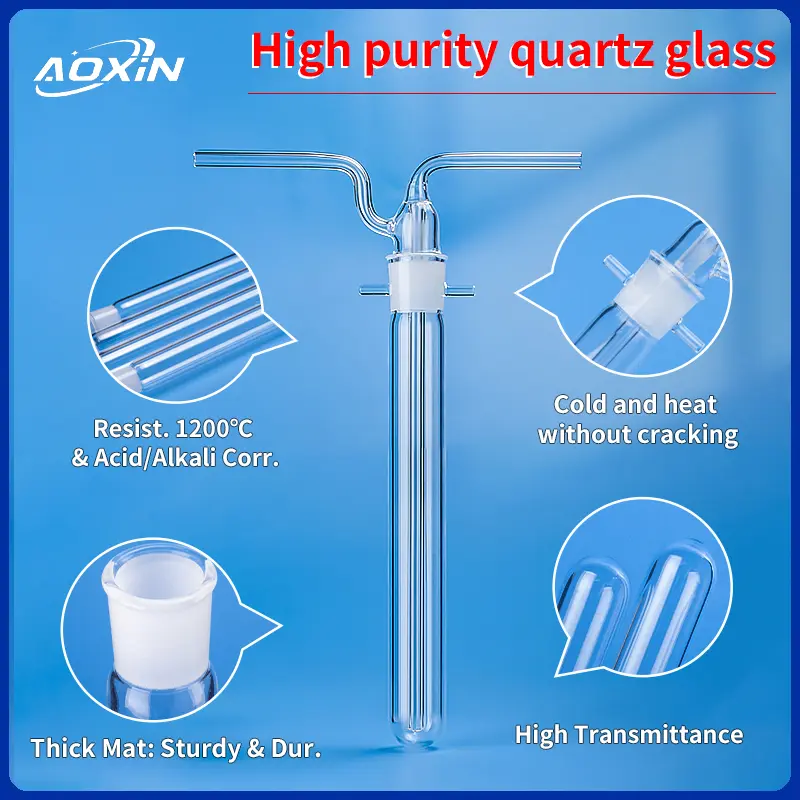

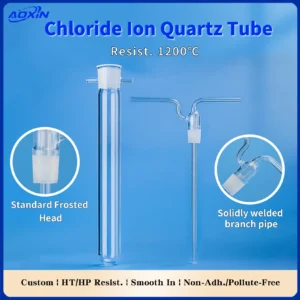

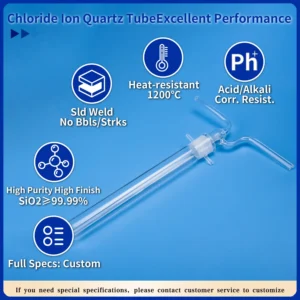

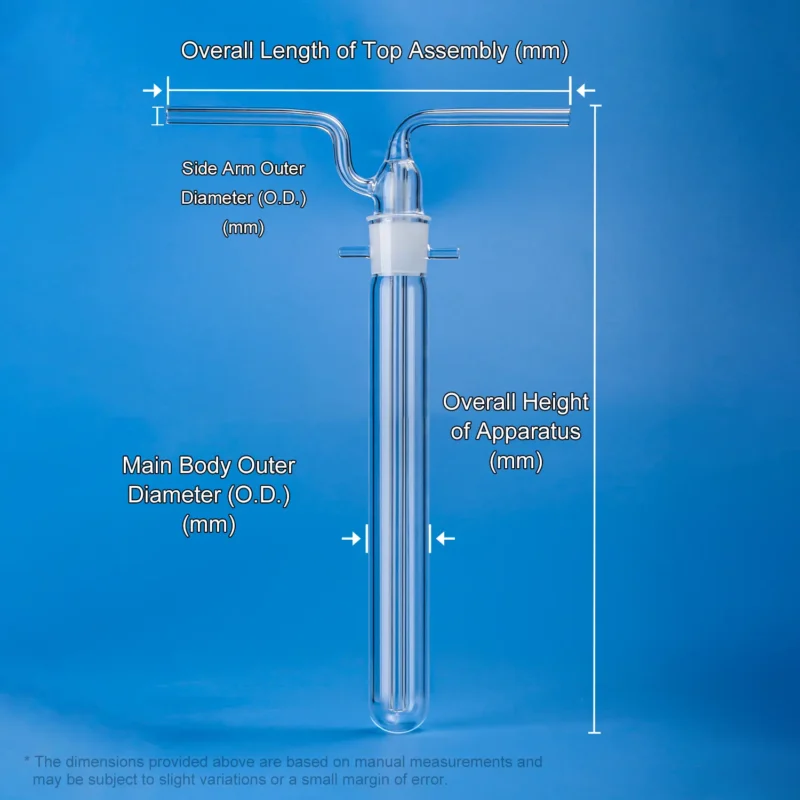

Our specialized Chloride Ion Quartz Tube is meticulously engineered for the most demanding halogen analysis and high-purity chemical reactions. Crafted from 99.99% high-purity fused silica, this reaction tube is highly resistant to extreme temperatures (up to 1200°C) and aggressive corrosive media, ensuring uncompromised sample integrity. Featuring a standard frosted head for secure connections and a solidly welded branch pipe for versatile applications, it offers superior performance for precise chloride ion detection, organic halogen combustion, and other sensitive analytical procedures. Full customization is available to meet your exact laboratory or industrial specifications.

Remarks:

- ayment method: By wire transfer or advance payment, depending on the quantity of the order.

- Delivery time: According to the order quantity.

- Transportation method: Sea freight or air freight, depending on the customer.

| Property Content | Property Values |

|---|---|

| SiO2 | 99.99% |

| Density | 2.2×10³ kg/cm³ |

| Hardness | 5.5 - 6.5 Mohs' Scale 570 KHN 100 |

| Tensile Strength | 4.8×10⁷ Pa (N/mm2) (7000 psi) |

| Compression Strength | >1.1×10⁹ Pa (160,000 psi) |

| Coefficient of Thermal Expansion | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| Thermal Conductivity | 1.4 W/m·°C |

