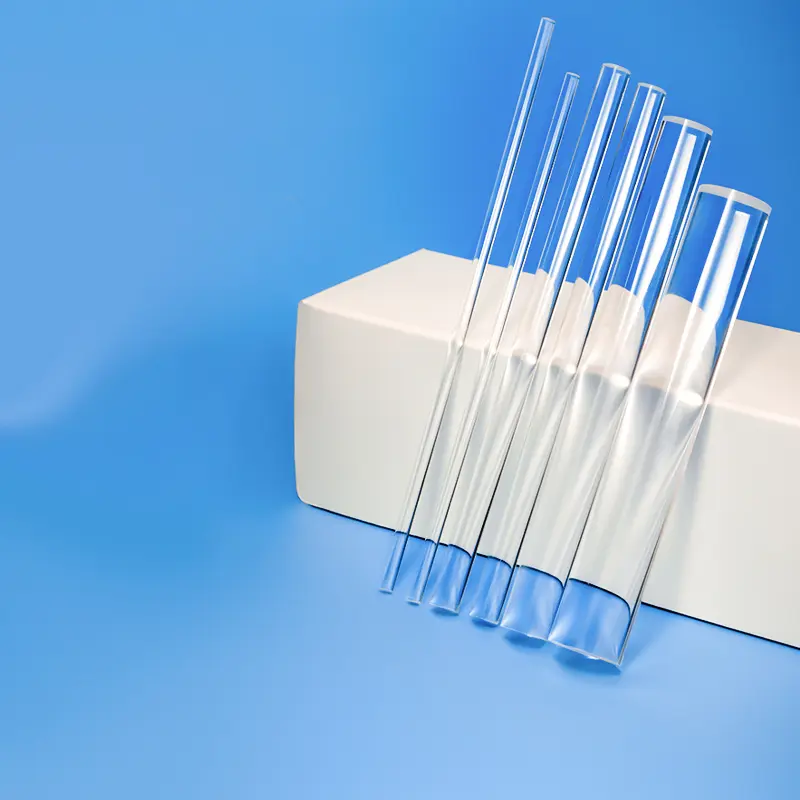

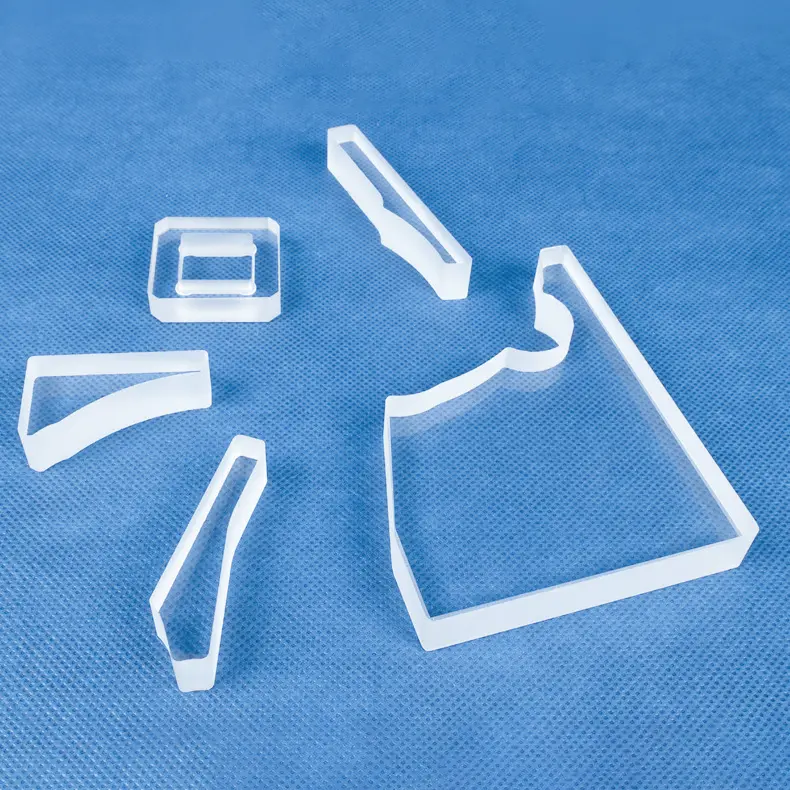

Our high-purity quartz V-grooved rods are precision-machined fused silica components for exact positioning in critical applications. Ideal for optical fiber alignment and semiconductor processes, these custom V-slotted rods offer exceptional high-temperature resistance and chemical inertness, ensuring reliable performance where precision is paramount.

