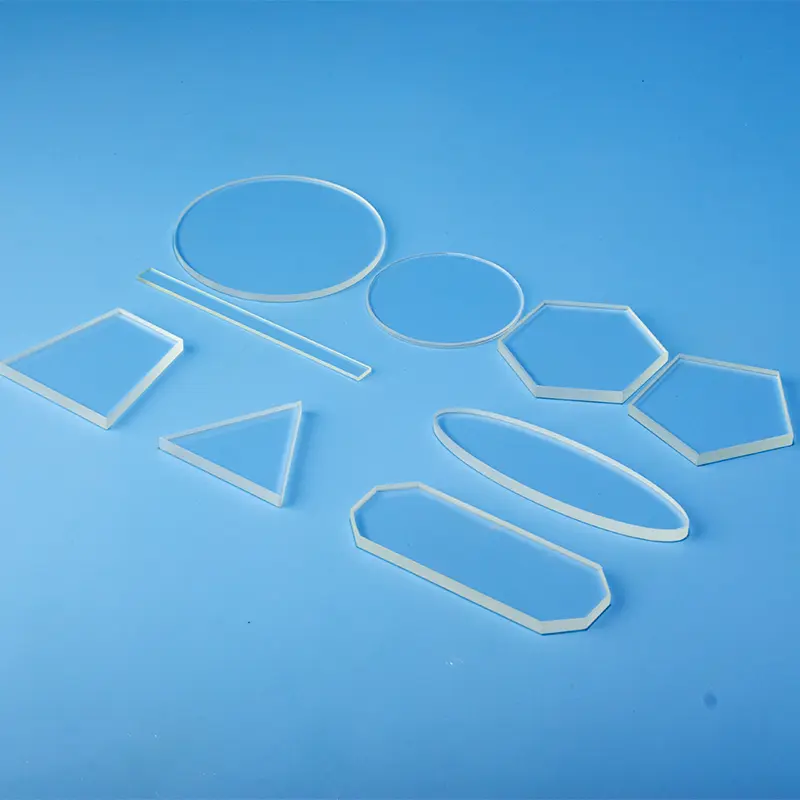

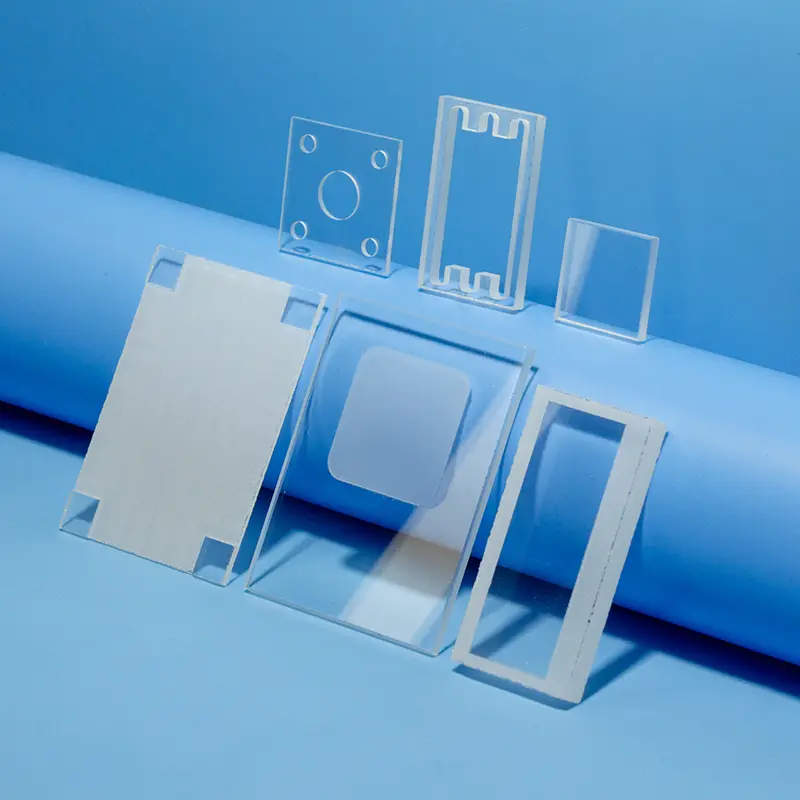

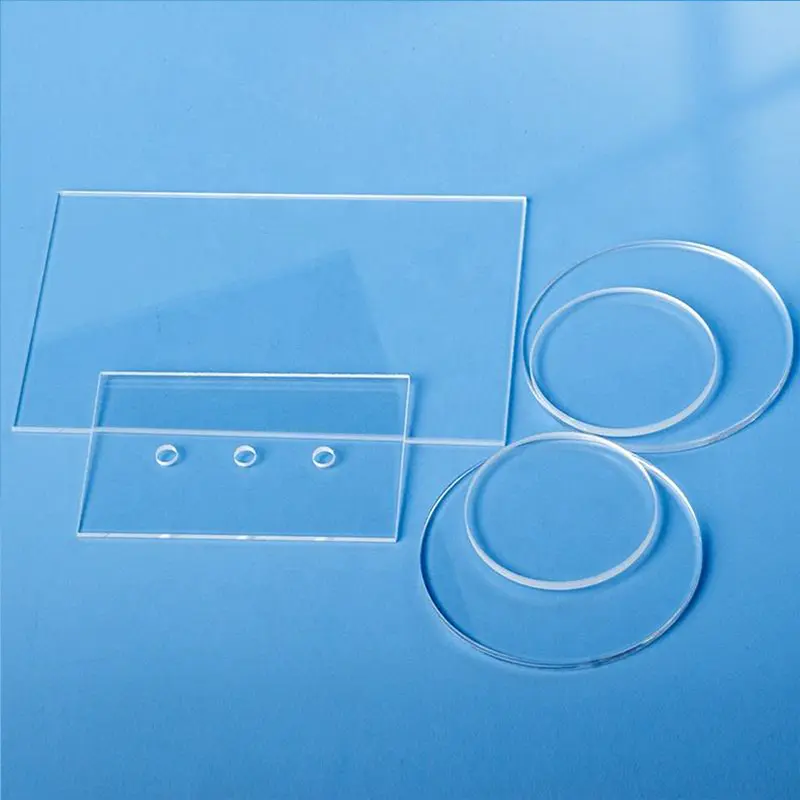

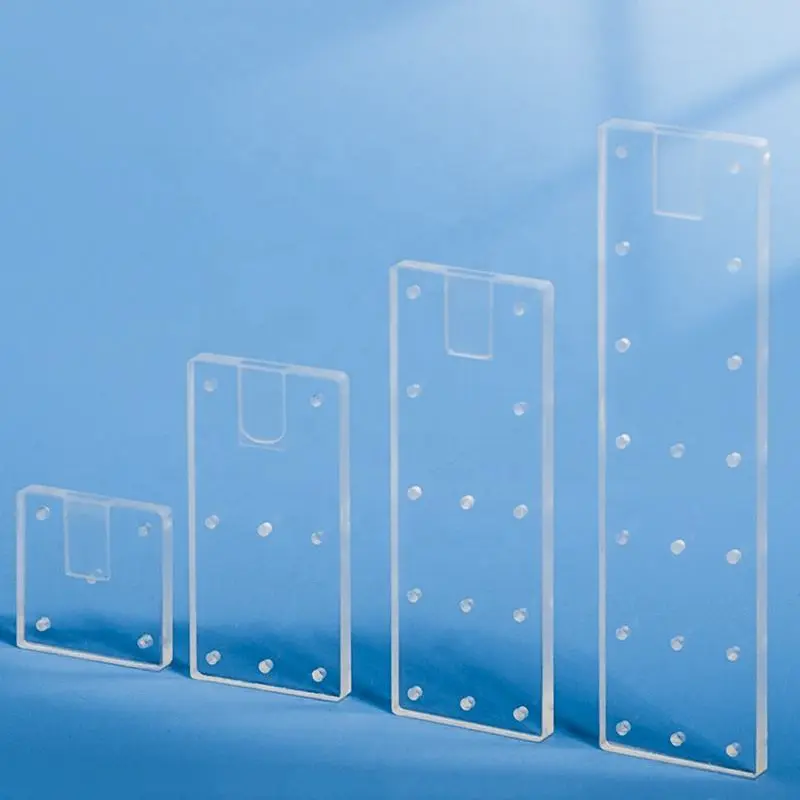

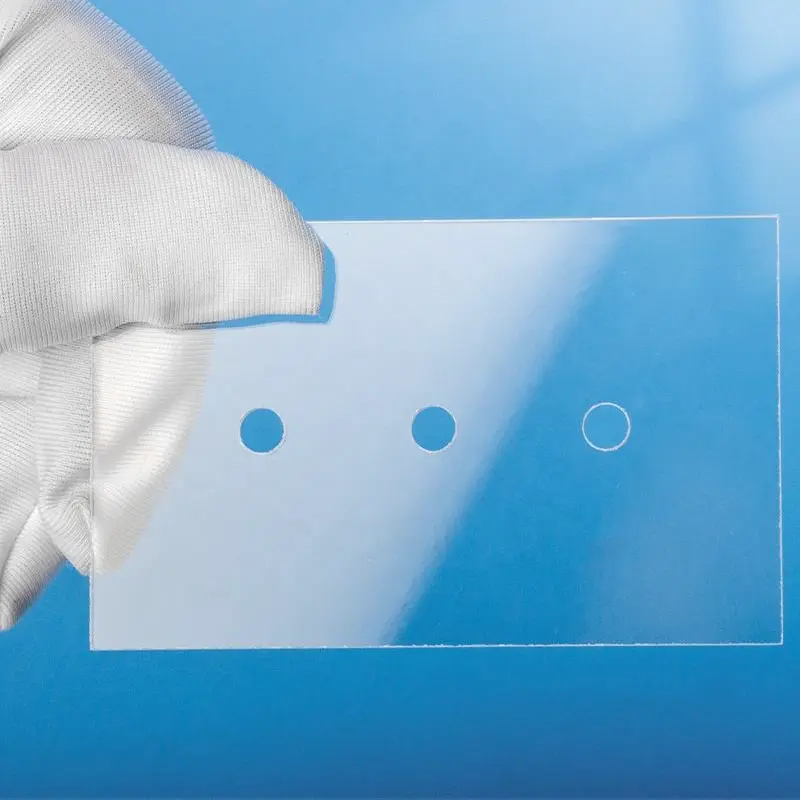

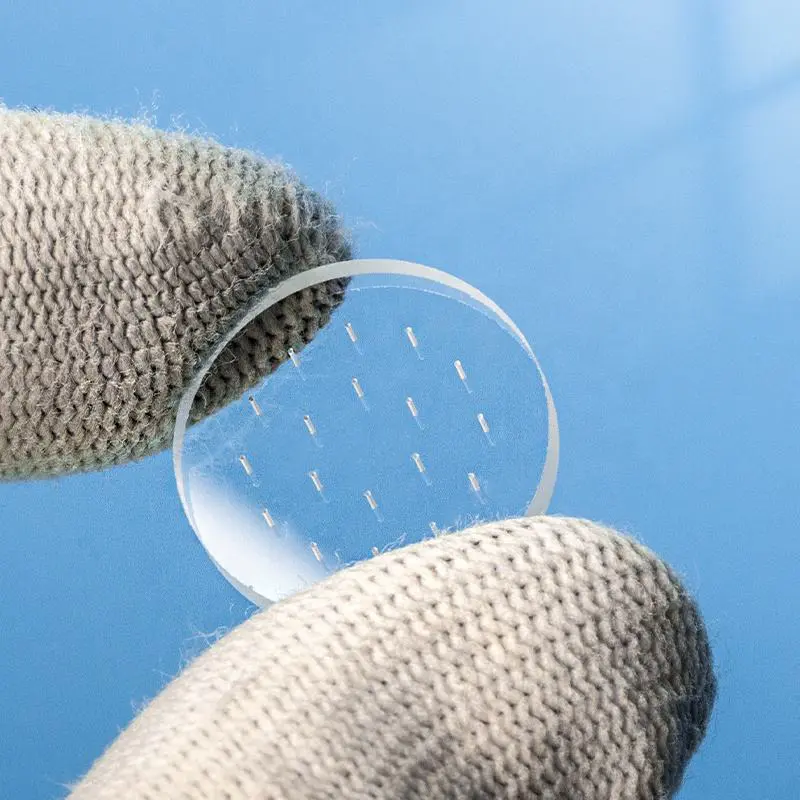

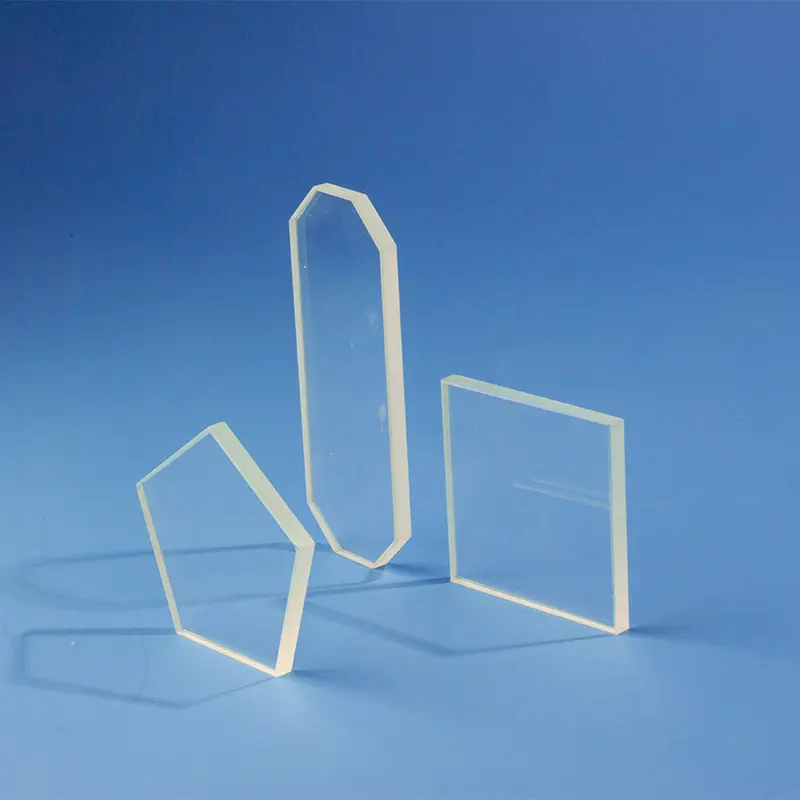

Unsere Quarzglasplatten sind präzisionsgefertigte Komponenten aus hochreinem Quarzglas (geschmolzenes Siliziumdioxid), die eine außergewöhnliche Transparenz und optische Klarheit bieten. Diese robusten Platten zeichnen sich durch eine überragende Beständigkeit gegenüber hohen Temperaturen und aggressiven Chemikalien sowie einen sehr niedrigen Wärmeausdehnungskoeffizienten aus. Mit exzellenten elektrischen Isolationseigenschaften sind unsere Quarzplatten unverzichtbar für anspruchsvolle Anwendungen in der Glasfaserkommunikation, der Halbleiterfertigung und in medizinischen Geräten. Sie sind in einer breiten Palette von Standardabmessungen und Dicken erhältlich, um Ihren spezifischen technischen Anforderungen gerecht zu werden

