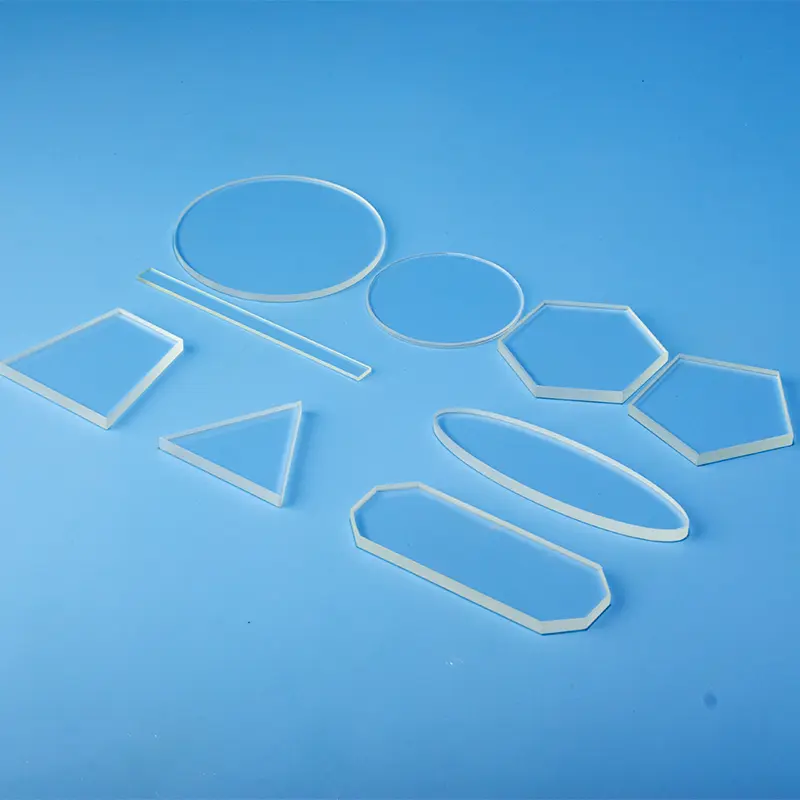

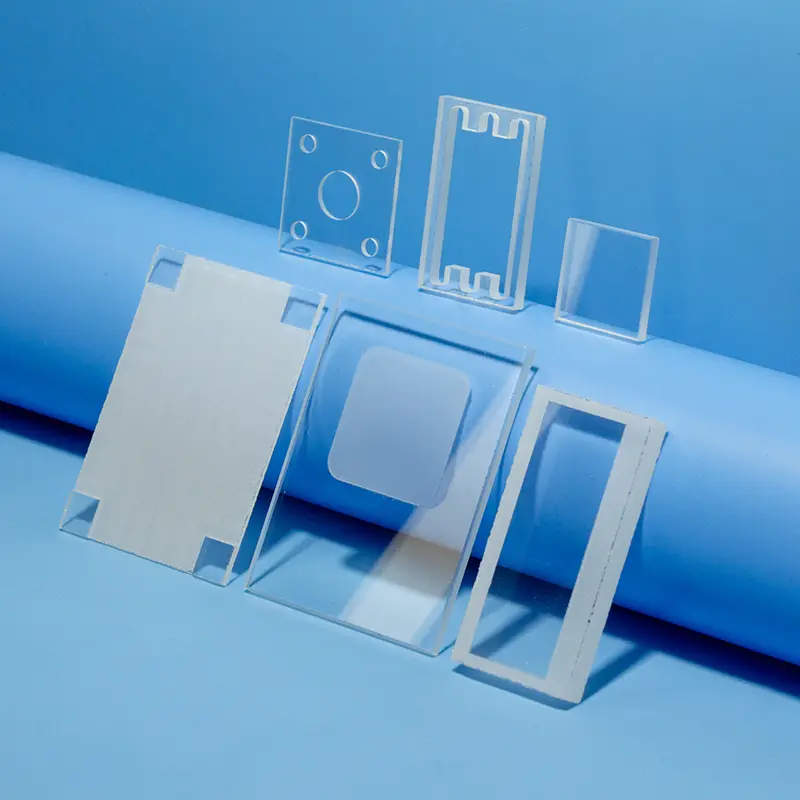

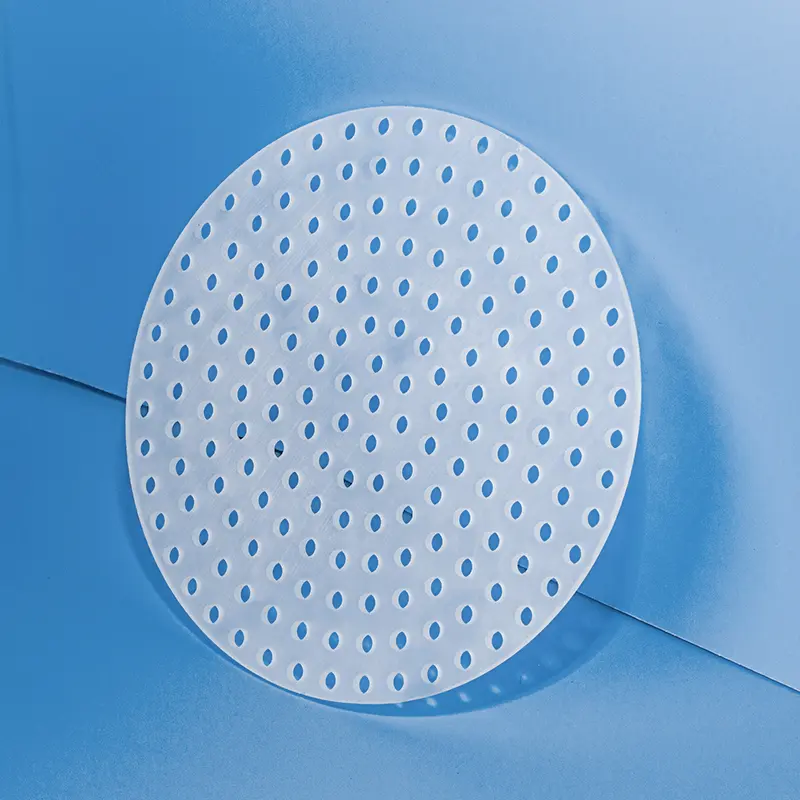

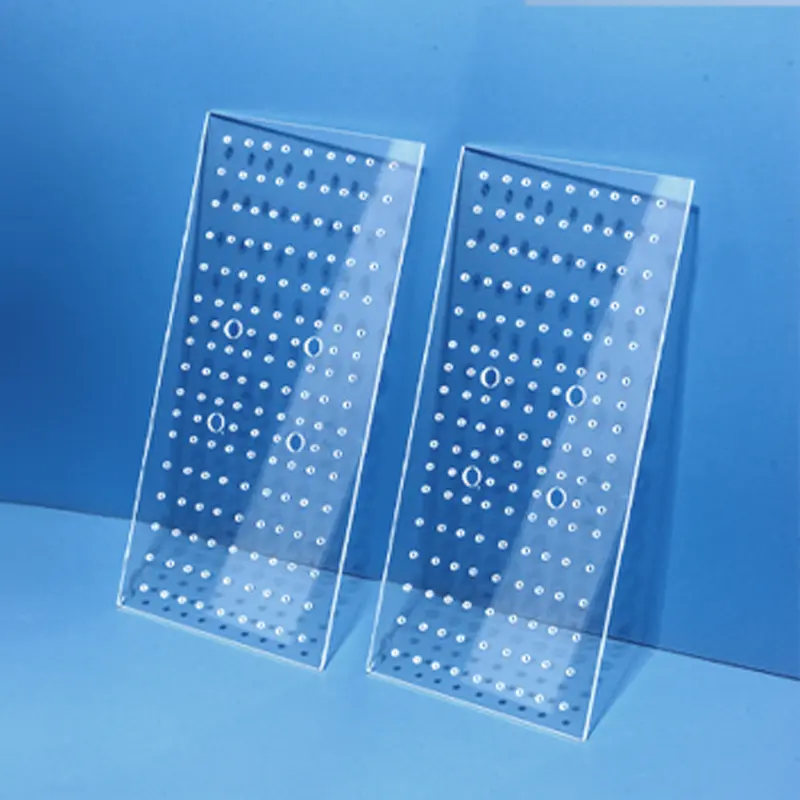

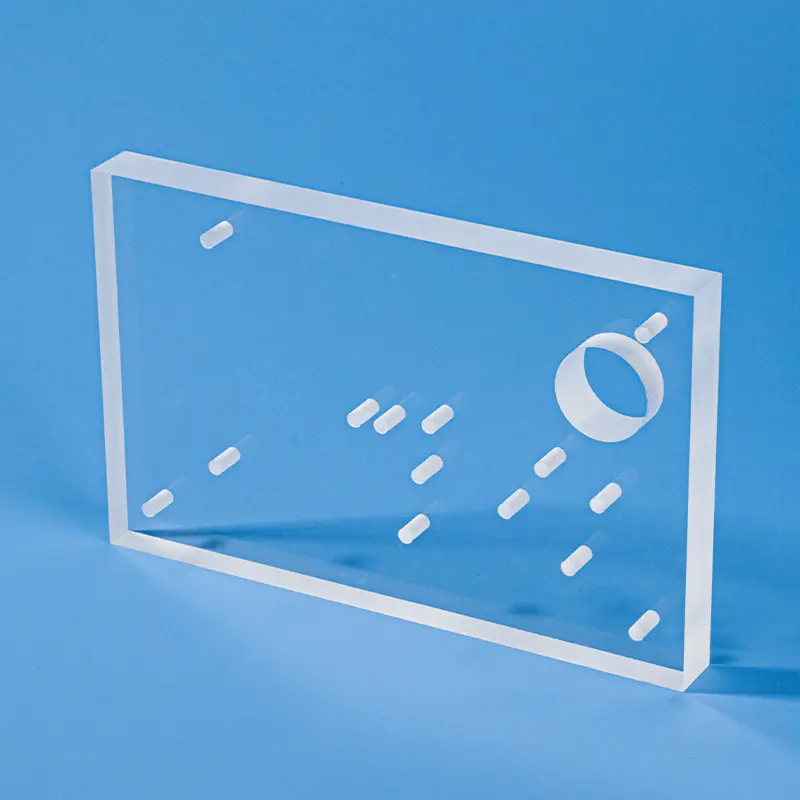