| Specific Heat | 670 J/kg·°C |

| Softening Point | 1730°C (3146°F) |

| Annealing Point | 1210°C (2210°F) |

| Strain Point | 1120°C (2048°F) |

| Work Temperature | 1200°C (2192°F) |

| Electrical Resistivity | 7×10⁷ ohm cm (350°C) |

| Size | Customized |

| Logo | Customized Logo Accept |

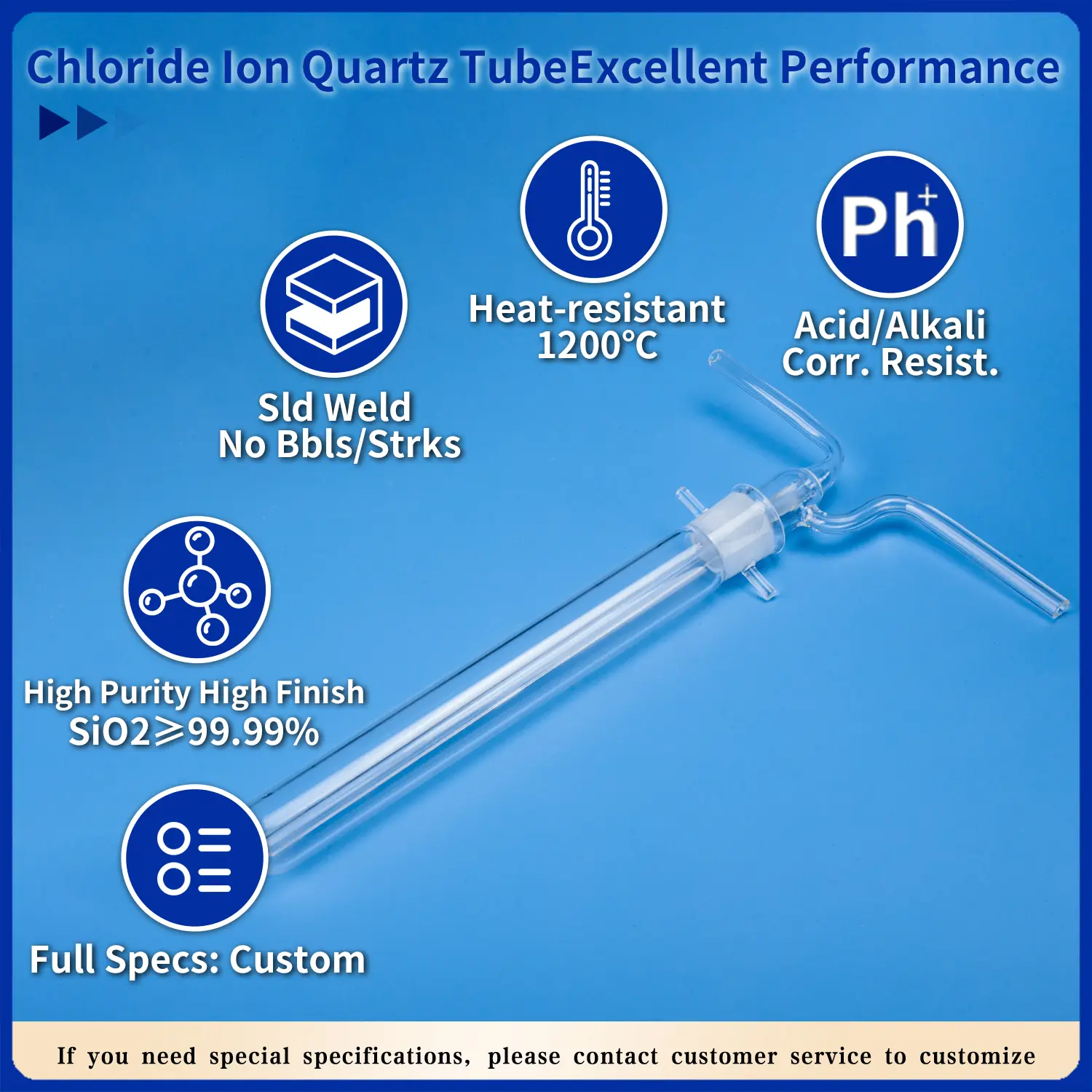

Superior Performance in High-Temperature Halogen Combustion

Designed to resist temperatures up to 1200°C, it is perfectly suited for combustion methods used in the analysis of halogens (including chloride) in various samples, providing a stable and reliable vessel for thermal decomposition without degradation.

Exceptional Corrosion Resistance to Aggressive Reagents

Its inherent inertness to most acids and alkalis allows it to safely handle corrosive reagents often involved in chloride or halogen extraction and reaction processes, ensuring the integrity of the sample and the longevity of the apparatus.

Unmatched Purity for Trace Analysis

Fabricated from 99.99% high-purity fused silica, this tube ensures minimal material leaching or contamination, which is critical for highly sensitive applications like trace chloride ion detection or elemental analysis where accuracy depends on the purity of the reaction environment.

