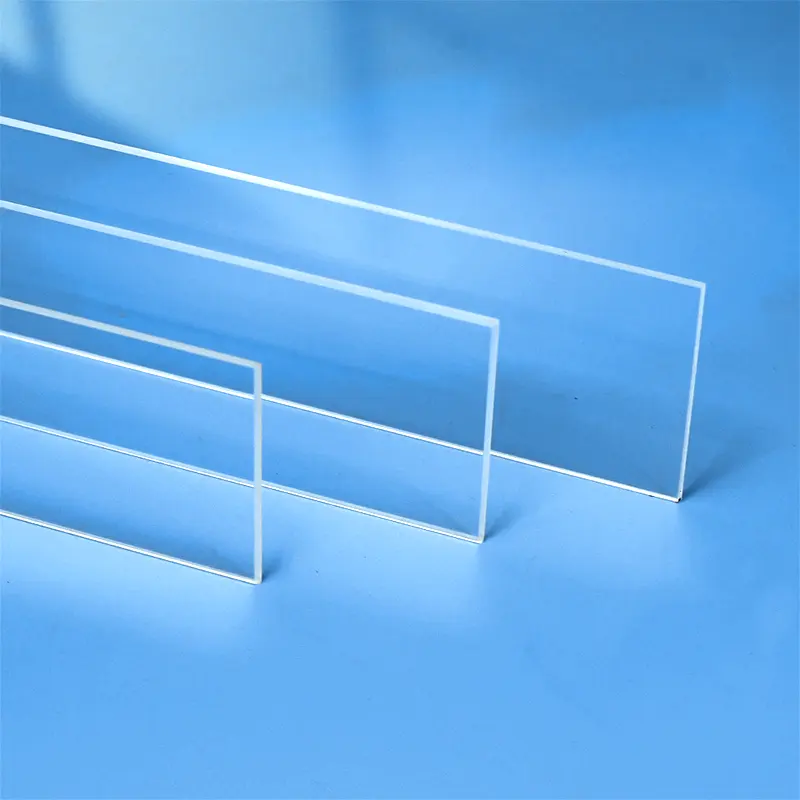

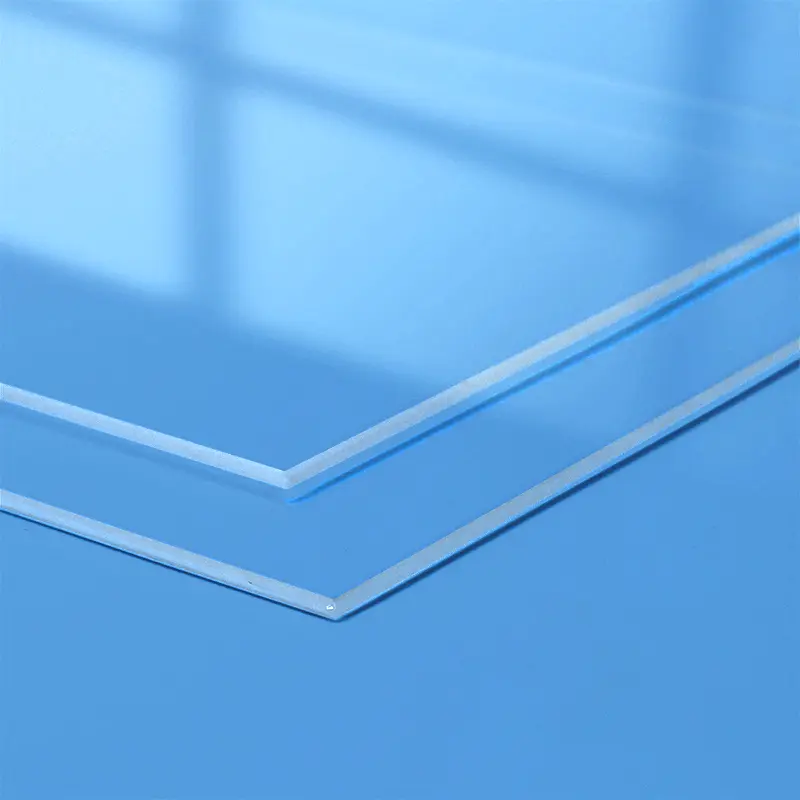

Unsere optischen Quarzglasplatten werden präzise aus hochreinem Quarzglas gefertigt, ideal für optische, Halbleiter- und Laseranwendungen. Wir bieten kundenspezifische Quarzglasfenster und -platten, die sich durch hervorragende UV-Transmission, thermische Stabilität und chemische Beständigkeit auszeichnen