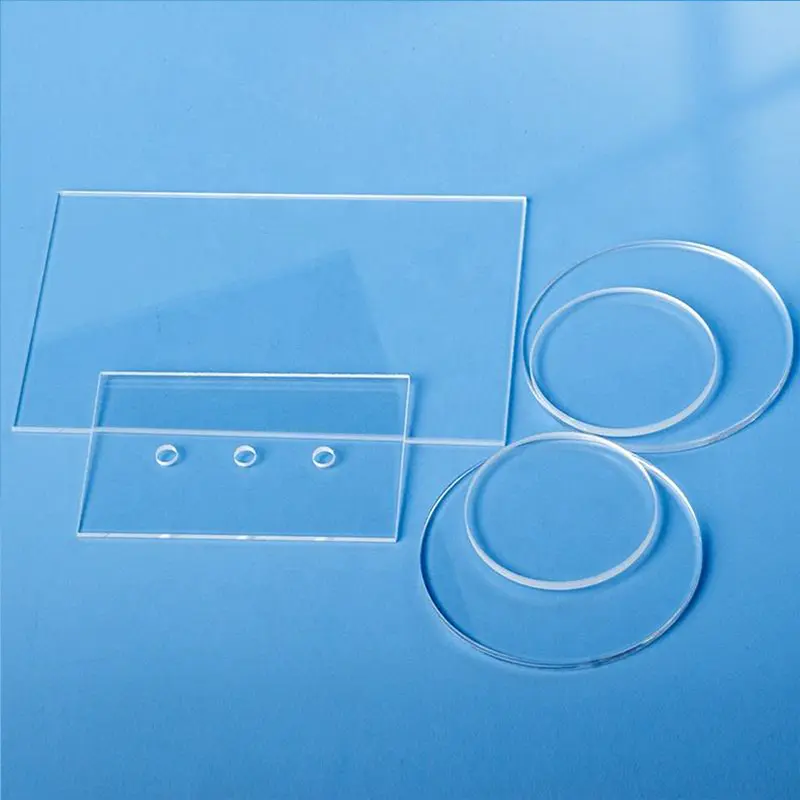

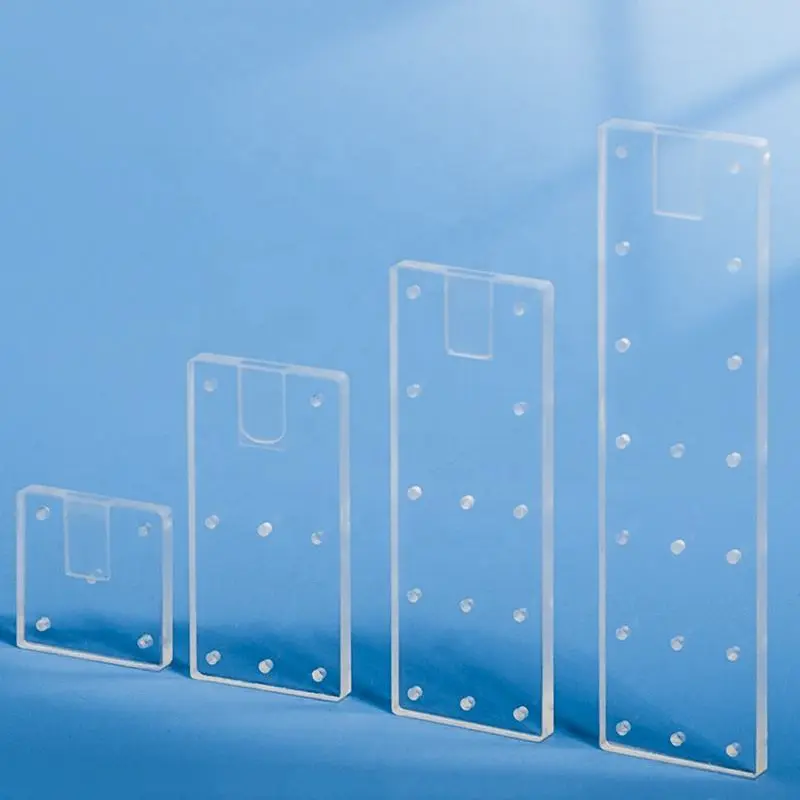

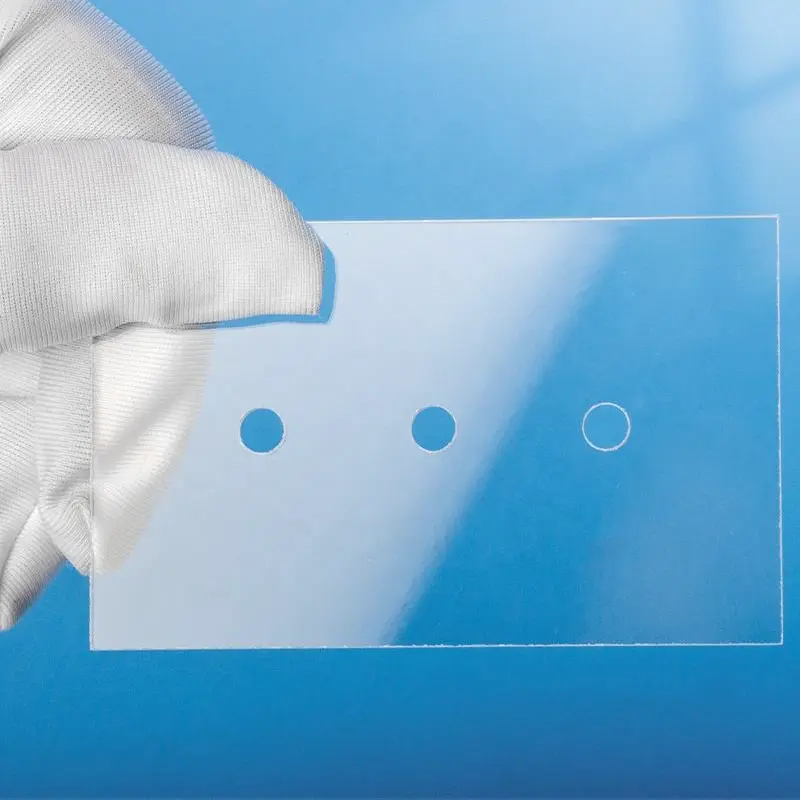

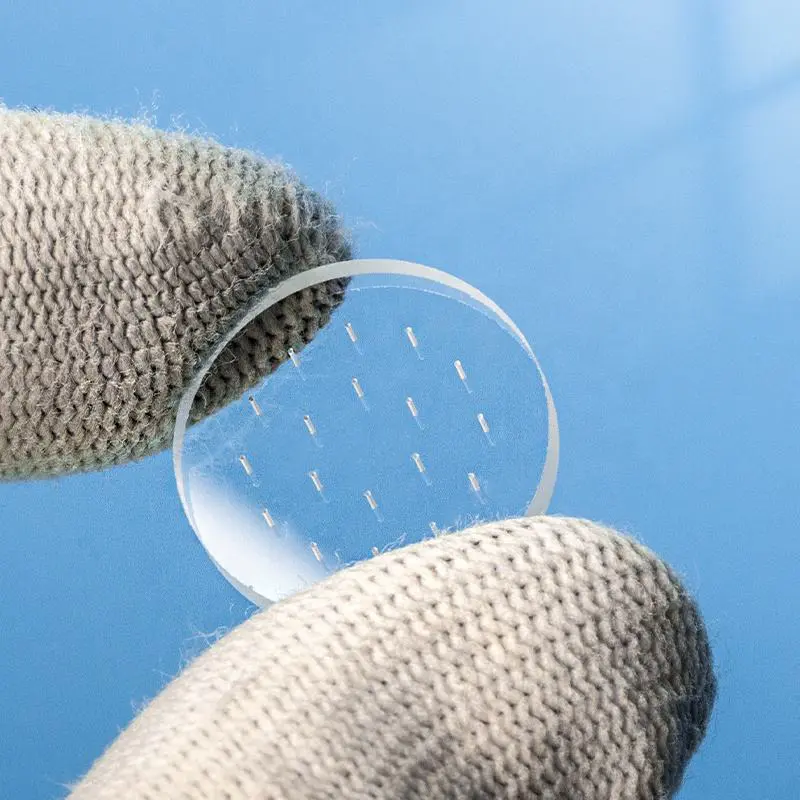

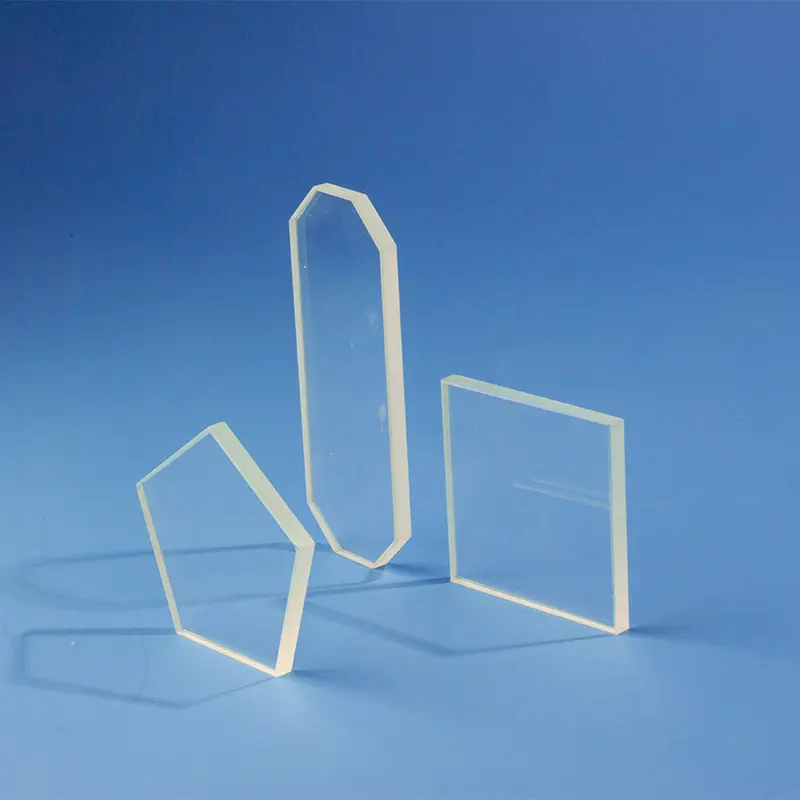