| diameter | length |

|---|---|

| 10mm | 300mm |

| 10mm | 600mm |

| 12mm | 300mm |

| 12mm | 600mm |

| 14mm | 300mm |

| 14mm | 600mm |

| 15mm | 300mm |

| 15mm | 600mm |

| 15mm | 1000mm |

| 16mm | 300mm |

| 16mm | 600mm |

| 16mm | 1000mm |

| 16mm | 1200mm |

| 18mm | 300mm |

| 18mm | 600mm |

| 18mm | 1000mm |

| 18mm | 1200mm |

| 20mm | 300mm |

| 20mm | 600mm |

| 20mm | 1000mm |

| 20mm | 1200mm |

| 22mm | 300mm |

| 22mm | 600mm |

| 22mm | 1000mm |

| 22mm | 1200mm |

| 25mm | 300mm |

| 25mm | 600mm |

| 25mm | 1000mm |

| 25mm | 1200mm |

| 28mm | 300mm |

| 28mm | 600mm |

| 28mm | 1000mm |

| 28mm | 1200mm |

| 30mm | 300mm |

| 30mm | 600mm |

| 30mm | 1000mm |

| 30mm | 1200mm |

| 32mm | 300mm |

| 32mm | 600mm |

| 32mm | 1000mm |

| 32mm | 1200mm |

| 35mm | 300mm |

| 35mm | 600mm |

| 35mm | 1000mm |

| 35mm | 1200mm |

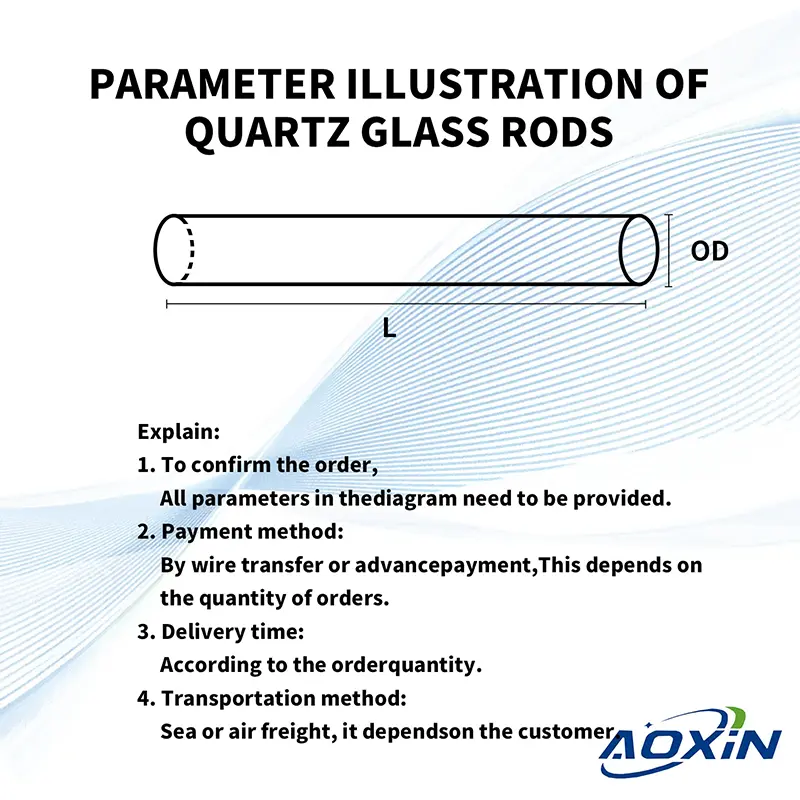

Remarks:

To confirm the order,

the following parameters are required:

① outer diameter ② length ③ quantity

- Payment method:

By T/T or prepayment,

It depends on the quantity of the order. - Delivery time:

According to the order quantity. - Shipping method:

By sea or by air,

It depends on the customer.

| Property Content | Property Values |

|---|---|

| SiO2 | 99.99% |

| Density | 2.2×10³ kg/cm³ |

| Hardness | 5.5 - 6.5 Mohs' Scale 570 KHN 100 |

| Tensile Strength | 4.8×10⁷ Pa (N/mm2) (7000 psi) |

| Compression Strength | >1.1×10⁹ Pa (160,000 psi) |

| Coefficient of Thermal Expansion | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| Thermal Conductivity | 1.4 W/m·°C |

| Specific Heat | 670 J/kg·°C |

| Softening Point | 1730°C (3146°F) |

| Annealing Point | 1210°C (2210°F) |

| Strain Point | 1120°C (2048°F) |

| Work Temperature | 1200°C (2192°F) |

| Electrical Resistivity | 7×10⁷ ohm cm (350°C) |

| Size | Customized |

| Logo | Customized Logo Accept |

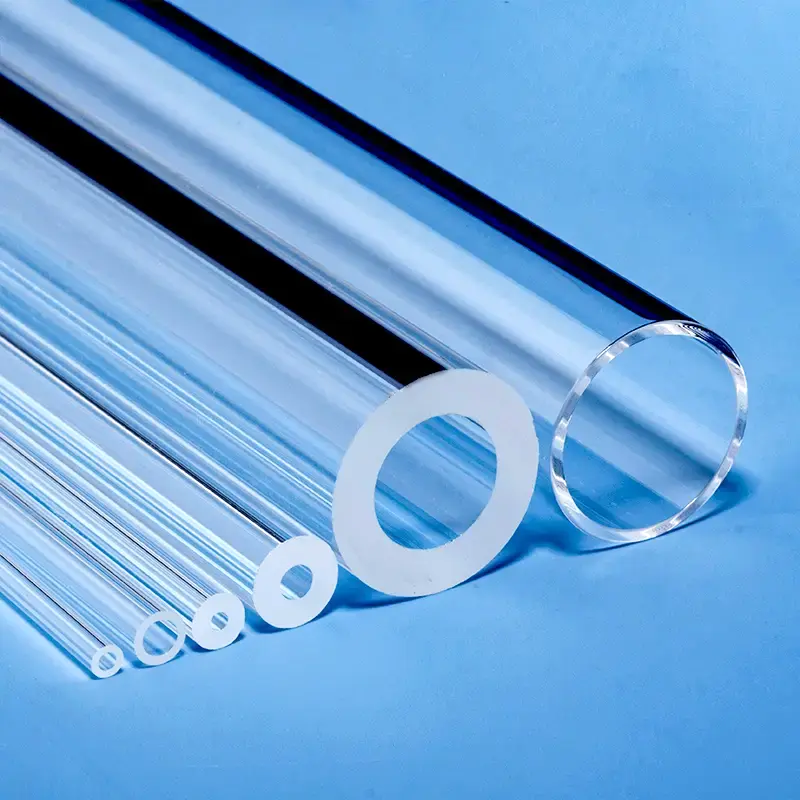

There are two primary methods for producing quartz rods: the continuous method and the flame fusion method (also known as the gas fusion method).

Continuous Method: In this method, quartz sand is fed from the top into a furnace, which comprises a metallic quartz crucible surrounded by electric heating elements. The quartz sand melts at high temperatures. The molten material then passes through a shaping orifice at the bottom of the crucible, producing rods, tubes, sheets, or other various specified product forms.

Flame Fusion Method: This method involves using hydrogen and oxygen to melt colorless quartz crystal. The molten material is formed into quartz glass through the melting and congealing of crystalline particles in the flame. The quartz glass is then removed from the flame through different methods and processed into quartz rods of the desired shape.