| Länge | Breite | Dicke |

|---|---|---|

| 5 mm | 5 mm | 1mm |

| 10mm | 10mm | 0,5 mm |

| 10mm | 10mm | 1mm |

| 10mm | 10mm | 2mm |

| 12mm | 12mm | 1mm |

| 15mm | 15mm | 0,5 mm |

| 15mm | 15mm | 1mm |

| 15mm | 15mm | 2mm |

| 15mm | 15mm | 3mm |

| 20mm | 20mm | 0,5 mm |

| 20mm | 20mm | 1mm |

| 20mm | 20mm | 2mm |

| 20mm | 20mm | 3mm |

| 25mm | 25mm | 0,5 mm |

| 25mm | 25mm | 1mm |

| 25mm | 25mm | 2mm |

| 25mm | 25mm | 3mm |

| 30mm | 30mm | 0,5 mm |

| 30mm | 30mm | 1mm |

| 30mm | 30mm | 2mm |

| 30mm | 30mm | 3mm |

| 35mm | 35mm | 1mm |

| 35mm | 35mm | 2mm |

| 35mm | 35mm | 3mm |

| 40mm | 40mm | 0,5 mm |

| 40mm | 40mm | 1mm |

| 40mm | 40mm | 2mm |

| 40mm | 40mm | 3mm |

| 45 mm | 45 mm | 1mm |

| 45 mm | 12mm | 1mm |

| 45 mm | 12mm | 2mm |

| 35mm | 35mm | 2mm |

| 50mm | 50mm | 0,5 mm |

| 50mm | 50mm | 1mm |

| 50mm | 50mm | 2mm |

| 50mm | 50mm | 3mm |

| 50mm | 50mm | 4mm |

| 50mm | 50mm | 5 mm |

| 60mm | 60mm | 1mm |

| 60mm | 60mm | 2mm |

| 60mm | 60mm | 3mm |

| 70mm | 70mm | 2mm |

| 70mm | 70mm | 3mm |

| 70mm | 70mm | 5 mm |

| 75mm | 25mm | 0,5 mm |

| 75mm | 25mm | 1mm |

| 75mm | 25mm | 2mm |

| 80mm | 80mm | 1mm |

| 80mm | 80mm | 2mm |

| 80mm | 80mm | 3mm |

| 80mm | 80mm | 4mm |

| 100mm | 100mm | 1mm |

| 100mm | 100mm | 1,5 mm |

| 100mm | 100mm | 2mm |

| 100mm | 100mm | 3mm |

| 100mm | 100mm | 5 mm |

| 100mm | 100mm | 0,5 mm |

| 100mm | 100mm | 1mm |

| 100mm | 100mm | 2mm |

| 100mm | 100mm | 3mm |

| 100mm | 100mm | 5 mm |

| 150mm | 150mm | 2mm |

| 150mm | 150mm | 3mm |

| 150mm | 150mm | 5 mm |

- Zahlungsmethode: Per Banküberweisung oder Vorkasse, abhängig von der Bestellmenge.

- Lieferzeit: Abhängig von der Bestellmenge

- Transportmethode: Seefracht oder Luftfracht, abhängig vom Kunden

Anmerkungen:

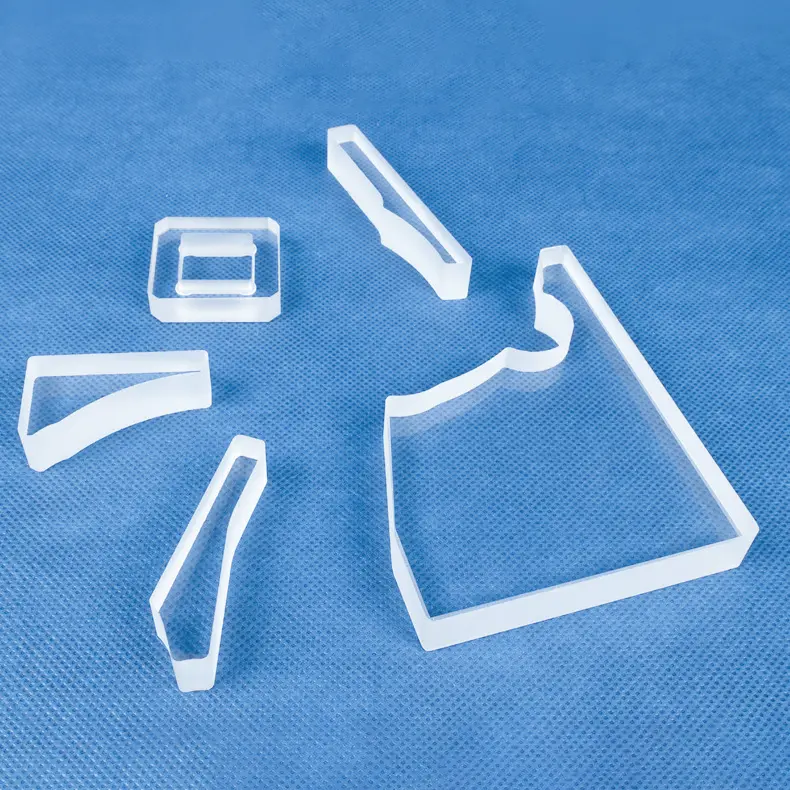

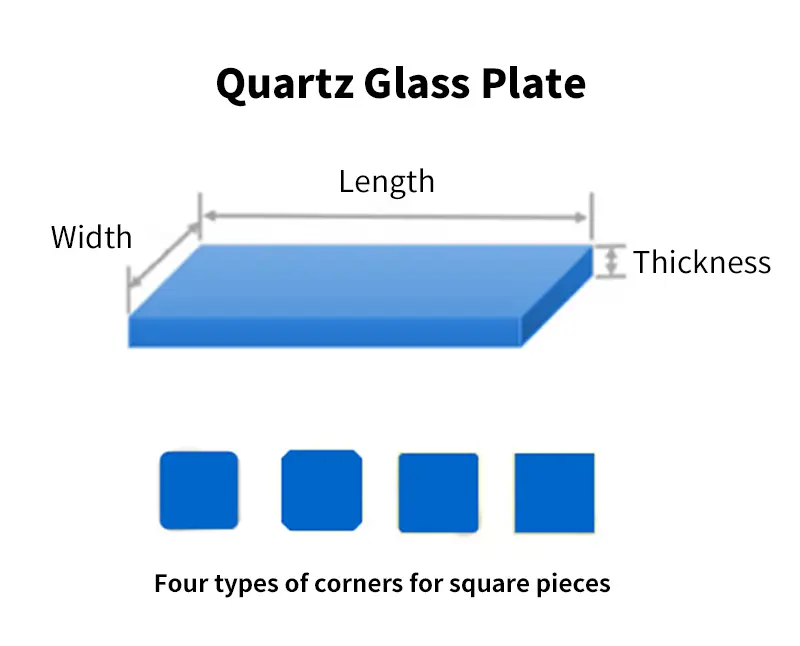

Um die Bestellung zu bestätigen, müssen die folgenden Parameter bereitgestellt werden: ① Quadrat: Länge, Breite, Dicke ② Kreis: Durchmesser, Dicke ③ Genauigkeit ④ Menge

| Eigenschaftsinhalt | Eigenschaftswerte |

|---|---|

| SiO2 | 99.99% |

| Dichte | 2,2×10³ kg/cm³ |

| Härte | Mohs-Härte 5,5 - 6,5; Knoop-Härte 570 (bei 100 g Prüflast) |

| Zugfestigkeit | 4,8 × 10⁷ Pa (48 N/mm² bzw. 48 MPa); 7.000 psi |

| Druckfestigkeit | >1.1×10⁹ Pa (160,000 psi) |

| Wärmeausdehnungskoeffizient | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| Wärmeleitfähigkeit | 1,4 W/m-°C |

| Spezifische Wärme | 670 J/kg-°C |

| Erweichungspunkt | 1730°C (3146°F) |

| Transformationspunkt | 1210°C (2210°F) |

| Spannungspunkt | 1120°C (2048°F) |

| Arbeitstemperatur | 1200°C (2192°F) |

| Elektrischer Widerstand | 7×10⁷ Ohm cm (350°C) |

| Größe | Kundenspezifisch |

| Logo | Personalisierung mit Logo |

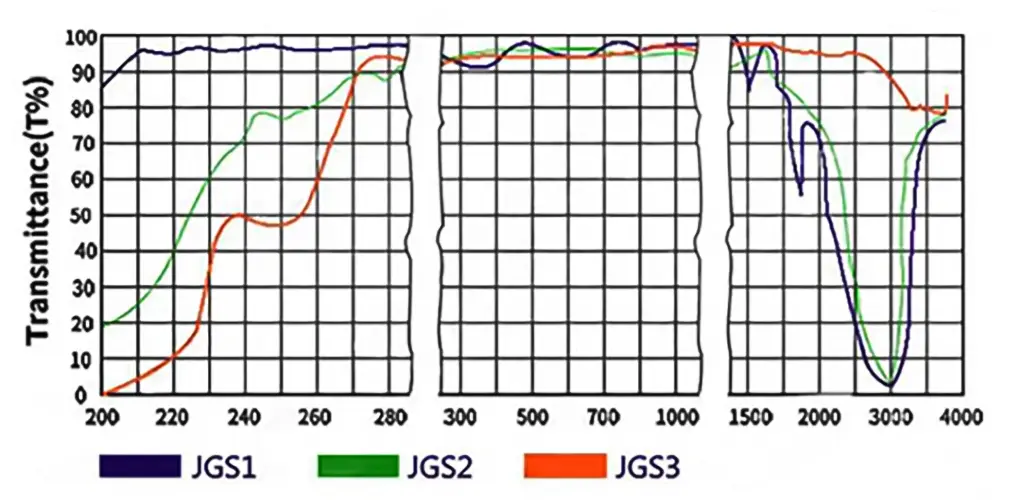

JGS1

Dieses Material, allgemein bekannt als UV-Quarzglas, weist eine außergewöhnlich geringe Dispersion und eine sehr hohe Transmission im ultravioletten (UV) Spektralbereich auf

JGS2

Ähnlich wie JGS1, können jedoch je nach Herstellerstandard Abweichungen bei spezifischen Leistungsparametern wie Transmission und Wärmeausdehnungskoeffizient auftreten

JGS3

Typischerweise wird dieses Material in Anwendungen eingesetzt, die eine höhere Reinheit oder spezialisierte Leistungseigenschaften erfordern. Spezifische Leistungsparameter können je nach Hersteller variieren

Dispersionseigenschaften

JGS1- und JGS2-Quarzplatten weisen im ultravioletten (UV) Spektralbereich exzellente Dispersionseigenschaften auf, wodurch UV-Licht unterschiedlicher Wellenlängen effektiv getrennt wird. Dies macht sie ideal für die Herstellung hochleistungsfähiger optischer Komponenten.

Transmissionsgrad

Alle drei Arten von Quarzplatten weisen eine hohe Transmission für UV-Licht auf, insbesondere innerhalb spezifischer Wellenlängenbereiche. Zum Beispiel besitzt JGS1 eine sehr hohe Transmission von 185 nm bis 2.500 nm. Dies macht sie zu den bevorzugten Materialien für die Herstellung von UV-Lasern, UV-Spektrometern und optischen Filtern.

Chemische Stabilität

Quarzplatten weisen eine hervorragende chemische Stabilität auf und können extremen Bedingungen standhalten, einschließlich Säuren, Laugen und hohen Temperaturen. Daher sind sie geeignet für die Herstellung von Chemiereaktoren, Hochtemperatur-Ofenfenstern und chemischen Analysegeräten.