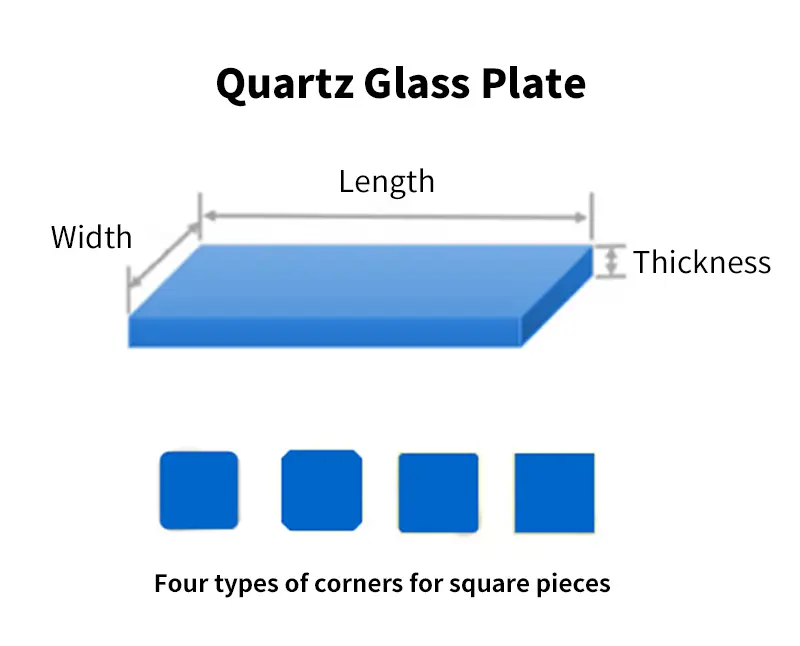

Our quartz glass plates are precision-engineered components made from high-purity fused silica, offering exceptional transparency and optical clarity. These robust sheets boast superior resistance to high temperatures and harsh chemicals, alongside a very low thermal expansion coefficient. With excellent electrical insulation properties, our quartz plates are indispensable for demanding applications in optical fiber communication, semiconductor manufacturing, and medical equipment. Available in a wide range of standard dimensions and thicknesses to suit your specific technical requirements.