| Eigenschaftsinhalt | Eigenschaftswerte |

|---|---|

| SiO2 | 99.99% |

| Dichte | 2,2×10³ kg/cm³ |

| Härte | Mohs-Härte 5,5 - 6,5; Knoop-Härte 570 (bei 100 g Prüflast) |

| Zugfestigkeit | 4,8 × 10⁷ Pa (48 N/mm² bzw. 48 MPa); 7.000 psi |

| Druckfestigkeit | >1.1×10⁹ Pa (160,000 psi) |

| Wärmeausdehnungskoeffizient | 5.5×10⁻⁷ cm/cm·°C (20°C-320°C) |

| Wärmeleitfähigkeit | 1,4 W/m-°C |

| Spezifische Wärme | 670 J/kg-°C |

| Erweichungspunkt | 1730°C (3146°F) |

| Transformationspunkt | 1210°C (2210°F) |

| Spannungspunkt | 1120°C (2048°F) |

| Arbeitstemperatur | 1200°C (2192°F) |

| Elektrischer Widerstand | 7×10⁷ Ohm cm (350°C) |

| Größe | Kundenspezifisch |

| Logo | Personalisierung mit Logo |

Hohe Transparenz

Quarzglasplatten weisen eine extrem hohe Transparenz auf, insbesondere im ultravioletten bis infraroten Spektralbereich. Dies macht sie in optischen Anwendungen, wie der Herstellung von Linsen, Glasfasern und optischen Fenstern, von unschätzbarem Wert.

Hohe Temperaturbeständigkeit

Quarzglasplatten halten außergewöhnlich hohen Temperaturen stand, mit Dauereinsatztemperaturen von bis zu 1100°C und einer Kurzzeittoleranz von bis zu 1250°C. Dies macht sie ideal für Hochtemperaturumgebungen, wie sie in der Halbleiterfertigung und als Schaugläser in Hochtemperaturöfen vorkommen

Chemische Stabilität

Quarzglasplatten weisen eine ausgezeichnete Beständigkeit gegenüber den meisten Chemikalien, insbesondere Säuren, auf. Mit Ausnahme von Flusssäure zeigen sie gegenüber nahezu allen Säuren eine nahezu Inertheit, was sie in chemischen Laboren und industriellen Anwendungen sehr begehrt macht

Niedriger thermischer Ausdehnungskoeffizient

Quarzglasplatten besitzen einen niedrigen Wärmeausdehnungskoeffizienten, wodurch sich ihre Abmessungen bei Temperaturschwankungen nur sehr geringfügig ändern. Dies ist entscheidend für Präzisionsinstrumente und Hochtemperaturgeräte, die eine präzise Dimensionskontrolle erfordern, und gewährleistet Stabilität und Zuverlässigkeit unter wechselnden Temperaturen.

Anwendungsszenario

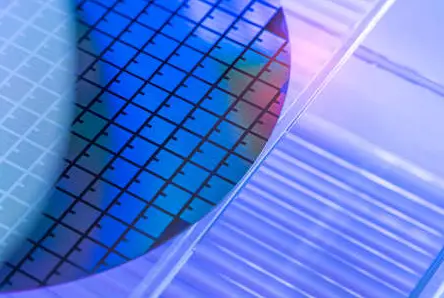

Halbleiterindustrie

Quarzglasplatten spielen eine entscheidende Rolle in der Halbleiterlieferkette und werden in der Produktion von Einkristall-Silizium und bei Wafer-Fertigungsprozessen breit eingesetzt. Verschiedene Quarzkomponenten und -instrumente sind in den Schritten Reinigung, Oxidation, Photolithographie, Ätzen und Diffusion unerlässlich. Beispielsweise sind Quarztiegel unverzichtbare Behälter in der Halbleiterindustrie, während hochreine Quarzprodukte wie Quarzglasplatten, Quarzringe und Quarzboote ebenfalls in diesen Prozessen verwendet werden