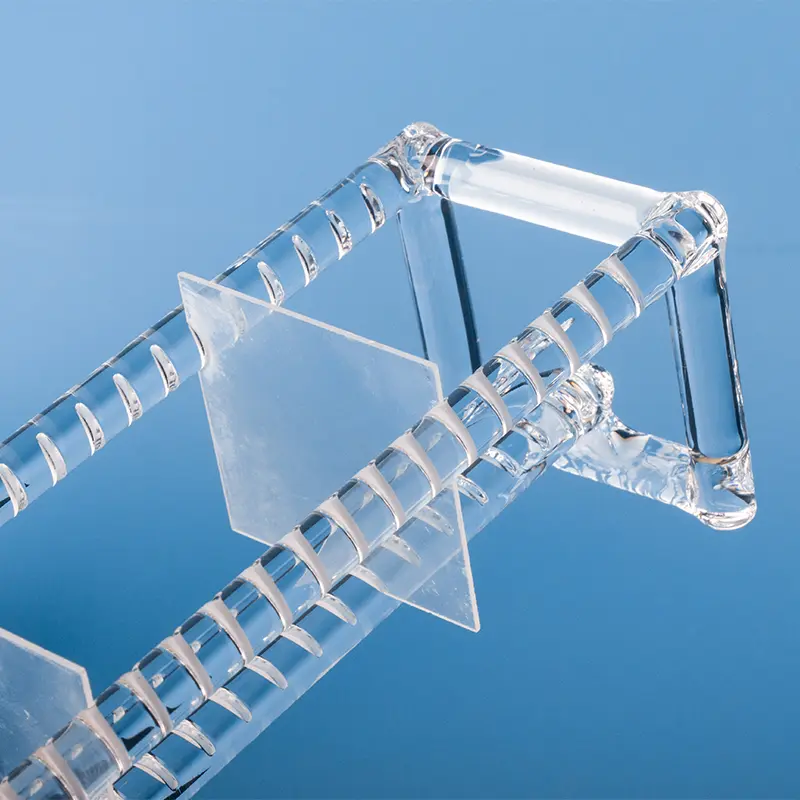

Integrated Design for Secure & Efficient Analysis

Featuring a standard frosted head for secure connections to other glassware (e.g., absorption solutions or gas inlets/outlets) and a solidly welded branch pipe, this design ensures leak-free operation and streamlined setup for complex analytical procedures.

Application Scenario

Chloride Ion & Halogen Content Analysis

This tube is specifically designed for the precise determination of chloride ions and other halogen content in various samples (e.g., water, organic compounds, polymers, environmental samples) through high-temperature combustion or reaction methods where the sample is decomposed and halogens are captured.

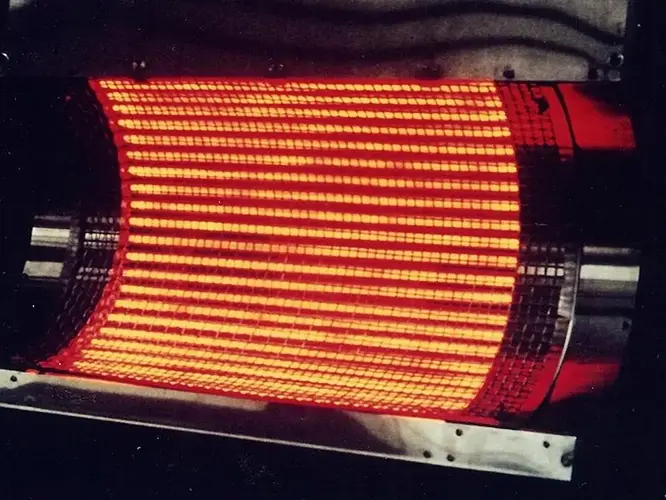

Combustion Analysis Systems (e.g., A/O/X analysis)

It serves as a critical component in combustion furnaces for analytical techniques like AOX (Adsorbable Organic Halogens) or total organic halogen (TOX) analysis, where samples are combusted at high temperatures, and the resulting halogen compounds are absorbed and quantified.

High-Purity Chemical Reactions under Corrosive or High-Temperature Conditions

Beyond specific halogen analysis, its high purity, heat resistance, and inertness make it suitable for general laboratory or industrial chemical reactions involving corrosive gases or liquids at elevated temperatures where standard glass would fail or contaminate the reaction.

Material Science and Environmental Monitoring

Utilized in research and quality control to analyze halogen impurities in new materials, electronic components, or plastics, and for environmental monitoring applications requiring the decomposition and analysis of halogenated organic pollutants in air, water, or soil samples.

Handle with care

Quartz glass products are made from valuable materials and must be handled gently to avoid collisions and falls.