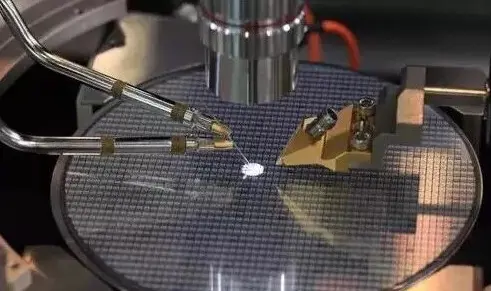

Semiconductor Industry

In the semiconductor manufacturing process, quartz slotted rods are used for machining critical components such as wafers. They ensure the precision and quality of the products through precise slotting processes.

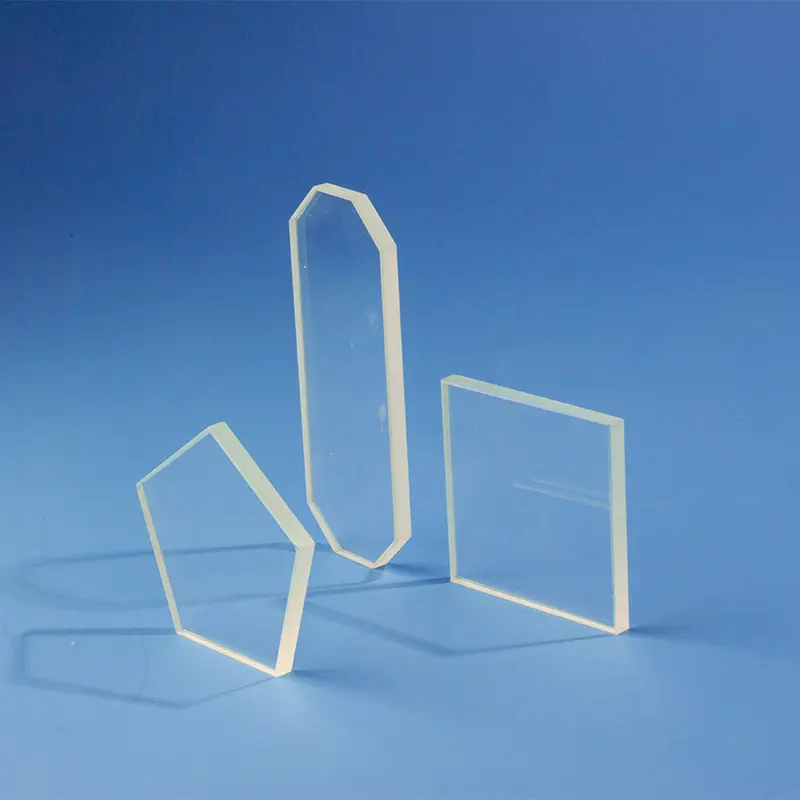

Optical Instrument Manufacturing

Quartz slotted rods are also widely used in the manufacturing of optical instruments, for applications like creating slots in lenses and prisms to meet the needs of high-precision optical systems.

Ceramics Industry

In the shaping and sintering of ceramics, quartz slotted rods are used for creating slots with specific shapes or structures, enhancing the quality and yield of ceramic products.