Niedriger thermischer Ausdehnungskoeffizient

Diese Quarzblätter weisen sehr niedrige Wärmeausdehnungskoeffizienten auf und zeigen eine minimale Reaktion auf Temperaturänderungen. Dies ist entscheidend für die Stabilität von hochpräzisen optischen Komponenten.

Anwendungsszenario

Quarzplatten weisen hervorragende Hochtemperatureigenschaften, Korrosionsbeständigkeit, thermische Stabilität und Lichtdurchlässigkeit auf. Der Erstarrungspunkt liegt bei etwa 1730 °C, und sie können kontinuierlich bei 1100 °C verwendet werden, wobei eine kurzfristige Anwendung bis 1450 °C möglich ist. Quarzglas ist gegenüber Säuren, mit Ausnahme von Flusssäure, sehr beständig und zeigt eine hohe Widerstandsfähigkeit gegenüber chemischen Reaktionen mit den meisten anderen Säuren. Quarzplatten haben einen sehr niedrigen thermischen Ausdehnungskoeffizienten, der es ihnen ermöglicht, plötzliche Temperaturänderungen ohne Bruch zu überstehen. Sie zeigen auch eine gute Lichtdurchlässigkeit über das gesamte UV- bis IR-Spektrum, mit einer Lichtdurchlässigkeit im sichtbaren Bereich von über 93 %.

Basierend auf den optischen Eigenschaften werden Quarzplatten in drei Kategorien unterteilt: Fernultraviolett (FUV) optisches Quarzglas (JGS1), ultraviolettes (UV) optisches Quarzglas (JGS2) und infrarotes (IR) optisches Quarzglas (JGS3). Diese verschiedenen Arten von Quarzglas weisen Variationen in der Transparenz, den Absorptionsbandpositionen usw. im UV- und sichtbaren Spektralbereich auf.

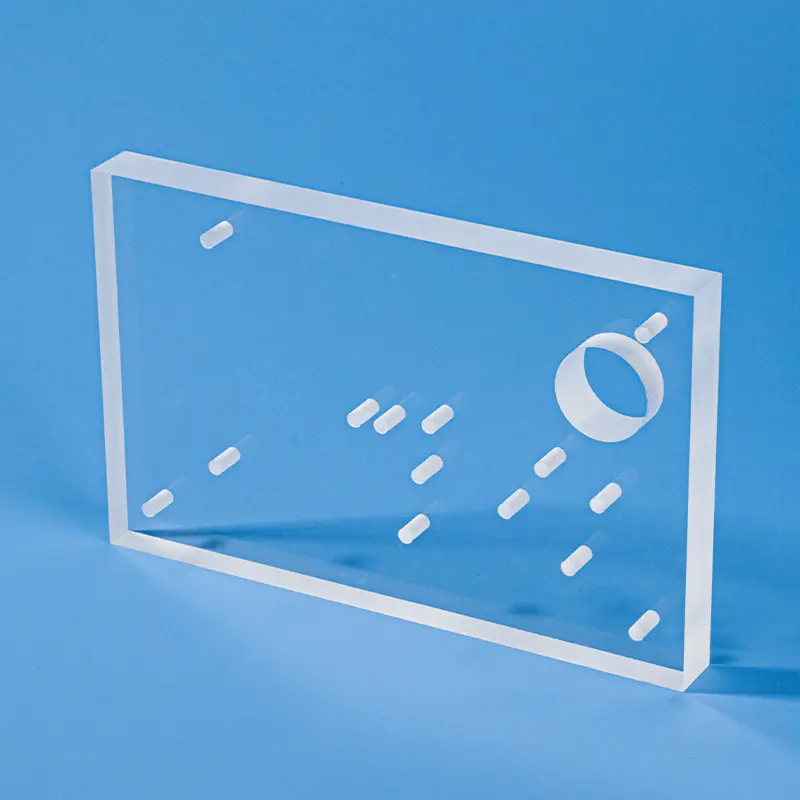

Die Bearbeitung von Quarzplatten umfasst grobe Verarbeitungsschritte wie das Sortieren von Rohmaterialien, das Verkleben von Stäben, das Schneiden von Keimkristallen und das Abrunden. Darauf folgen Schleifphasen wie das Grobschleifen, Mittelschleifen und Feinschleifen. Anschließend werden Polier- und Reinigungsvorgänge durchgeführt, um die Oberflächenqualität und Stabilität der Wafer zu gewährleisten. Schließlich erfolgt die Montage und das Die-Bonding, bei dem die Quarzplatten mit aufgebrachten Elektroden fixiert und leitfähiger Kleber auf die Kontaktpunkte zwischen den Elektroden und den Metallpads aufgetragen wird, um eine elektrische Verbindung herzustellen.