Glasfaserkommunikationsindustrie

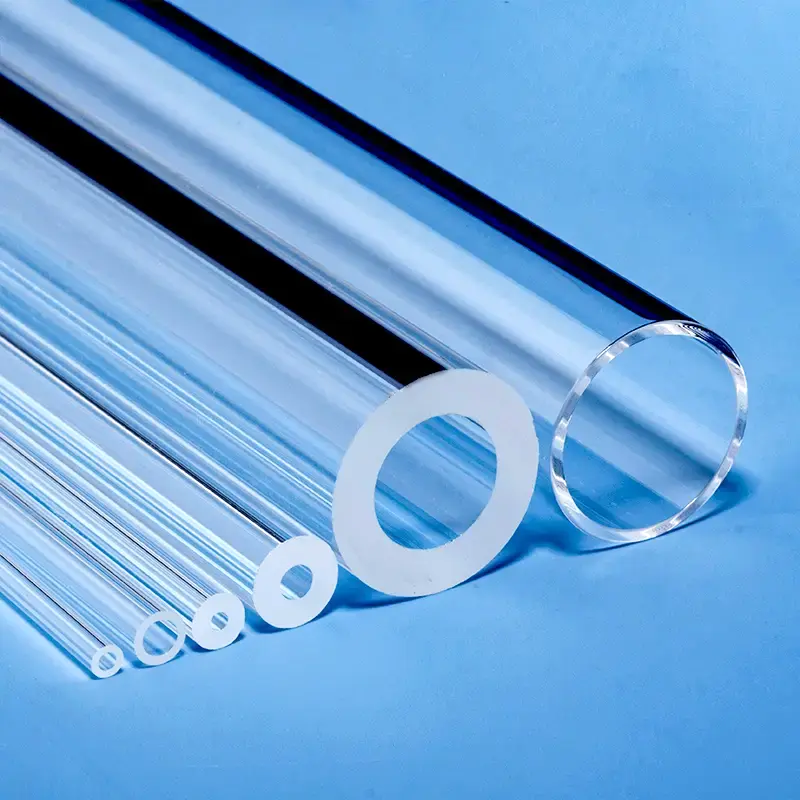

Quarzglas ist der primäre Rohstoff in der Glasfaserherstellung, wobei hochreines Quarzglas mehr als 95% der Zusammensetzung von Glasfaser-Preforms ausmacht. Erhebliche Mengen an Quarzglasmaterialien, wie Haltestäbe und Quarzküvetten, werden während der Glasfaserproduktionsprozesse wie der Preformherstellung und dem Faserzug verbraucht.