| Length | Width | Thickness |

|---|---|---|

| 5mm | 5mm | 1mm |

| 10mm | 10mm | 0.5mm |

| 10mm | 10mm | 1mm |

| 10mm | 10mm | 2mm |

| 12mm | 12mm | 1mm |

| 15mm | 15mm | 0.5mm |

| 15mm | 15mm | 1mm |

| 15mm | 15mm | 2mm |

| 15mm | 15mm | 3mm |

| 20mm | 20mm | 0.5mm |

| 20mm | 20mm | 1mm |

| 20mm | 20mm | 2mm |

| 20mm | 20mm | 3mm |

| 25mm | 25mm | 0.5mm |

| 25mm | 25mm | 1mm |

| 25mm | 25mm | 2mm |

| 25mm | 25mm | 3mm |

| 30mm | 30mm | 0.5mm |

| 30mm | 30mm | 1mm |

| 30mm | 30mm | 2mm |

| 30mm | 30mm | 3mm |

| 35mm | 35mm | 1mm |

| 35mm | 35mm | 2mm |

| 35mm | 35mm | 3mm |

| 40mm | 40mm | 0.5mm |

| 40mm | 40mm | 1mm |

| 40mm | 40mm | 2mm |

| 40mm | 40mm | 3mm |

| 45mm | 45mm | 1mm |

| 45mm | 12mm | 1mm |

| 45mm | 12mm | 2mm |

| 35mm | 35mm | 2mm |

| 50mm | 50mm | 0.5mm |

| 50mm | 50mm | 1mm |

| 50mm | 50mm | 2mm |

| 50mm | 50mm | 3mm |

| 50mm | 50mm | 4mm |

| 50mm | 50mm | 5mm |

| 60mm | 60mm | 1mm |

| 60mm | 60mm | 2mm |

| 60mm | 60mm | 3mm |

| 70mm | 70mm | 2mm |

| 70mm | 70mm | 3mm |

| 70mm | 70mm | 5mm |

| 75mm | 25mm | 0.5mm |

| 75mm | 25mm | 1mm |

| 75mm | 25mm | 2mm |

| 80mm | 80mm | 1mm |

| 80mm | 80mm | 2mm |

| 80mm | 80mm | 3mm |

| 80mm | 80mm | 4mm |

| 100mm | 100mm | 1mm |

| 100mm | 100mm | 1.5mm |

| 100mm | 100mm | 2mm |

| 100mm | 100mm | 3mm |

| 100mm | 100mm | 5mm |

| 100mm | 100mm | 0.5mm |

| 100mm | 100mm | 1mm |

| 100mm | 100mm | 2mm |

| 100mm | 100mm | 3mm |

| 100mm | 100mm | 5mm |

| 150mm | 150mm | 2mm |

| 150mm | 150mm | 3mm |

| 150mm | 150mm | 5mm |

- ayment method: By wire transfer or advance payment, depending on the quantity of the order.

- Delivery time: According to the order quantity.

- Transportation method: Sea freight or air freight, depending on the customer.

Remarks:

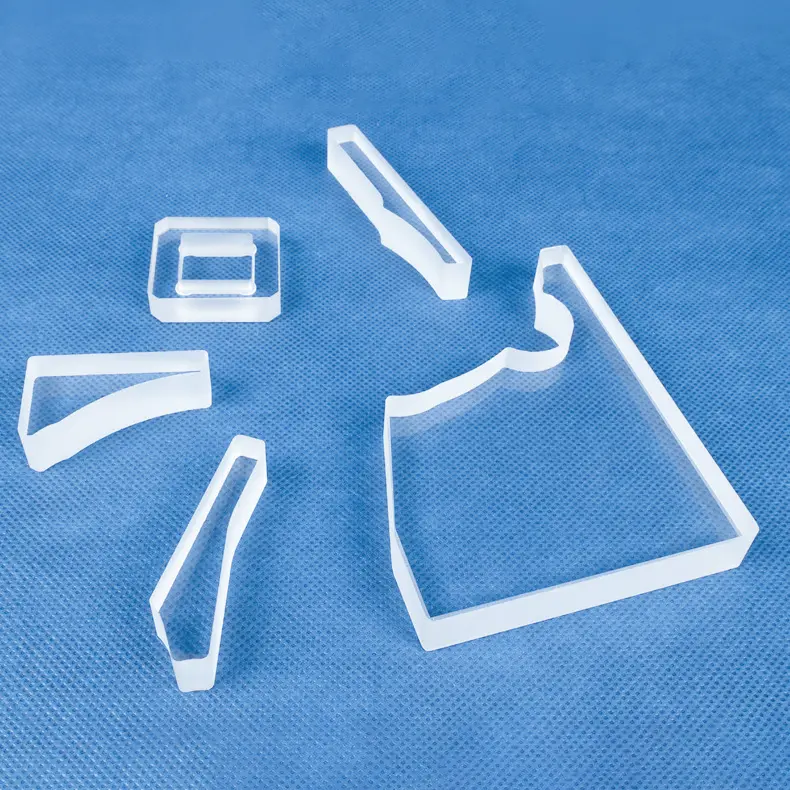

To confirm the order, The following parameters need to be provided: ① Square: length, width, thickness ② Circle: diameter, thickness ③ Accuracy ④ Quantity

| Property Content | Property Values |

|---|---|

| SiO2 | 99.99% |

| Density | 2.2×10³ kg/cm³ |

| Hardness | 5.5 - 6.5 Mohs' Scale 570 KHN 100 |

| Tensile Strength | 4.8×10⁷ Pa (N/mm2) (7000 psi) |

| Compression Strength | >1.1×10⁹ Pa (160,000 psi) |

| Coefficient of Thermal Expansion | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| Thermal Conductivity | 1.4 W/m·°C |