Häufig gestellte Fragen

Wir sind auf die durchgängige Fertigung von hochreinen Quarzglaskomponenten spezialisiert. Unsere Kernproduktlinien umfassen:

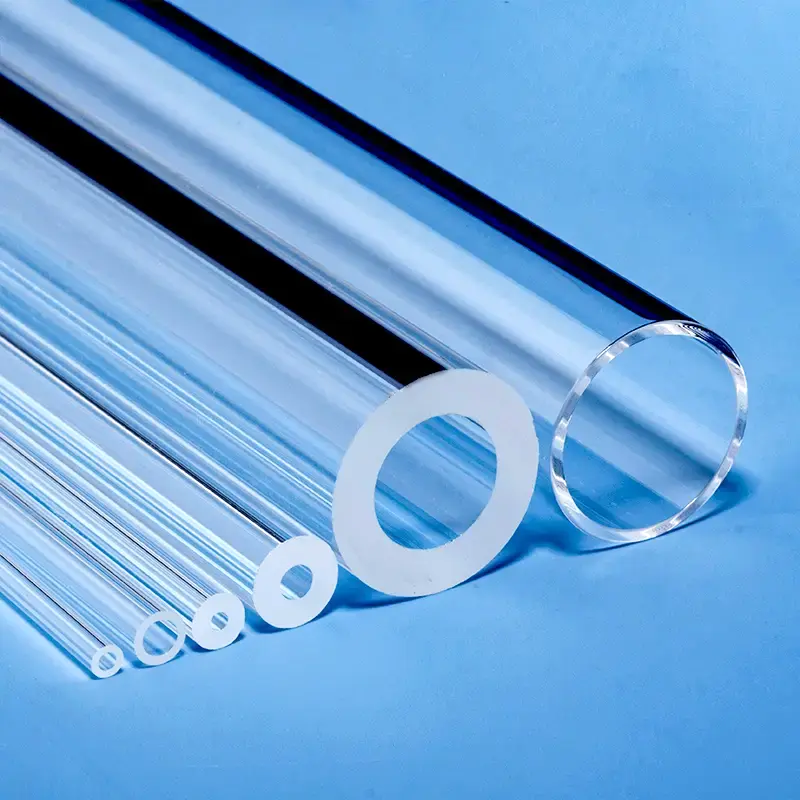

Quarzrohre & -stäbe: Eine große Auswahl an Durchmessern und Spezifikationen.

Quarzplatten & -scheiben: Präzisionsgeschnitten und poliert für optische und industrielle Anwendungen.

Quarzlaborglas: Ein komplettes Sortiment an Standard- und kundenspezifischen Glasgeräten, einschließlich Bechergläsern, Kolben und Booten.

Halbleiterquarz: Hochreine Komponenten wie Prozessrohre und Träger für die Halbleiterfertigung.