Optikbereich

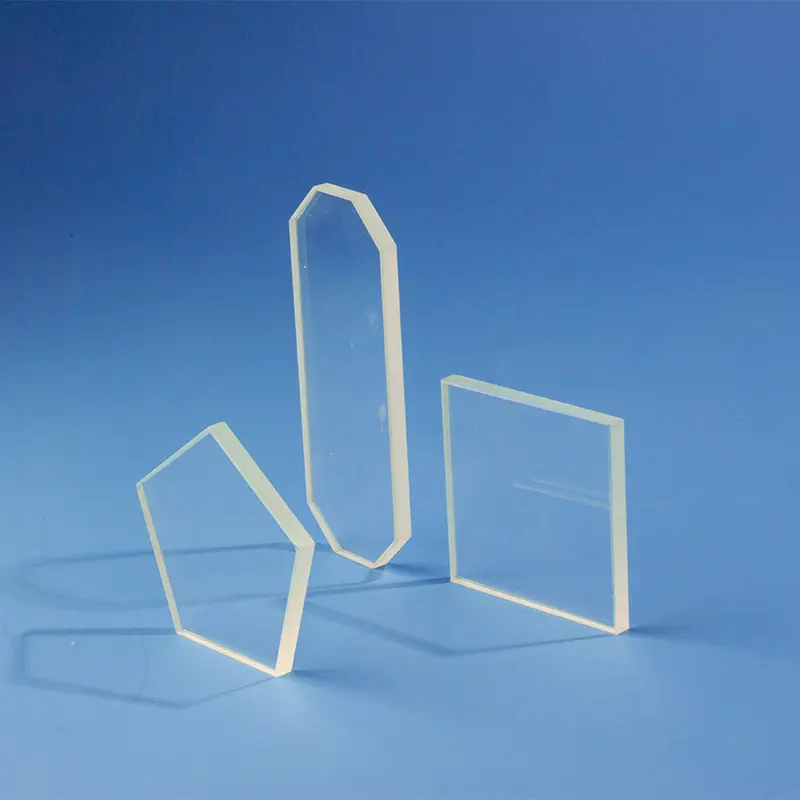

Aufgrund ihrer exzellenten optischen Eigenschaften werden Quarzglasplatten in der Herstellung von High-End-Optiklinsen, Prismen sowie als Substratmaterialien für TFT-LCD-Hochauflösungsdisplays und IC-Fotomasken eingesetzt. Sie gewährleisten eine Lichttransmission im Wellenlängenbereich von 185–3500 Mikrometern und bieten somit ein klares visuelles Erlebnis.

Luft- und Raumfahrt

Quarzglasplatten werden aufgrund ihrer geringen Dichte, hohen Druckfestigkeit und guten optischen Leistung in der Luft- und Raumfahrt für Satelliten und Raumfahrzeuge breit eingesetzt. Strahlungsbeständiges Quarzglas kann die Lage von Raumfahrzeugen effektiv steuern, und hochfeste, strahlungsbeständige Glasdeckgläser bieten effektiven Schutz für die Solarzellen-Energiesysteme von Raumfahrzeugen.

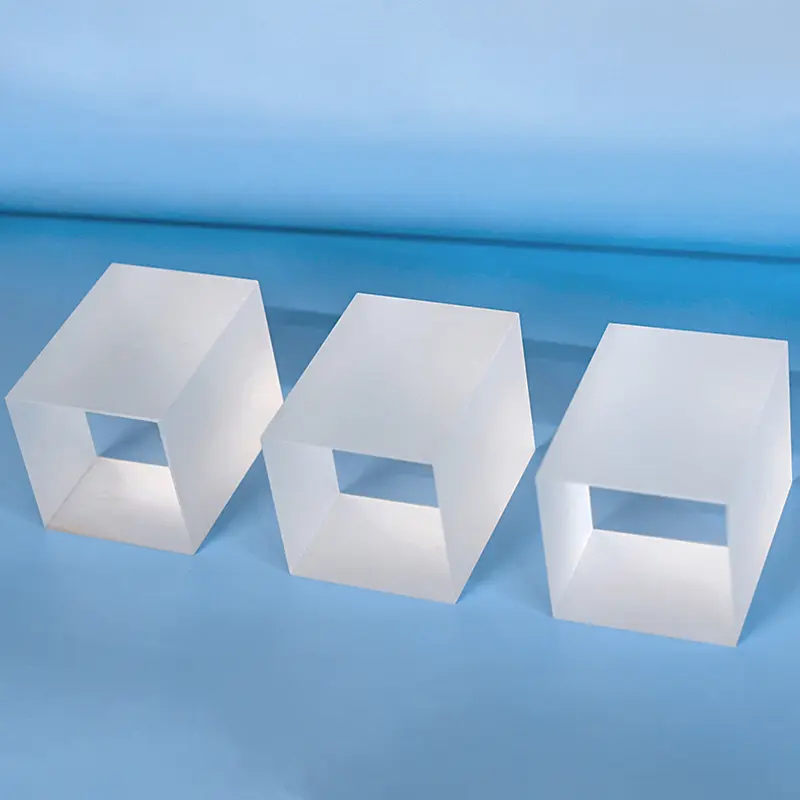

In der Halbleiterfertigung werden Quarzglasplatten zur Herstellung verschiedener Komponenten und Behälter verwendet, darunter Quarztiegel, Quarzboote und Quarzringe. Diese sind in Prozessen wie Reinigung, Oxidation, Photolithographie, Ätzen und Diffusion unerlässlich.

Quarzglasplatten weisen eine extrem hohe chemische Stabilität auf und zeigen gegenüber nahezu allen Säuren, mit Ausnahme von Flusssäure, eine Inertheit. Diese Eigenschaft macht sie in chemischen Laboren und industriellen Anwendungen sehr begehrt.