Regular maintenance

The maintenance of quartz tubes must be performed regularly to ensure their long-term stable performance. Regularly check the connections, fixings, and mechanical vibrations of the quartz tubes to prevent abnormalities. The exterior of the quartz tubes is prone to contamination from dust and moisture, so they should be cleaned regularly.

Storage environmen

When storing quartz tubes, care should be taken to avoid exposure to mechanical vibrations, shocks, and excessively high temperatures. They should be kept in a dry, cool, and well-ventilated place, avoiding direct sunlight and high-temperature environments.

This quartz tube is ideal for halogen analysis (including chloride) due to its extremely high purity (minimizing contamination for trace analysis), exceptional heat resistance (critical for combustion methods), and superior inertness to corrosive halogen-containing gases. While primarily designed for halogens, its robust properties also make it suitable for high-temperature reactions or analyses of other elements where a highly inert, non-contaminating, and heat-resistant vessel is required.

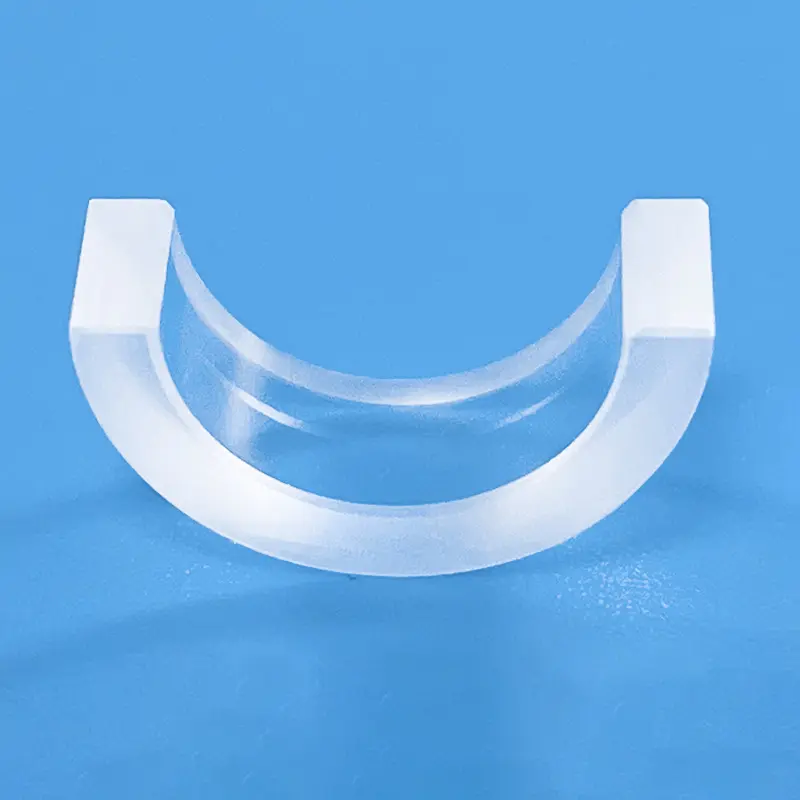

Our Chloride Ion Quartz Tube is designed for stable operating temperatures up to 1200°C. Made from fused silica, it exhibits excellent thermal shock resistance, meaning it can withstand rapid heating and cooling cycles without cracking, which is a common requirement in combustion or high-temperature reaction processes.

We offer both standard ground glass joint sizes (e.g., 19/26, 24/40) and can fully customize the dimensions, angles, and types of branch pipes and joints to integrate seamlessly with your existing analytical equipment or specific experimental setups. Please provide your detailed technical drawings or requirements for a custom solution.