Other Industrial Applications

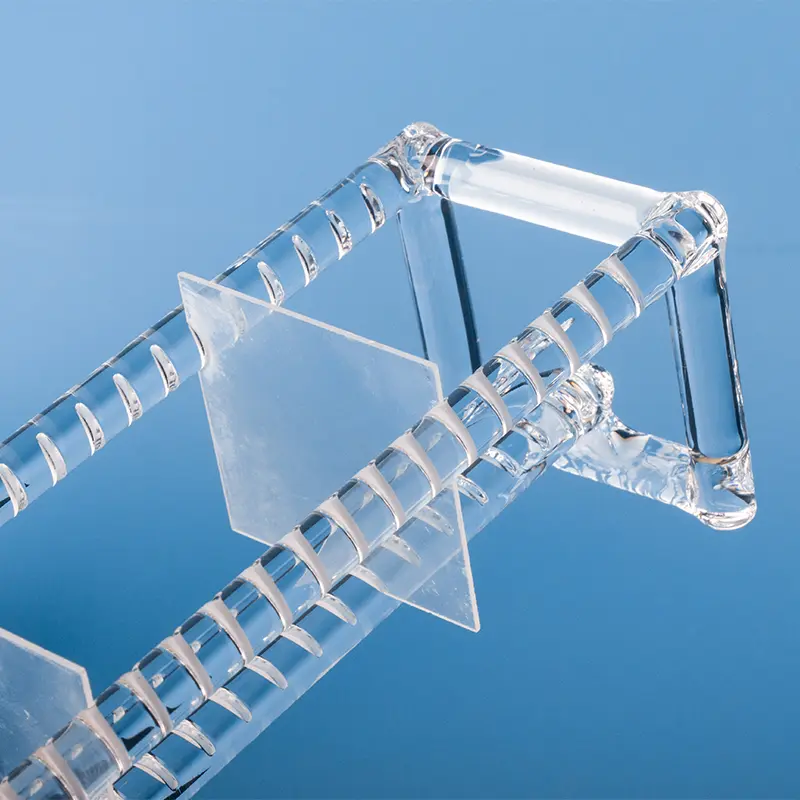

The structure of a quartz stirring rod generally includes the rod body, head, and connecting rod. Heads are designed in various shapes, such as disks or cones, to meet different stirring needs. Connecting rods are typically equipped with adjustment knobs for easy adjustment of the stirring rod length.

Application Scenario

The slotting process involves several steps: First, a quartz round rod is shaped into a square rod. Then, the ends of the square rod are cut, and the flatness, length, and perpendicularity of the square rod are inspected. Subsequently, the square rod is embedded into a graphite plate with an equal number of parallel “V”-shaped grooves on its upper surface. Liquid wax is then poured to secure the square rod to the “V”-shaped grooves. Finally, the liquid wax is cooled with water to solidify, completing the fixation of the square rod.

The slotting apparatus comprises a three-axis CNC machine tool with a graphite plate on its platform. The graphite plate features several parallel “V”-shaped grooves on its upper surface. This design helps improve the positioning and fixation of the quartz square rods, enhancing slotting precision.

Using quartz slotted rods offers multiple advantages, including improving the efficiency of slotting multiple square rods simultaneously, ensuring post-slotting precision, reducing damage to square rods during the slotting process, and facilitating easy removal of the slotted square rods.

Frequently asked questions

We specialize in the end-to-end manufacturing of high-purity quartz glass components. Our core product lines include:

Quartz Tubing & Rods: A wide range of diameters and specifications.

Quartz Plates & Discs: Precision-cut and polished for optical and industrial use.

Quartz Labware: A full suite of standard and custom glassware, including beakers, flasks, and boats.

Semiconductor-Grade Quartz: High-purity components like process tubes and carriers for semiconductor fabrication.

Custom Fabricated Components: We can produce complex parts tailored to your unique designs and specifications.

Yes. Custom fabrication is at the core of our business. With over a decade of specialized experience, we partner with companies to provide expert OEM/ODM services. Our capabilities include welding, grinding, drilling, polishing, bending, and other precision processing techniques to create components that meet your exact requirements.

Quality is paramount in our manufacturing process. We are an ISO 9001:2015 certified manufacturer, ensuring that our processes meet international quality management standards.Our products also undergo rigorous SGS testing for purity and performance. We use high-purity raw materials (up to 99.998% SiO2) to produce fused quartz and fused silica products with exceptional thermal stability, high-temperature resistance, and chemical inertness.

We've streamlined our process to be as efficient as possible:

Submit Your RFQ: Send us your technical drawings, specifications, and requirements via our website contact form or email.

Rapid Response: You can expect an initial response within minutes and detailed communication within half an hour.

Design & Proposal: We will deliver a detailed design proposal and a competitive quote within 24 hours.

Prototyping & Production: Upon approval, we move swiftly from prototyping to full-scale production to meet your deadlines.

Partnering with Aoxin Quartz offers several key advantages:

Proven Expertise: With 10+ years in the industry, we have the technical knowledge to tackle complex challenges.

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

Competitive Value: Located in a major quartz production hub, we leverage an efficient supply chain and advanced manufacturing to offer exceptional quality at a competitive price point.

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.