Ein niedriger Wärmeausdehnungskoeffizient bedeutet, dass Quarzglasplatten minimale Dimensionsänderungen bei Temperaturschwankungen aufweisen. Dies ist entscheidend für Präzisionsinstrumente und Hochtemperaturgeräte, die eine präzise Dimensionskontrolle erfordern, und gewährleistet Stabilität und Zuverlässigkeit auch unter schwankenden Temperaturen.

Häufig gestellte Fragen

Wir sind auf die durchgängige Fertigung von hochreinen Quarzglaskomponenten spezialisiert. Unsere Kernproduktlinien umfassen:

Quarzrohre & -stäbe: Eine große Auswahl an Durchmessern und Spezifikationen.

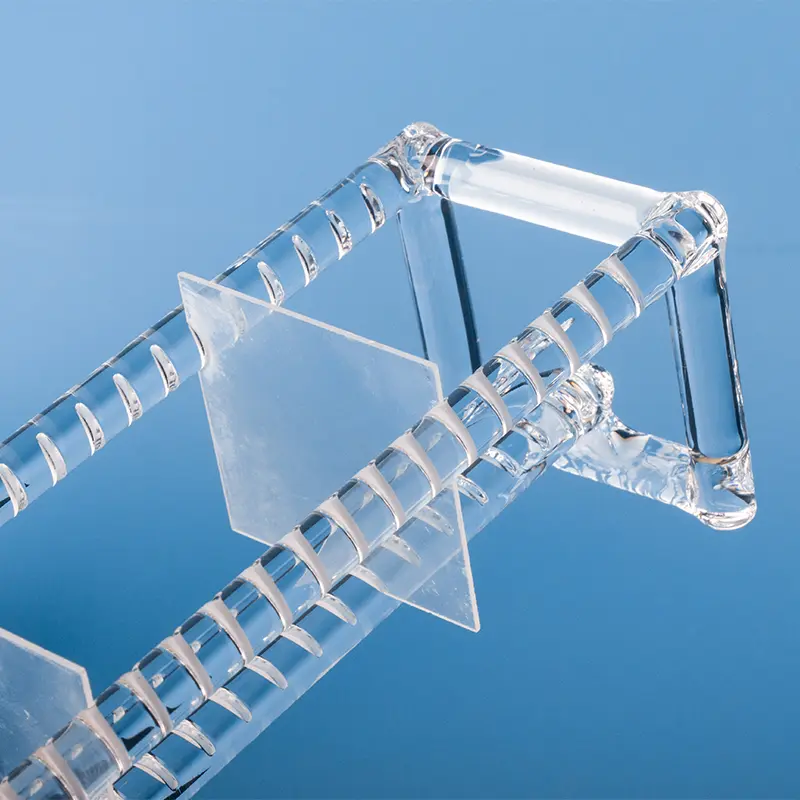

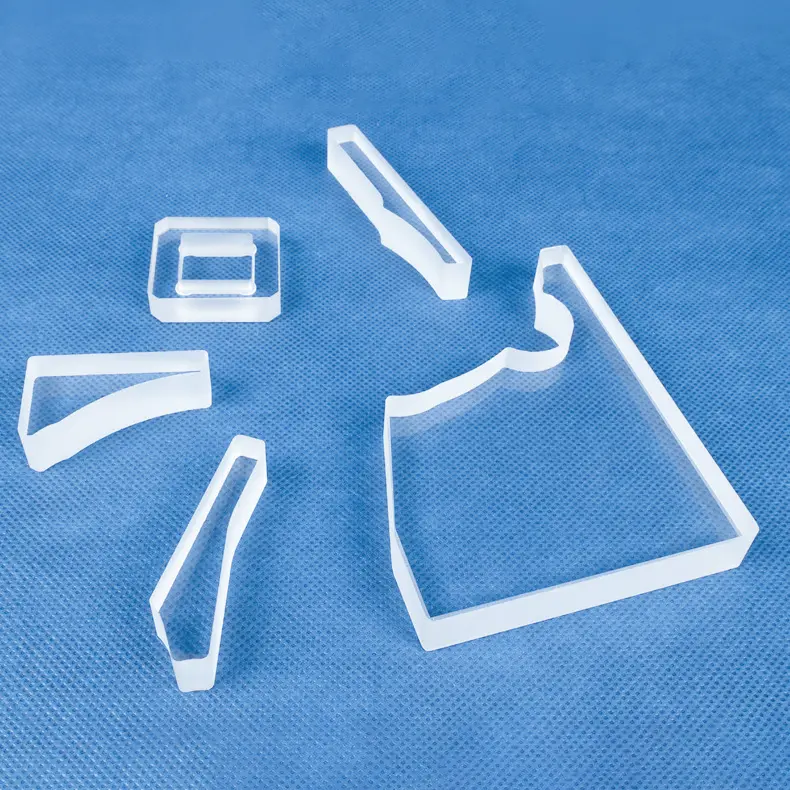

Quarzplatten & -scheiben: Präzisionsgeschnitten und poliert für optische und industrielle Anwendungen.

Quarzlaborglas: Ein komplettes Sortiment an Standard- und kundenspezifischen Glasgeräten, einschließlich Bechergläsern, Kolben und Booten.

Halbleiterquarz: Hochreine Komponenten wie Prozessrohre und Träger für die Halbleiterfertigung.

Kundenspezifische Fertigungskomponenten: Wir können komplexe Teile nach Ihren einzigartigen Designs und Spezifikationen fertigen.

Ja. Kundenspezifische Fertigung ist das Herzstück unseres Geschäfts. Mit über einem Jahrzehnt spezialisierter Erfahrung arbeiten wir eng mit Unternehmen zusammen, um erstklassige OEM/ODM-Dienstleistungen anzubieten. Unsere Kompetenzen umfassen Schweißen, Schleifen, Bohren, Polieren, Biegen und weitere Präzisionsbearbeitungstechniken, um Komponenten zu fertigen, die exakt Ihren Anforderungen entsprechen.