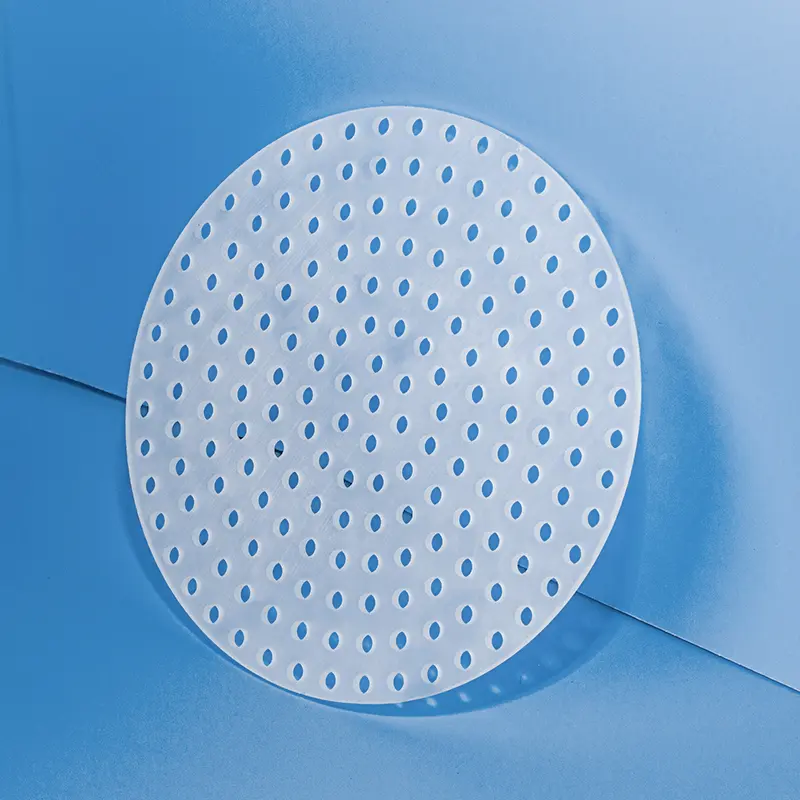

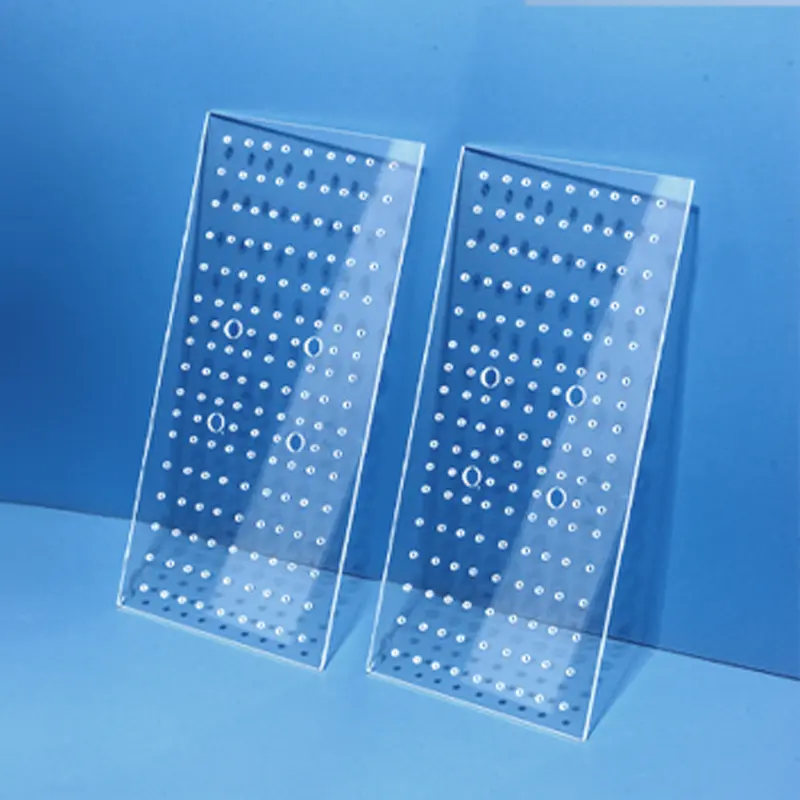

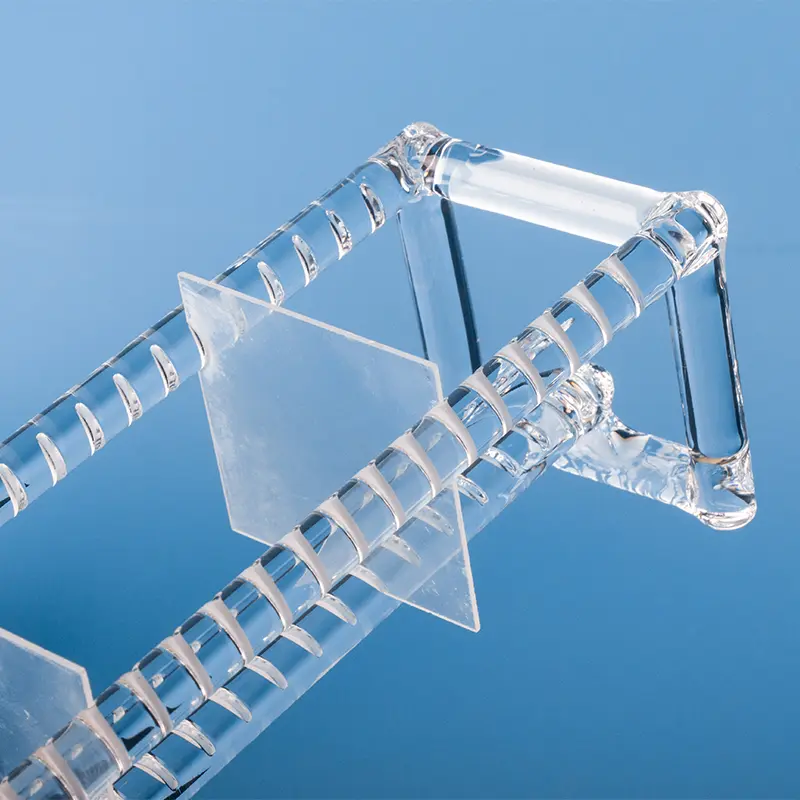

Kundenspezifische Fertigungskomponenten: Wir können komplexe Teile nach Ihren einzigartigen Designs und Spezifikationen fertigen.

Ja. Kundenspezifische Fertigung ist das Herzstück unseres Geschäfts. Mit über einem Jahrzehnt spezialisierter Erfahrung arbeiten wir eng mit Unternehmen zusammen, um erstklassige OEM/ODM-Dienstleistungen anzubieten. Unsere Kompetenzen umfassen Schweißen, Schleifen, Bohren, Polieren, Biegen und weitere Präzisionsbearbeitungstechniken, um Komponenten zu fertigen, die exakt Ihren Anforderungen entsprechen.

Qualität ist in unserem Herstellungsprozess von größter Bedeutung. Wir sind ein ISO 9001:2015 zertifizierter Hersteller, der sicherstellt, dass unsere Prozesse internationale Qualitätsmanagementstandards erfüllen.Unsere Produkte durchlaufen zudem rigorose SGS-Prüfungen hinsichtlich Reinheit und Leistung. Wir verwenden hochreine Rohmaterialien (bis zu 99,998% SiO2), um Quarzglas- und Kieselglasprodukte mit außergewöhnlicher thermischer Stabilität, hoher Temperaturbeständigkeit und chemischer Inertheit herzustellen.

Wir haben unsere Prozesse maximal effizient gestaltet:

Senden Sie Ihre Angebotsanfrage (RFQ): Senden Sie uns Ihre technischen Zeichnungen, Spezifikationen und Anforderungen über unser Kontaktformular auf der Website oder per E-Mail.

Schnelle Reaktion: Sie können eine erste Antwort innerhalb weniger Minuten und eine detaillierte Kommunikation innerhalb einer halben Stunde erwarten.

Design & Angebot: Wir liefern Ihnen innerhalb von 24 Stunden einen detaillierten Designvorschlag und ein wettbewerbsfähiges Angebot.

Prototypenentwicklung & Produktion: Nach Freigabe gehen wir zügig von der Prototypenfertigung zur Serienproduktion über, um Ihre Fristen einzuhalten.

Eine Partnerschaft mit Aoxin Quartz bietet mehrere entscheidende Vorteile:

Nachgewiesene Expertise: Mit über 10 Jahren Branchenerfahrung verfügen wir über das technische Fachwissen, um komplexe Herausforderungen zu meistern.

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

Wettbewerbsfähiger Wert: Als Standort in einem wichtigen Quarzproduktionszentrum nutzen wir eine effiziente Lieferkette und fortschrittliche Fertigung, um außergewöhnliche Qualität zu einem wettbewerbsfähigen Preis anzubieten.

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.