Frequently asked questions

We specialize in the end-to-end manufacturing of high-purity quartz glass components. Our core product lines include:

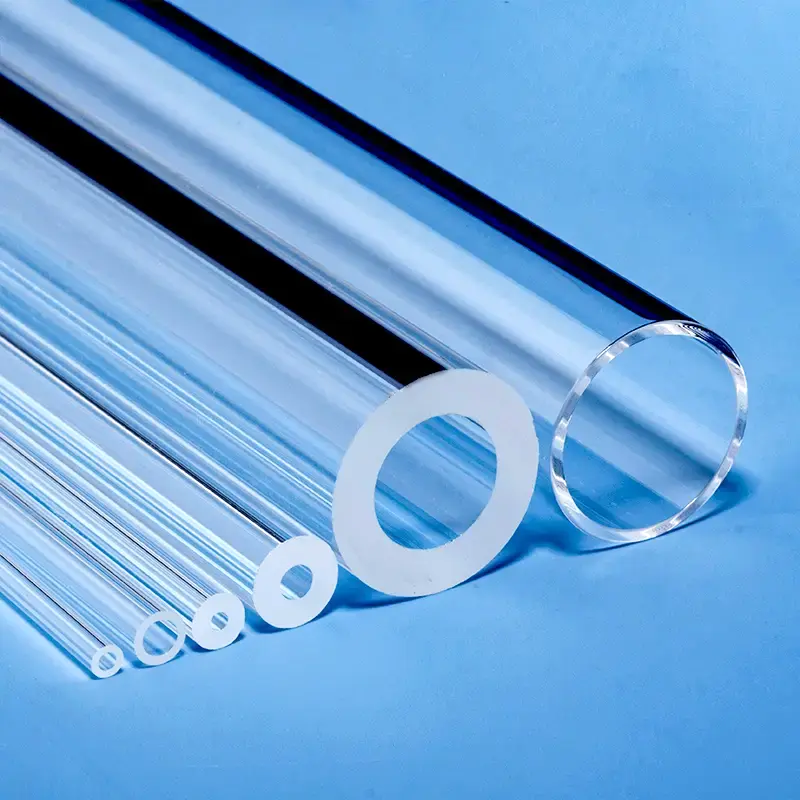

Quartz Tubing & Rods: A wide range of diameters and specifications.

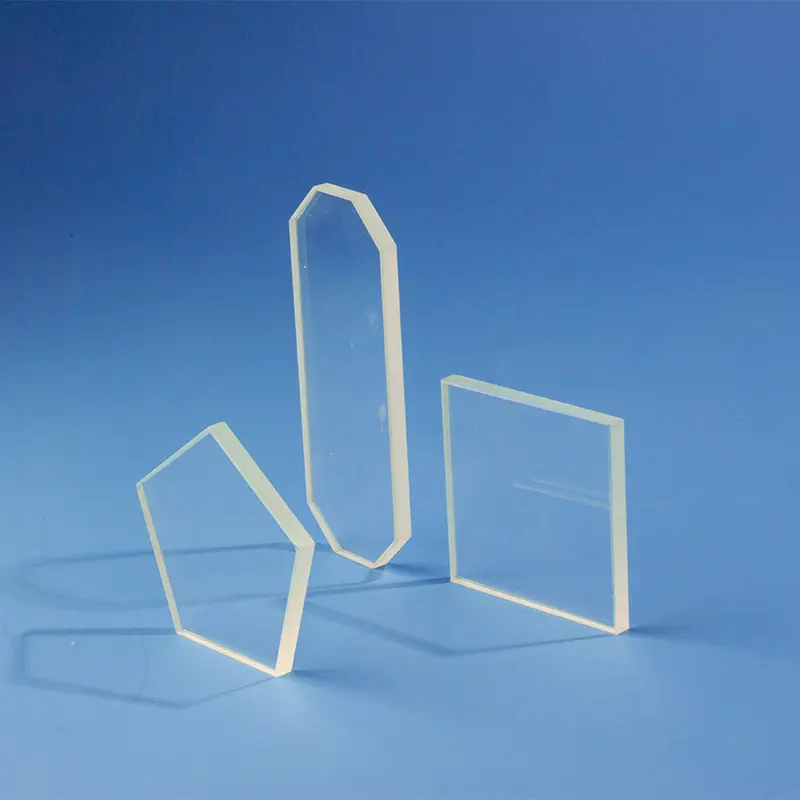

Quartz Plates & Discs: Precision-cut and polished for optical and industrial use.