Qualität ist in unserem Herstellungsprozess von größter Bedeutung. Wir sind ein ISO 9001:2015 zertifizierter Hersteller, der sicherstellt, dass unsere Prozesse internationale Qualitätsmanagementstandards erfüllen.Unsere Produkte durchlaufen zudem rigorose SGS-Prüfungen hinsichtlich Reinheit und Leistung. Wir verwenden hochreine Rohmaterialien (bis zu 99,998% SiO2), um Quarzglas- und Kieselglasprodukte mit außergewöhnlicher thermischer Stabilität, hoher Temperaturbeständigkeit und chemischer Inertheit herzustellen.

Wir haben unsere Prozesse maximal effizient gestaltet:

Senden Sie Ihre Angebotsanfrage (RFQ): Senden Sie uns Ihre technischen Zeichnungen, Spezifikationen und Anforderungen über unser Kontaktformular auf der Website oder per E-Mail.

Schnelle Reaktion: Sie können eine erste Antwort innerhalb weniger Minuten und eine detaillierte Kommunikation innerhalb einer halben Stunde erwarten.

Design & Angebot: Wir liefern Ihnen innerhalb von 24 Stunden einen detaillierten Designvorschlag und ein wettbewerbsfähiges Angebot.

Prototypenentwicklung & Produktion: Nach Freigabe gehen wir zügig von der Prototypenfertigung zur Serienproduktion über, um Ihre Fristen einzuhalten.

Eine Partnerschaft mit Aoxin Quartz bietet mehrere entscheidende Vorteile:

Nachgewiesene Expertise: Mit über 10 Jahren Branchenerfahrung verfügen wir über das technische Fachwissen, um komplexe Herausforderungen zu meistern.

One-Stop Solution: We manage the entire production process, from sourcing high-purity raw materials to fabricating and finishing complex components.

Wettbewerbsfähiger Wert: Als Standort in einem wichtigen Quarzproduktionszentrum nutzen wir eine effiziente Lieferkette und fortschrittliche Fertigung, um außergewöhnliche Qualität zu einem wettbewerbsfähigen Preis anzubieten.

Dedicated Partnership: Over 90% of our clients become long-term partners. We are committed to your success through responsive service, reliable quality, and innovative solutions.