| Specific Heat | 670 J/kg·°C |

| Softening Point | 1730°C (3146°F) |

| Annealing Point | 1210°C (2210°F) |

| Strain Point | 1120°C (2048°F) |

| Work Temperature | 1200°C (2192°F) |

| Electrical Resistivity | 7×10⁷ ohm cm (350°C) |

| Size | Customized |

| Logo | Customized Logo Accept |

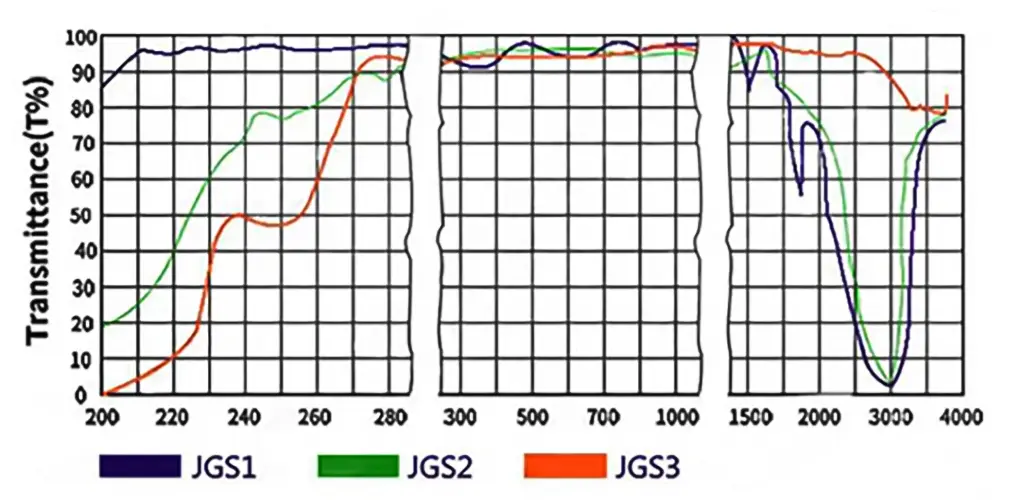

JGS1

Commonly known as UV-grade fused silica, this material exhibits exceptionally low dispersion and very high transmittance in the ultraviolet (UV) spectral range.

JGS2

Similar to JGS1, but may have variations in specific performance parameters such as transmittance and thermal expansion coefficient, depending on the manufacturer’s standards.

JGS3

Typically used in applications requiring higher purity or specialized performance characteristics. Specific performance parameters can vary based on the manufacturer.

Dispersion Characteristics

JGS1 and JGS2 quartz sheets exhibit excellent dispersion properties in the ultraviolet (UV) spectral range, effectively separating UV light of different wavelengths. This makes them ideal for manufacturing high-performance optical components.

Transmittance

All three types of quartz sheets have high transmittance to UV light, especially within specific wavelength ranges. For example, JGS1 has very high transmittance from 185 nm to 2,500 nm. This makes them the preferred materials for manufacturing UV lasers, UV spectrometers, and optical filters.

Chemical Stability

Quartz sheets possess excellent chemical stability and can withstand harsh conditions, including acids, alkalis, and high temperatures. Therefore, they are suitable for manufacturing chemical reactors, high-temperature furnace windows, and chemical analysis instruments.

Low Thermal Expansion Coefficient

These quartz sheets have very low thermal expansion coefficients, exhibiting minimal response to temperature changes. This is crucial for the stability of high-precision optical components.

Application Scenario

Quartz sheets exhibit excellent high-temperature resistance, corrosion resistance, thermal stability, and light transmittance. Its softening point is approximately 1730°C, and it can be used continuously at 1100°C, with short-term usage up to 1450°C. Quartz glass is highly resistant to acids, with the exception of hydrofluoric acid, and demonstrates high resistance to chemical reactions with most other acids. Quartz sheets have a very low thermal expansion coefficient, enabling them to withstand rapid temperature changes without fracturing. They also exhibit good light transmittance across the entire UV to IR spectrum, with a visible light transmittance exceeding 93%.

Based on optical properties, quartz sheets are classified into three categories: far-ultraviolet (FUV) optical quartz glass (JGS1), ultraviolet (UV) optical quartz glass (JGS2), and infrared (IR) optical quartz glass (JGS3). These different types of quartz glass exhibit variations in transparency, absorption band positions, etc., in the UV and visible spectral ranges.

The processing of quartz sheets includes rough processing steps such as raw material sorting, rod bonding, seed crystal cutting, and rounding. This is followed by grinding stages, such as rough grinding, medium grinding, and fine grinding. Afterwards, polishing and cleaning processes are conducted to ensure surface quality and stability of the wafers. Finally, mounting and die-bonding involves fixing the quartz sheets with applied electrodes and applying conductive adhesive to the contact points between the electrodes and metal pads to achieve electrical connection.