Quartz Labware: A full suite of standard and custom glassware, including beakers, flasks, and boats.

Semiconductor-Grade Quartz: High-purity components like process tubes and carriers for semiconductor fabrication.

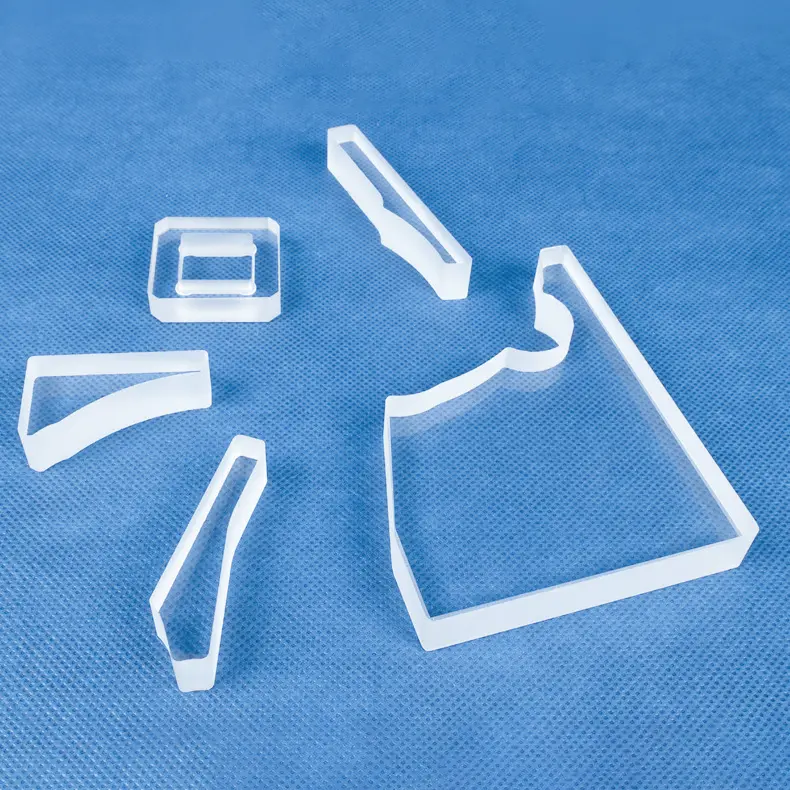

Custom Fabricated Components: We can produce complex parts tailored to your unique designs and specifications.

Yes. Custom fabrication is at the core of our business. With over a decade of specialized experience, we partner with companies to provide expert OEM/ODM services. Our capabilities include welding, grinding, drilling, polishing, bending, and other precision processing techniques to create components that meet your exact requirements.

Quality is paramount in our manufacturing process. We are an ISO 9001:2015 certified manufacturer, ensuring that our processes meet international quality management standards.Our products also undergo rigorous SGS testing for purity and performance. We use high-purity raw materials (up to 99.998% SiO2) to produce fused quartz and fused silica products with exceptional thermal stability, high-temperature resistance, and chemical inertness.

We've streamlined our process to be as efficient as possible:

Submit Your RFQ: Send us your technical drawings, specifications, and requirements via our website contact form or email.

Rapid Response: You can expect an initial response within minutes and detailed communication within half an hour.

Design & Proposal: We will deliver a detailed design proposal and a competitive quote within 24 hours.

Prototyping & Production: Upon approval, we move swiftly from prototyping to full-scale production to meet your deadlines.

Partnering with Aoxin Quartz offers several key advantages:

Proven Expertise: With 10+ years in the industry, we have the technical knowledge to tackle complex challenges.

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

Competitive Value: Located in a major quartz production hub, we leverage an efficient supply chain and advanced manufacturing to offer exceptional quality at a competitive price point.

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.