Frequently asked questions

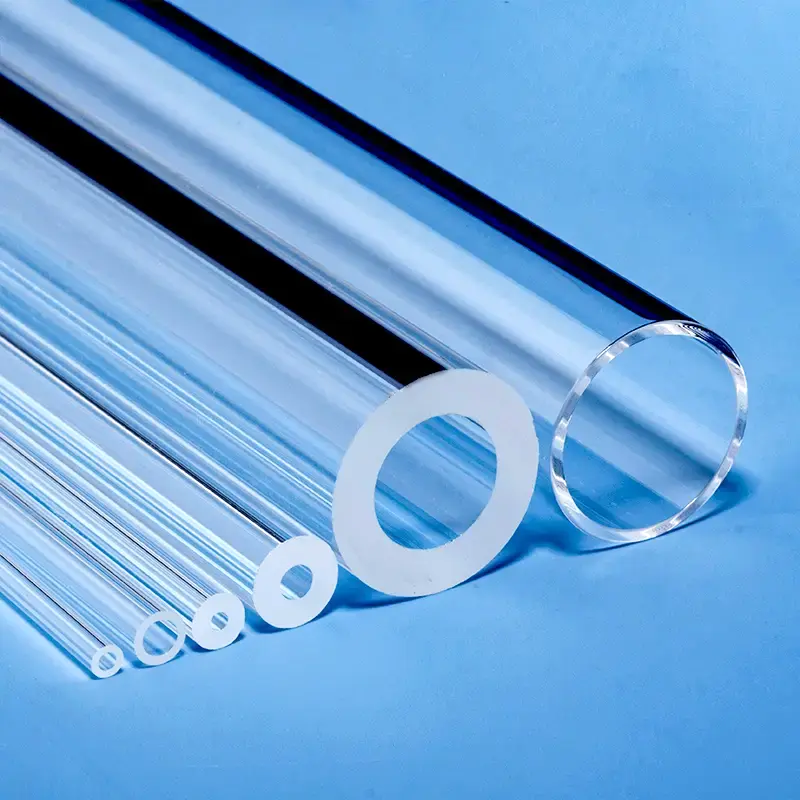

We specialize in the end-to-end manufacturing of high-purity quartz glass components. Our core product lines include:

Quartz Tubing & Rods: A wide range of diameters and specifications.

Quartz Plates & Discs: Precision-cut and polished for optical and industrial use.

Quartz Labware: A full suite of standard and custom glassware, including beakers, flasks, and boats.

Semiconductor-Grade Quartz: High-purity components like process tubes and carriers for semiconductor fabrication.

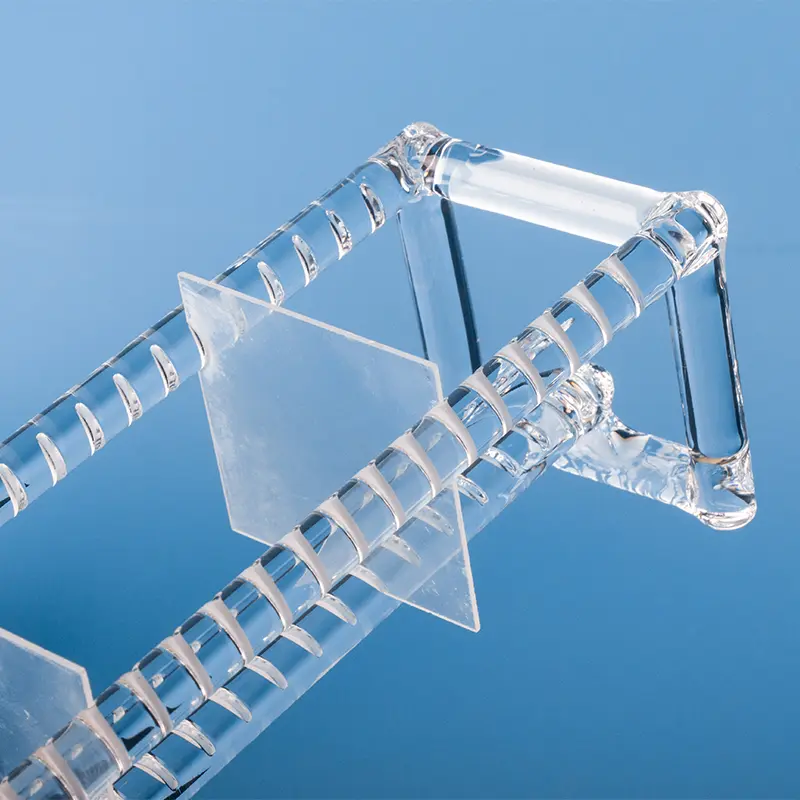

Custom Fabricated Components: We can produce complex parts tailored to your unique designs and specifications.

Yes. Custom fabrication is at the core of our business. With over a decade of specialized experience, we partner with companies to provide expert OEM/ODM services. Our capabilities include welding, grinding, drilling, polishing, bending, and other precision processing techniques to create components that meet your exact requirements.

Quality is paramount in our manufacturing process. We are an ISO 9001:2015 certified manufacturer, ensuring that our processes meet international quality management standards.Our products also undergo rigorous SGS testing for purity and performance. We use high-purity raw materials (up to 99.998% SiO2) to produce fused quartz and fused silica products with exceptional thermal stability, high-temperature resistance, and chemical inertness.

We've streamlined our process to be as efficient as possible:

Submit Your RFQ: Send us your technical drawings, specifications, and requirements via our website contact form or email.

Rapid Response: You can expect an initial response within minutes and detailed communication within half an hour.

Design & Proposal: We will deliver a detailed design proposal and a competitive quote within 24 hours.

Prototyping & Production: Upon approval, we move swiftly from prototyping to full-scale production to meet your deadlines.

Partnering with Aoxin Quartz offers several key advantages:

Proven Expertise: With 10+ years in the industry, we have the technical knowledge to tackle complex challenges.

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

Competitive Value: Located in a major quartz production hub, we leverage an efficient supply chain and advanced manufacturing to offer exceptional quality at a competitive price point.

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.